|

| HOME What's New

Camera Stuff

|

|

The Sound Story

The program Motion

does not include the ability to use sound, though it is something that

some of the members of the mailing list have talked about. I had

been

thinking about this for a while and started researching the

possibilities. I would have to attack this problem on two

fronts. One, build a stereo preamplifier to allow dual

microphones to feed the sound card and two, find a way to make

Motion capture sound.

Little did I know that finding a preamp

circuit would take months of testing circuits on a

breadboard before I found a circuit that would work well with my Aureal

8820 sound card on my aging Linux box. I built prototype

preamps with single

transistors. I

built preamps with a couple ICs and a few transistors. I think I have

looked at almost every microphone preamp on the web and I have built

many of them on a protoboard. With all of the preamps I

built, I found

myself going back to a simple circuit that was adapted from the data

sheet for the LM386N audio amplifier integrated circuit. This circuit

stayed built on a protoboard as a mono preamp so that I would have

sound on the mpegs I collected each day. In between

builds of other preamps I messed around with this one trying to get rid

of the noise in the circuit. In the end, I got rid of most of the

offending noise and even though it was by no means the most powerful of

the preamps I built, it was enough to get the job done. I also

came up with a simple way to

get rid of the nine volt battery that was used in these circuits.

I came up with the power circuit idea

after being frustrated by the fact that a 9 volt battery would only

last a couple of days running 24/7 and running an auxiliary power

supply introduced a lot of hum into the sound card. I was

thinking

about the problem one evening and thought that using the power supply

for the computer that the sound card was in would mean that the ground

circuit was common to both the amp and the sound card. Since

grounding issues are what usually introduce hum into an audio circuit,

this just might do the trick. I didn't have a 9 volt voltage

regulator on hand, but did have a LM317 adjustable voltage

regulator. I built a circuit using the schematic on the data

sheet and was pleasantly surprised when it turned out to be as quiet as

using a 9 volt battery. Pretty cool! One major problem

solved.

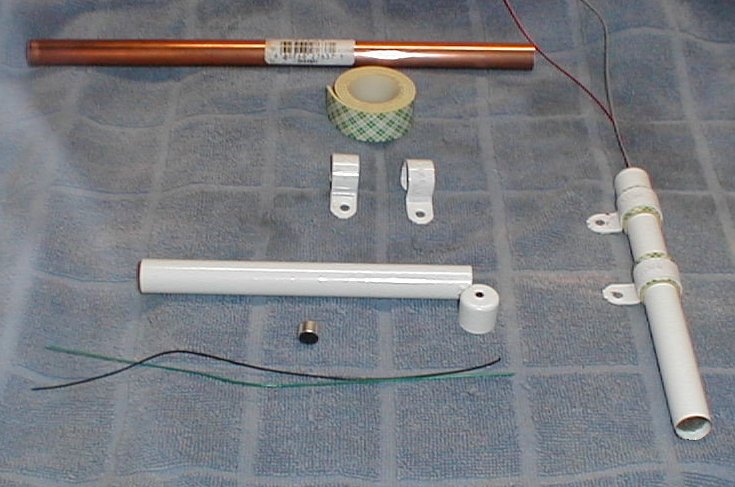

I went through a couple different ideas

on microphones. I started with a couple condenser mics from Radio

Shack. I mounted the mic capsule inside a metal tube for the

first try.

|

|

|

This ended up sounding -

well, like a microphone in a tube! Who would have thought?

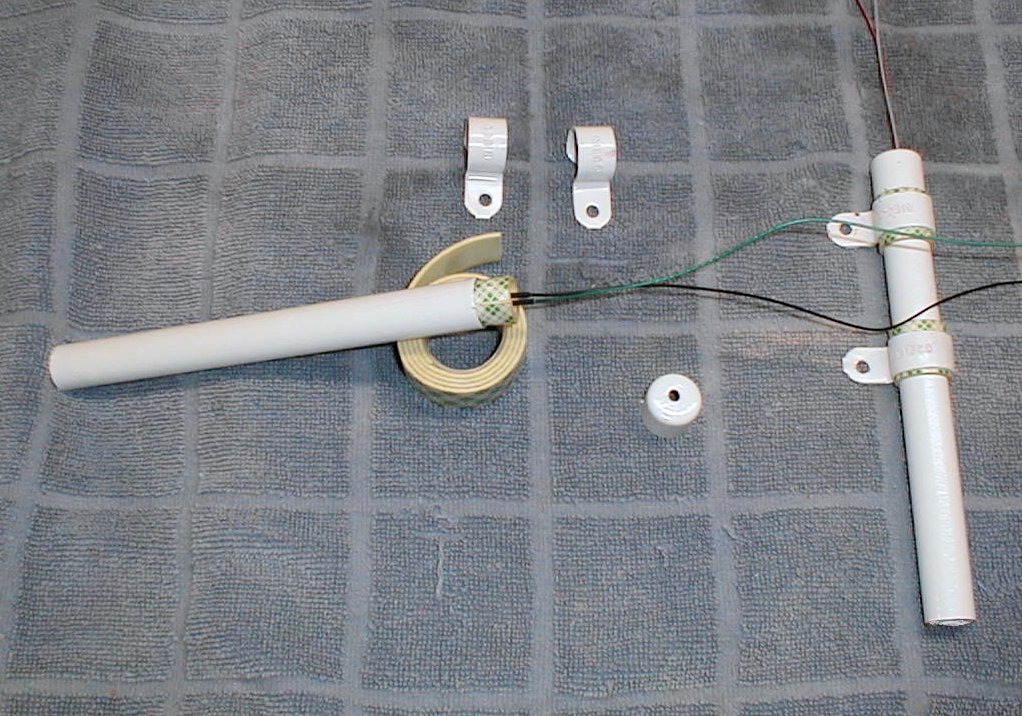

I then tried a different approach. I used the reflectors from a

couple cheap flashlights and put the microphone button in the area that

would have housed the light bulb. I cut out a mounting plate from

some scrap fiberglass and using an old radio controlled car builder's

trick, I dyed the fiberglass with clothing dye. Not only does it

look better, it works better as well.

|

|

|

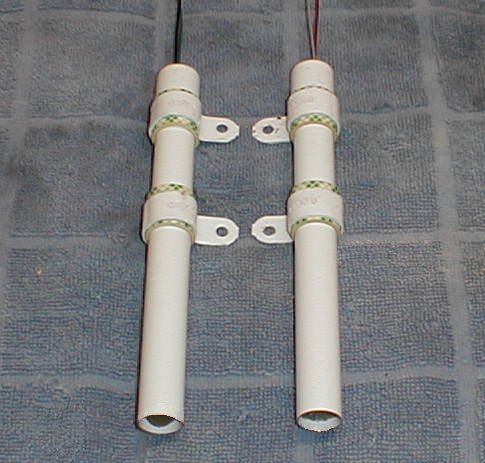

This mount will attach

behind the camera with the microphones below the camera housing.

The mics are angled so that they face out from center. This helps

a bit in being able to separate the left channel from the right.

My friend John tells me that the setup looks a bit lake a brassiere,

but I figure that's just wishful thinking on his part! The mics

are rubber mounted in the fiberglass and this does a bit to isolate the

mics from the rumble of the stepper motors. It also makes it

possible to angle the mics about 15° from perpendicular to

the mounting plate.

With the mics in a better

state, it was back to the preamp circuits. I came across a kit at

Jameco called the Super

Snooper and had high hopes for it, as it was designed to listen to

voices at a distance. Since my goal is to be able to incorporate

the ability to point the camera in the direction of sounds coming from

my property, I was hoping that this circuitry would be sensitive enough

to serve my purpose. The PDF file has a decent shot of the

circuit board, so it was pretty easy to duplicate the

circuit. This circuit uses a LM386 audio amp and a LM1458 OP-Amp

along with a condenser mic. Unfortunately, it didn't produce a

whole lot more sensitivity than using the LM386 alone. I was a

bit surprised that the Jameco kit did not make use of jumping pin 1 and

8 of the audio amp to increase its output - though the circuit board

does have traces provided to add a 10µF cap to increase the

voltage gain to 200.

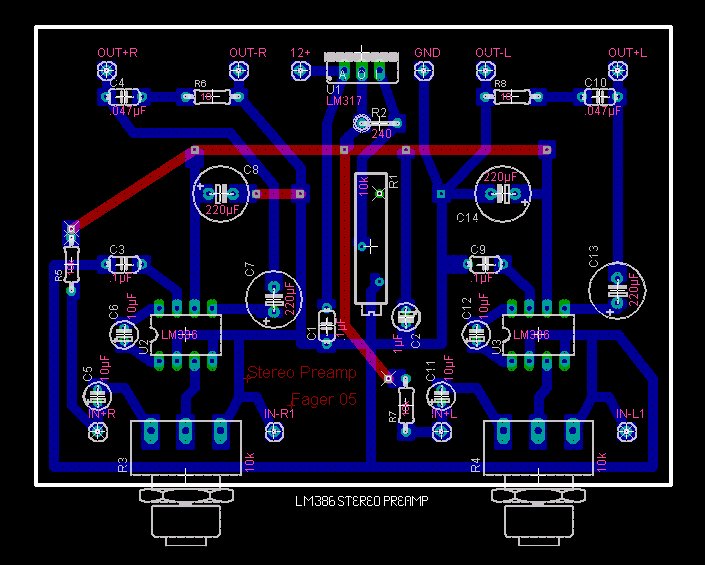

So it was back to the

drawing board, or in this case Eagle software's Eagle 4.14 light

to draw up another circuit. At the same time, I started doing

some reading on how to etch circuit boards. There are a couple

types of kits available for etching circuits on copper clad circuit

boards. Radio Shack sells one with a Sharpie permanent marker so

you can draw your layout, then etch away the un-needed copper with the

supplied Ferric Chloride solution. This may work well for very

simple circuits, but the pen doesn't draw a sharp enough line for

circuits where the traces will be very close together.

Another choice is to use

one of the kits from Jameco or Allied Electronics that use a

photo-sensitive coating on their copper clad blank boards. For

this type, you design your circuit using a tool such as Eagle 4.14

lite, then print it to a transparency, then place the transparency over

the board and expose it with either sunlight or a UV lamp, then

develop the board and finally etch it with either Ferric Chloride or

Ammonium Persulfate. This supposedly gives much better results,

but I had read about using circuits printed on special paper with a

laser printer, then ironed on to the circuit board blank. This

works because the toner used by the laser printers is a powered

plastic. When heated, the powder melts and forms a thin plastic

film over the paper in the shape of each character. As long as

you use a paper with a slippery finish, such as photo paper, applying

an

iron to the back side of the paper will transfer the plastic image to

the circuit board blank. This sounded like it would be the easiest way

to go.

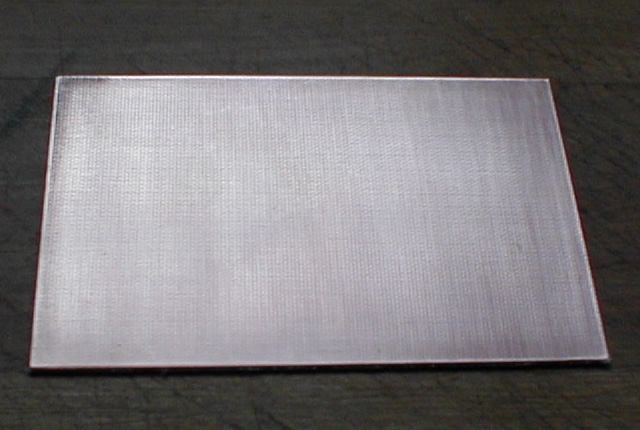

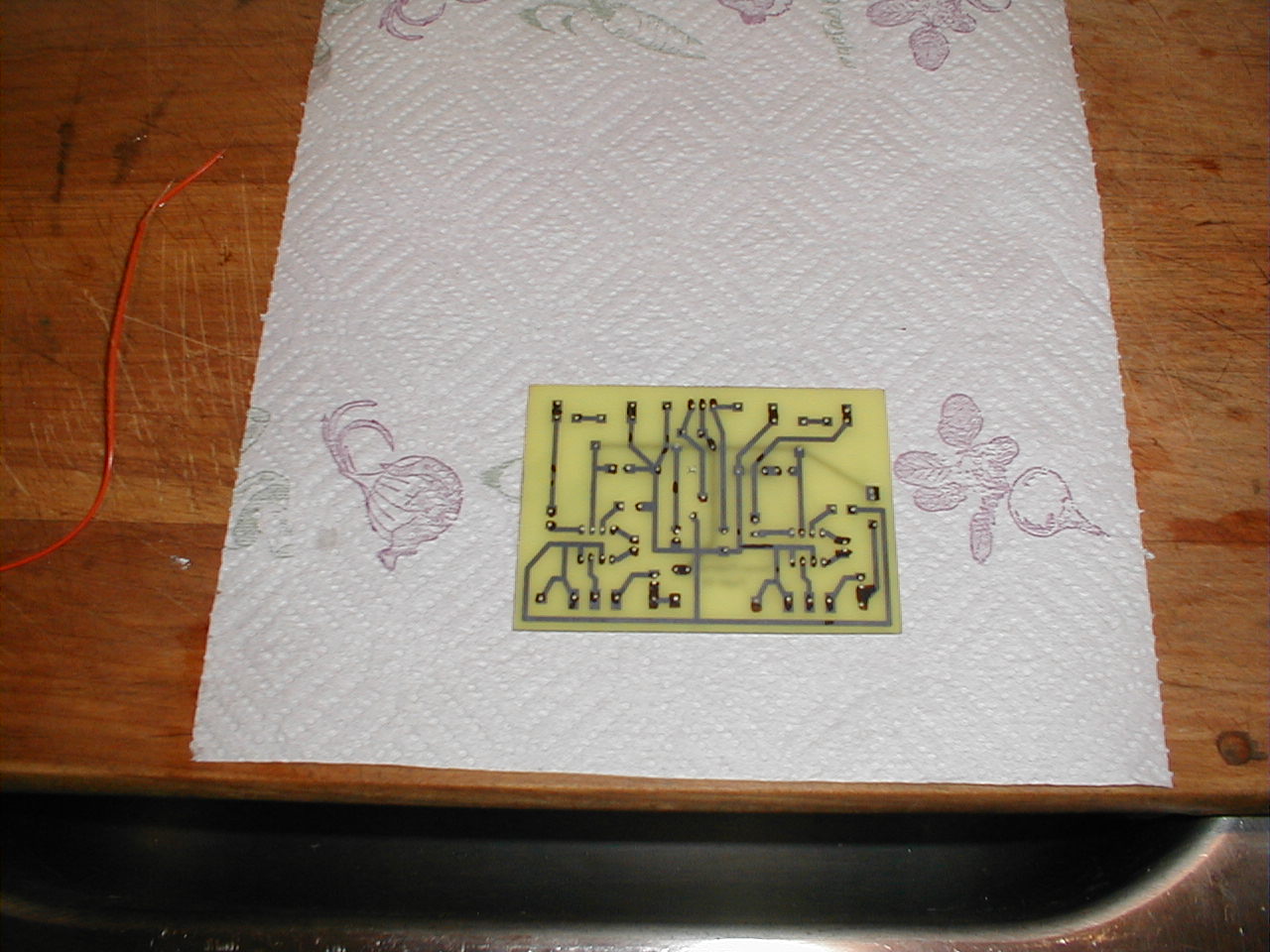

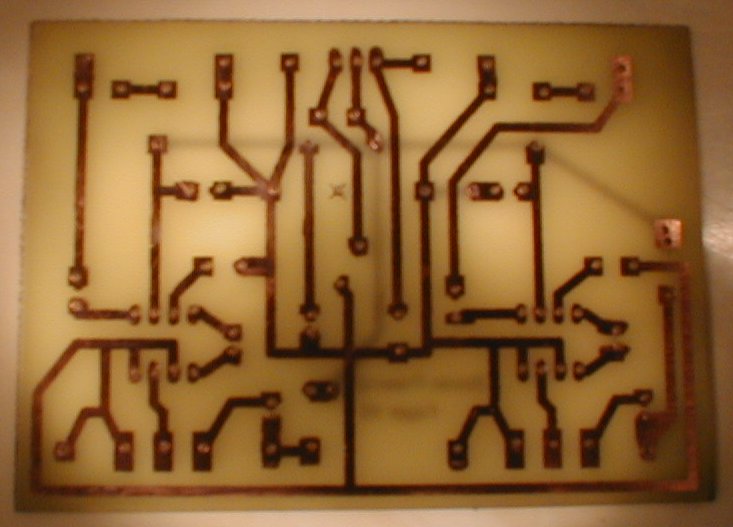

I purchased the Radio

Shack etching kit. Once I opened the package and looked at the

board blanks, I noticed that instead of being totally smooth, they had

a texture to them. I though that this might prevent the process

of ironing the printed circuit to the board from working

properly. The "fix" was to use some 400 grit wet and dry

sandpaper, then some 800 grit, to sand the board as flat as I could get

it. This took about 15 minutes of sanding with water to wash away

the copper particles to get the 3.5 X 5" board nice and flat. The

sanding is also a good idea to clean the oxidation from the board

before trying to etch it. Below are the before sanding and after

sanding shots. It was tough getting the bumpy surface to reflect

with a flash, so I tried without one. If you enlarge the

pictures, you will get some idea of the difference.

|

|

I am no electronic

designer, but through all of the reading about audio circuits I have

been doing for the last couple of months, I am beginning to come up

with some designs that do what I need. The design I just

finished drawing up puts the capacitors and the volume control pots

very close to the IC chip to keep down the noise a bit. I am

getting a little better with positioning components on the board to

keep the layout compact, but I still have a way to go in that

regard. I enjoy working with circuits and think that I will spend

some more time learning when I finish up with this project. I

have read a bit about PIC microprocessors and think I would like to

spend some time getting familiar with them. Ah, so many interests

and so little time!

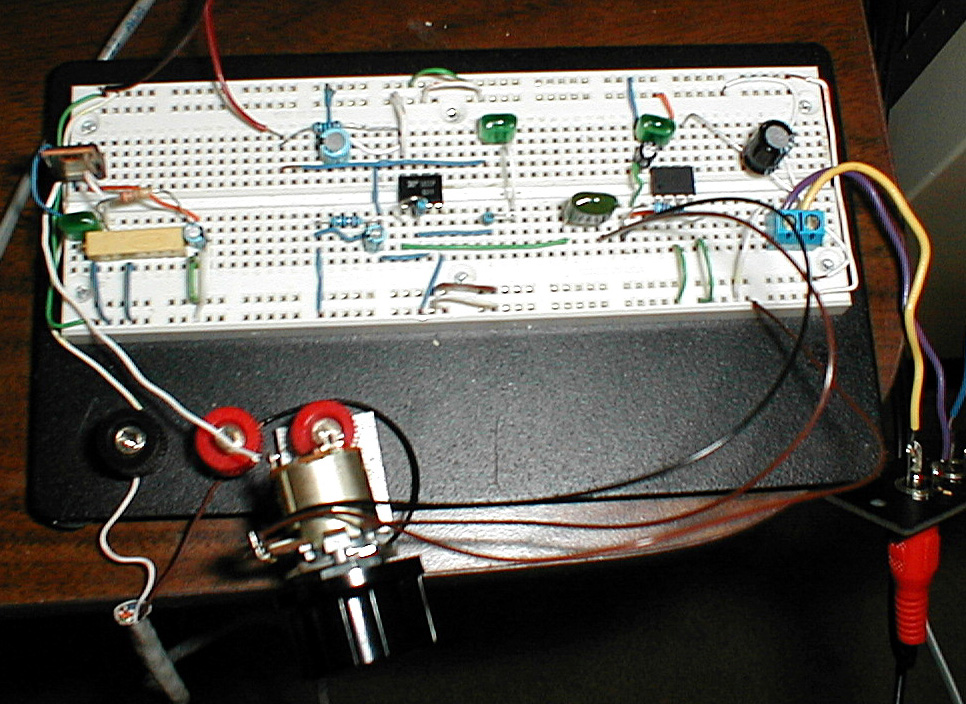

The next circuit I decided

to build was fairly simple compared to some of the earlier attempts,

but it was a design that had worked well at the breadboard stage,

unlike the "Super Snooper circuit that I borrowed from Jameco and the

two transistor amp circuit I found on an audio site. Below is the

Super Snooper circuit on a breadboard on the left, a quick and dirty

perf board two

transistor circuit and the final board design for the stereo LM386

board on the right.

|

|

|

Back to the etching of the

circuit board. After getting the board flat, I cleaned it with

steel wool and an automotive prep solvent which is used to prepare body

work for paint. It strips off waxes and whatever else without

being too harsh. I had placed some drilling guides on the board

and drilled four holes to allow me to line up the top and bottom

circuit templates. This is a good idea if you want the top and

bottom circuits to line up with each other. I used a size #62

drill bit which is .038" (.9652 mm). Be forewarned, they are

quite easy to break.

My wife took the artwork

to work along with a couple of sheets of Epson All-Purpose Glossy

Paper, # S041654, and used their laser printer to print my circuits to

the shiny side. I then punched 4 holes in the bottom template,

which didn't need to be reversed for the printing, and in the top

template, which did need to be flipped over by Eagle 4.14 to print

properly. Starting with the bottom, I lined it up using

toothpicks and pressed the iron in the center of the paper to get the

toner to stick to the copper. Once the center is stuck down,

removal of the toothpicks allowed me to finish ironing the circuit

pattern to

the copper. I used just below linen on the iron's heat scale and

pressed down hard with the tip of the iron. It is possible to

gently pull back the paper to see if the toner is going on completely

or whether there are still bits attached to the paper and then return

it to its aligned place, but it is very hot. Once the transfer

has been achieved, you can move to the top circuit. Do NOT remove the

paper from the bottom while ironing the top or the toner will attach

itself to whatever is under the board. The paper has a wax-like

coating on it, so the paper doesn't stick to the board. Unlike

some of the instructions I read on the web, I didn't need to soak the

paper in water to get it off of the copper.

|

|

|

Once the ironing is

complete, let the board cool and remove the paper. Clean up your

mess (It's probably not YOUR iron, right?) and then touch up any areas

where the toner did not adhere with a Sharpie or other permanent marker

with a fine tip.

I then tied some string

through one of the holes I had drilled and stuck the board into the ferric chloride that had been

warmed up to about 100°F by sticking the bottle under some hot tap

water. I continuously agitated the solution and checked the

progress every few minutes. Even though this was the second time

I had used the solution, the etching went pretty quickly. I would

guess that it took about 10 to 12 minutes for the copper to be totally

dissolved.

|

|

|

After cleaning the board

under running water and some dish soap, I cleaned the toner and Sharpie

ink from the traces with some lacquer thinner. The Radio Shack

kit

comes with some solvent to clean off the ink, but I already had the

lacquer thinner out and it worked so well, I didn't bother trying their

solvent. I'm pretty impressed with using photo paper and an iron

to transfer the toner to the blank circuit board. It did such a

good job that the printing that I placed on the front of the board was

sharp and clear. That's pretty neat considering that the letters

were only 1/10th of an inch tall. For my first attempt at using

this method, I consider it a complete success and can't even think of

anything I could try the next time to make it better - except for

planning better circuits. It turned out that my plan to solder

both volume control pots directly to the board wouldn't work. I

had miss measured the depth of the case by an inch. I have no

idea how I did that, but the board would not fit if I soldered the pots

to the bottom of the board as planned. I ended up having to mount

the board to the bottom of the case and attach the pots to the face of

the case and run short lengths of shielded wire between them.

It's not quite as clean looking as I had hoped - even though no one but

me will ever look inside the case.

Stuffing the board with

parts went quickly and the soldering was easy, thanks to finally

replacing the worn out tip of my soldering station. My concerns

that having to move the two pots from being soldered directly to the

board to being attached by a couple inches of shielded cable would

introduce some noise into the circuit were

unfounded. The circuit is remarkably quiet. The sensitivity

and clarity of the sounds it picks up are pretty good. With the

pair of mics mounted on the camera outside the computer room window and

that window shut, I can hear the radio being played at moderate volume

inside the room. I asked my wife and son to have a conversation

on the driveway and had no problem listening in, though that's only

about 40 feet away from the microphones. The separation between

the channels is good. It is easy to tell what direction cars

are moving when they pass the house.

Even though this phase of

the project, or should I say the project within a project, has taken a

lot longer than I had originally envisioned it would, I'm quite pleased

with the outcome. Besides accomplishing the task of building a

microphone preamplifier, I've learned quite a bit about amplifier

circuits, become pretty proficient working in Eagle 4.14 lite, and

learned a new (for me) method for producing a pretty good looking

circuit board.

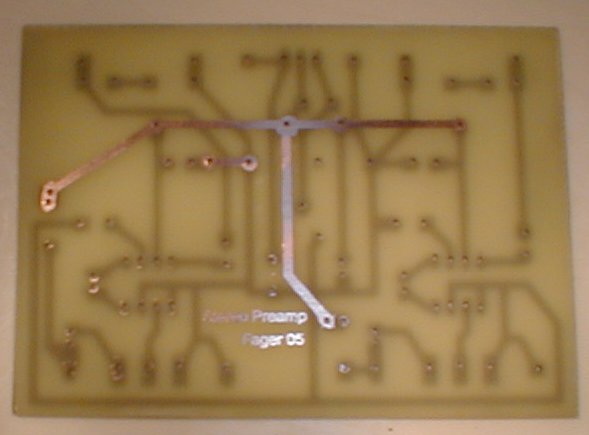

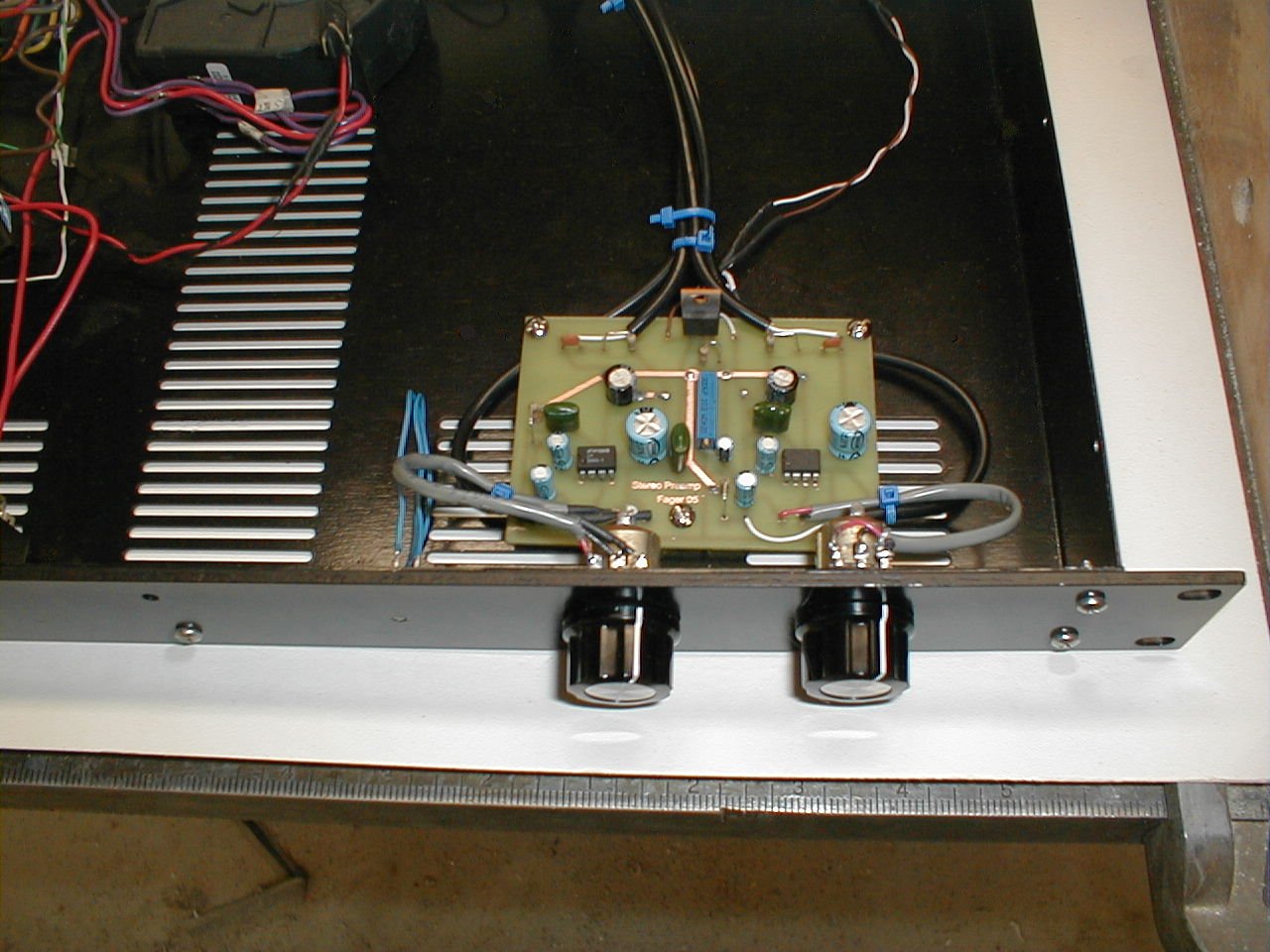

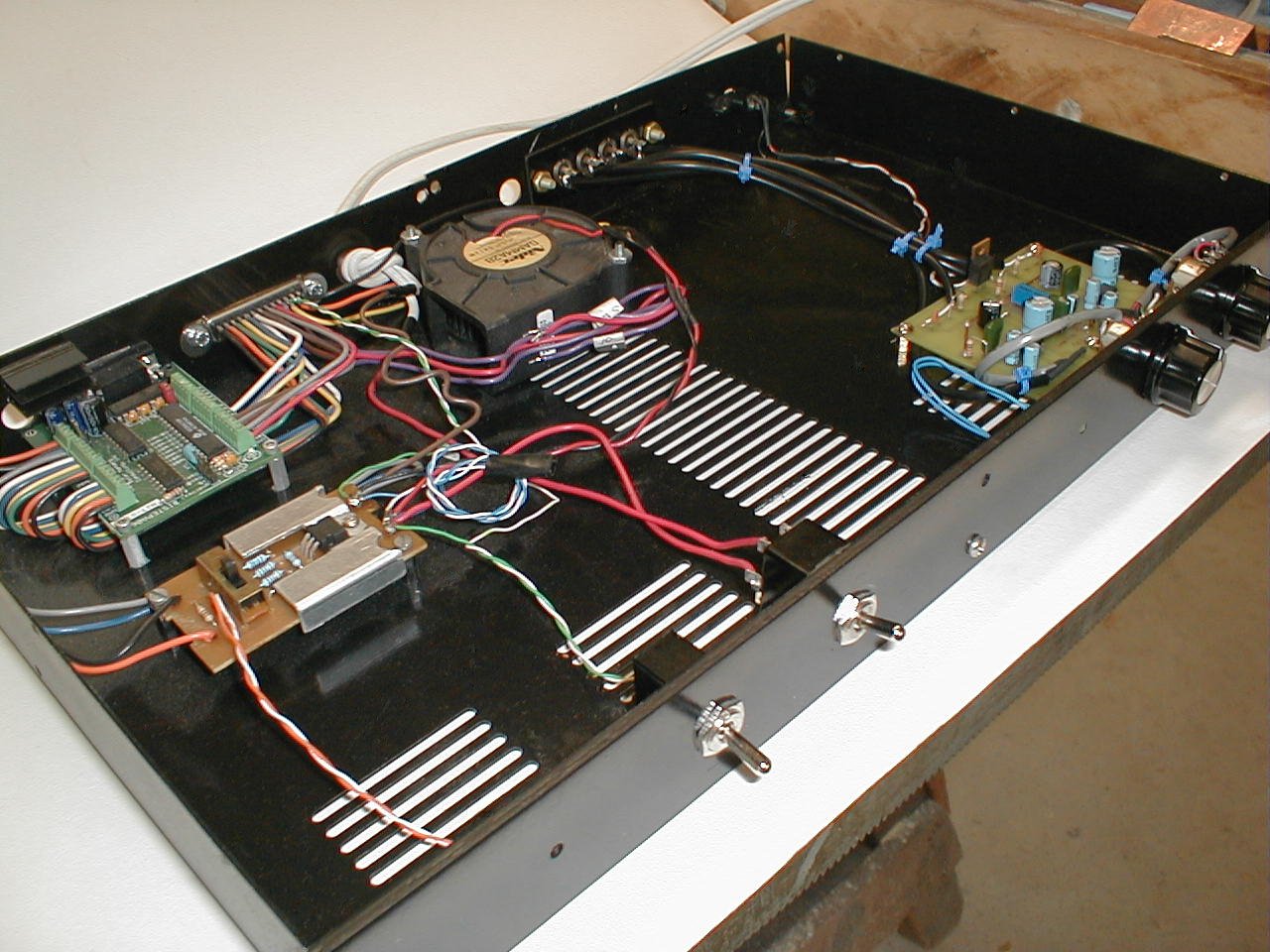

Below, left to right: 1)

You can see how well the top and bottom layers of the circuit board

line up. 2 & 3) The preamp takes its place in the little 1U rack

case, along with the BiStep A06 stepper motor controller and a multiple

output voltage regulator. There's still a lot of room in this

case. I just have to figure out what else needs to go in there.

|

|

|

|

|

|

|

|

|

|

|

© Fager 7-31-05