|

| HOME What's New

Camera Stuff

|

|

|

With the

tilt housing essentially done, I turned my focus to the bracket that

would hold it. This was cut from some 1/4" X 2" aluminum flat

stock that I had from the days of playing with water cooled and peltier

assisted cooling for computer processors. I drilled a 0.250 hole

through 2 pieces of stock and temporarily held them together by forcing

a 1/4" brass tube through them. This allowed me to shape both

pieces at once and keep them pretty near identical. |

|

Here I have rounded the corners

with the 10 inch disk sander attachment for my table saw. That

sander is a time saver. |

|

After cutting the base and

drilling and tapping a couple of 4-40 holes, I took the pieces

out to the buffing wheel and polished up the aluminum. It never

ceases to amaze me how much of a shine you can get from polished

aluminum. I added 5 ore holes in the base for the 0.2502" shaft and coupling. |

|

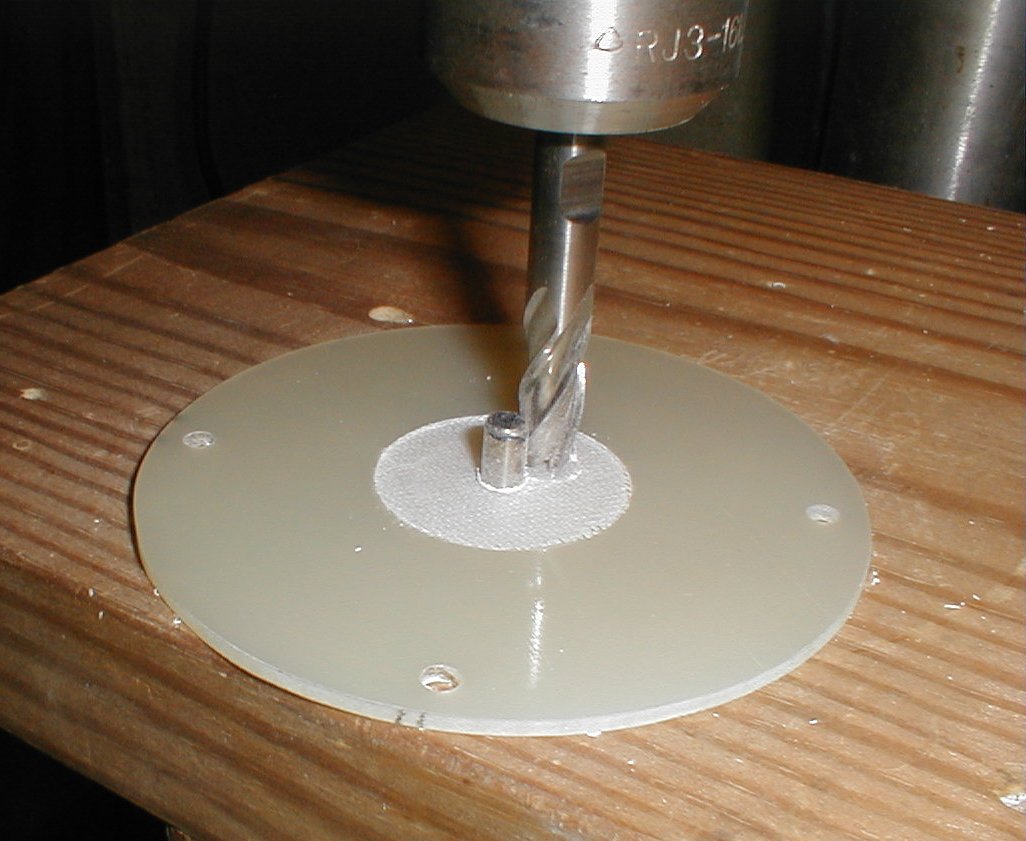

Time to get started on the "Pan" housing that will allow the camera to

rotate from left to right. I had found that using "all-thread" or

all threaded rod and stacking plates was the easiest way to build a

modular assembly. Using a couple of nuts to lock each layer in

position allows for an infinitely adjustable housing. This is

really helpful when you are designing as you go and are not sure of the

final dimensions. The first cut was for the stepper motor. |

|

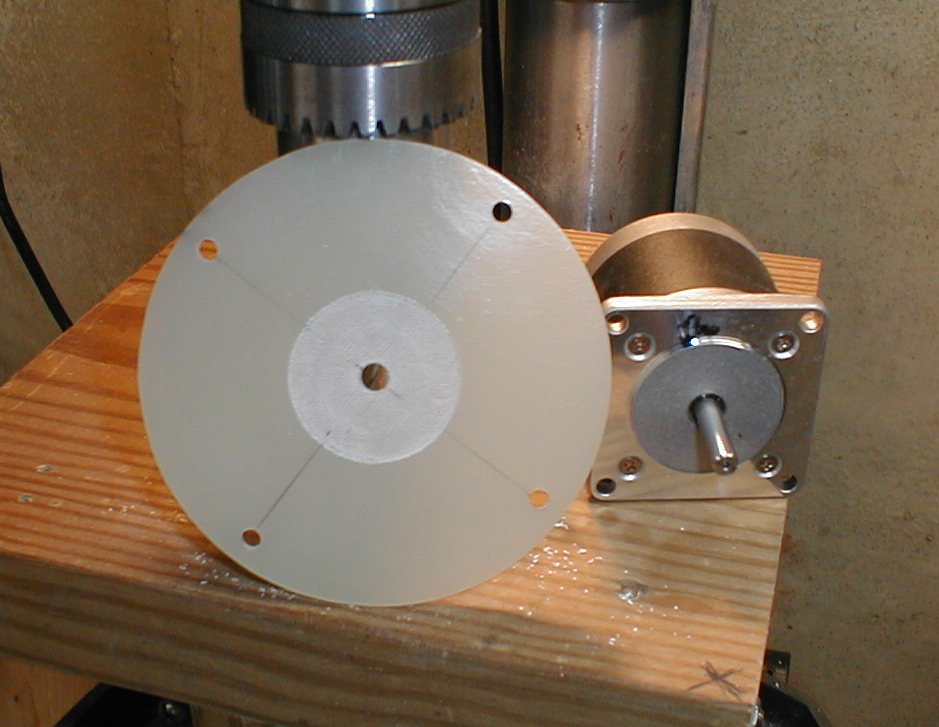

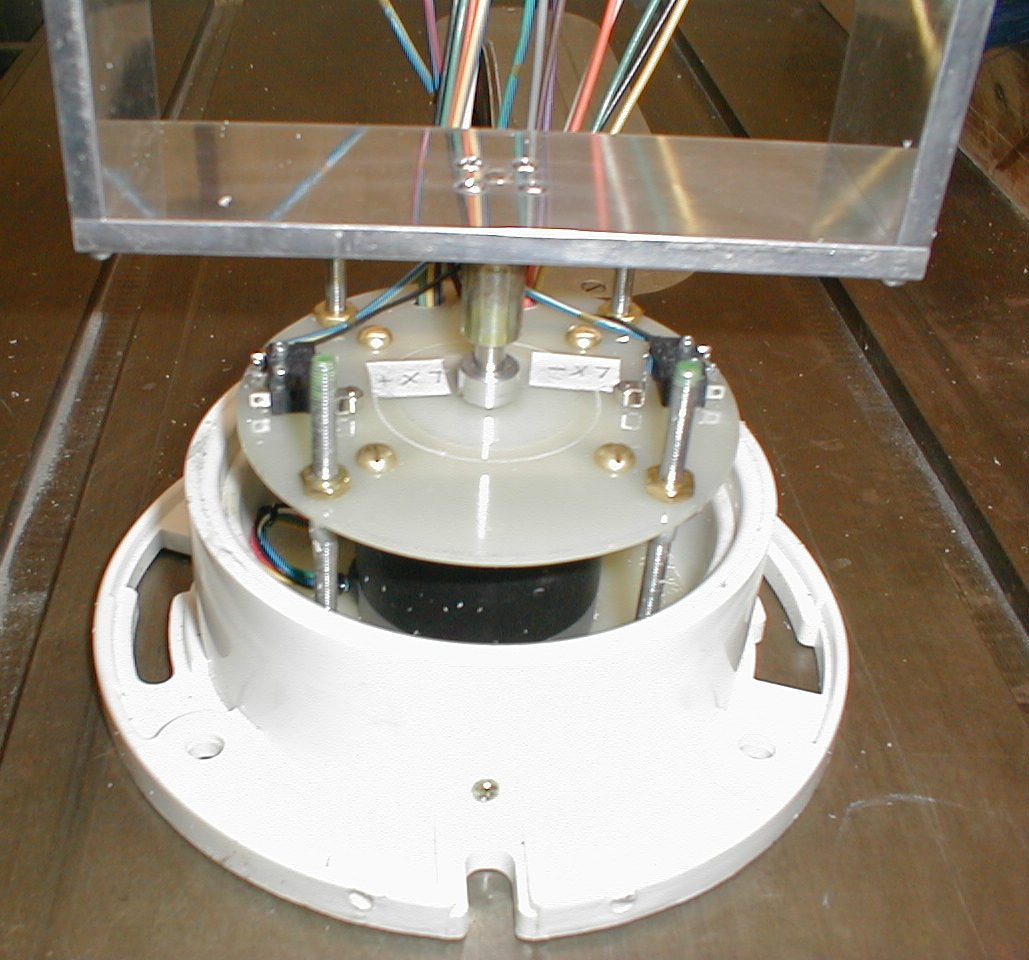

The "next to top" plate is finished. The left lower hole is a

little off, but still usable. |

|

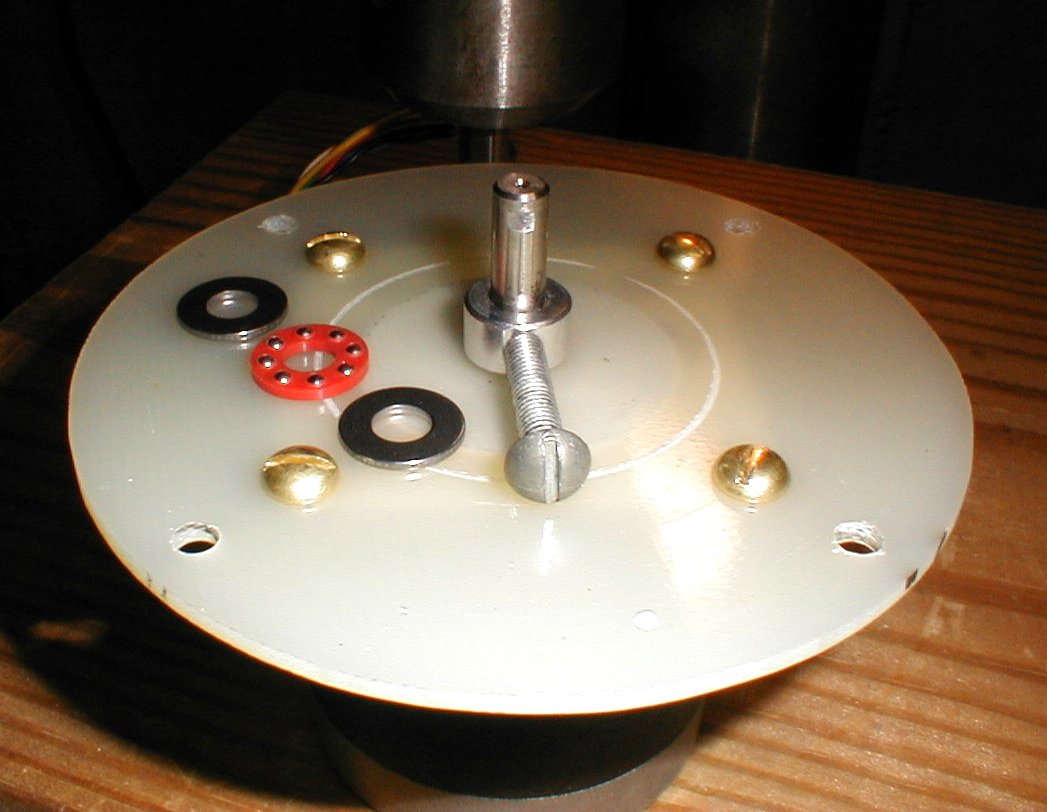

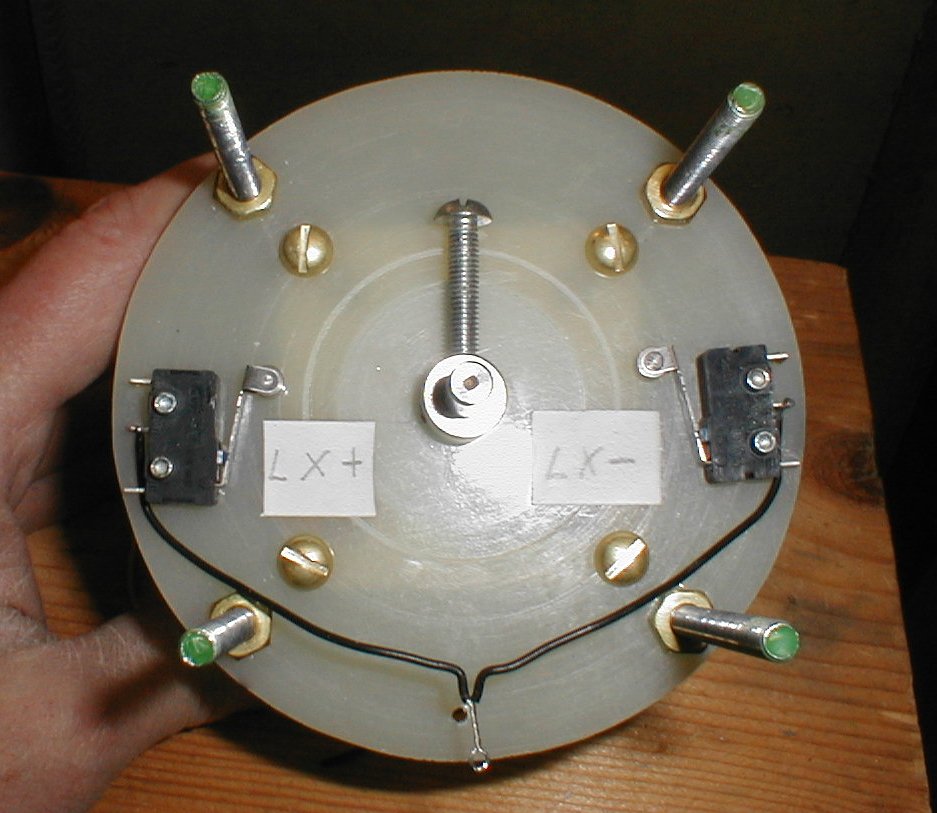

The

collar with the screw will turn the limit switches on and off.

The two washers and red bearing will hold the weight of the tilt

assembly and camera and allow it to rotate smoothly. |

|

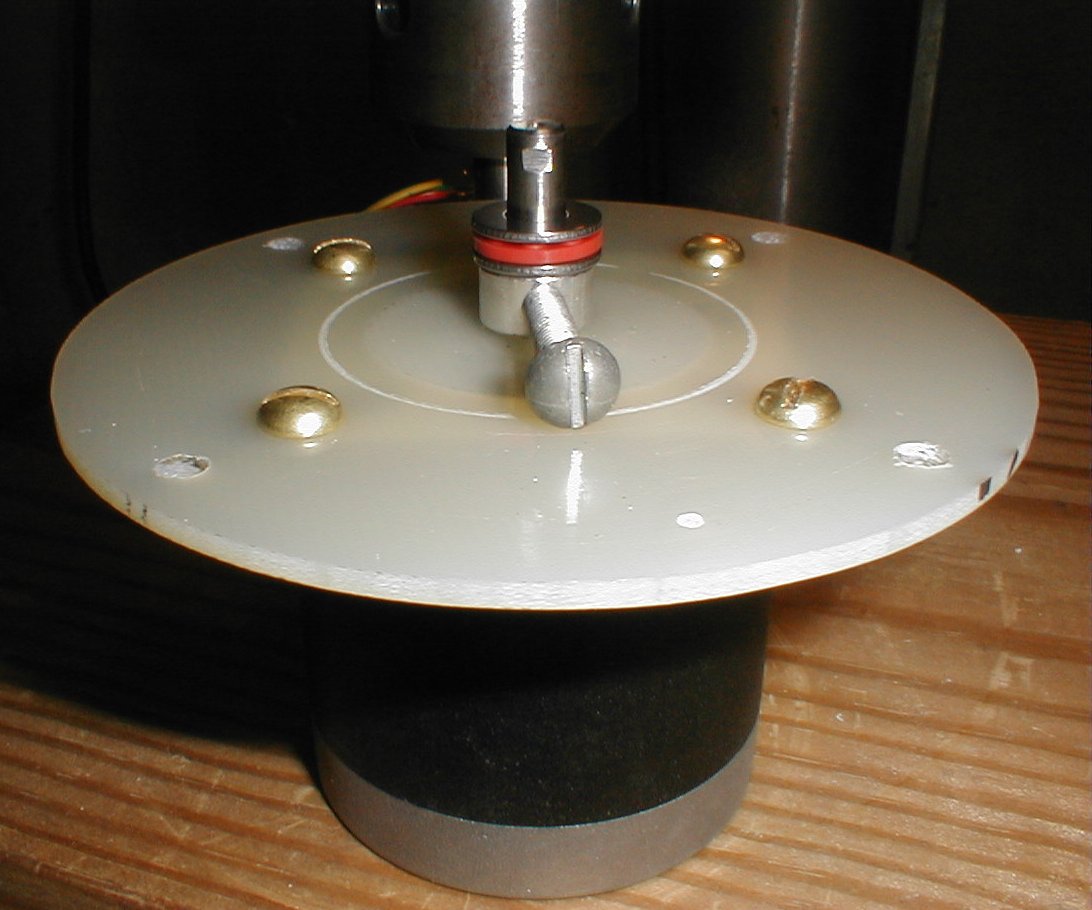

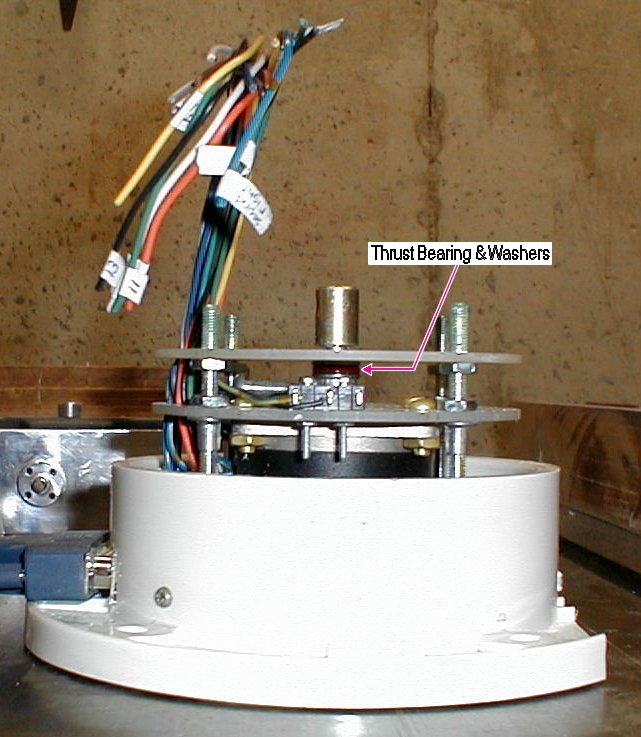

Here is a shot of the thrust

bearing temporarily installed. The top plate will go above the

bearing. You can see the "flats" I filed in the shaft that will

give the set screw a place to cinch against. |

|

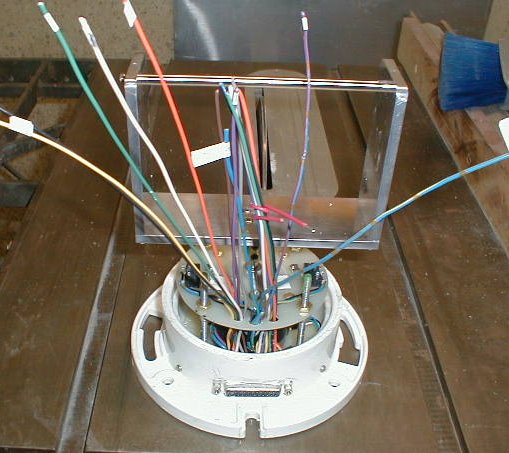

Here the all-thread has been installed, along with the limit switches

and the stepper motor. The further away from the center shaft that the switches are mounted, the more and finer adjustments that can be made on the limit switches. A small cam lobe would have made for a nicer looking setup, but the long screw allows me to position the stop switches more accurately. |

|

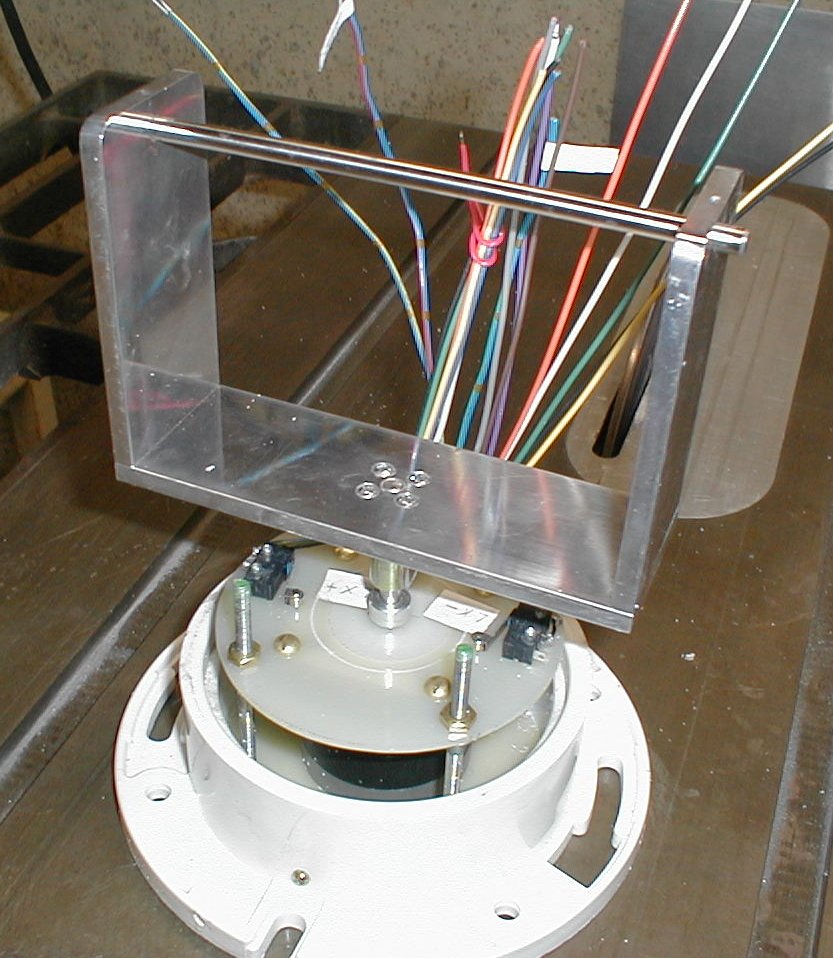

Here's the top view. It's not shown here, but I ended up flipping the position of the switches after I got the pan assembly finished. Once they were flipped over, it gave me about 200° of rotation before the limit switches would stop the camera from turning. |

|

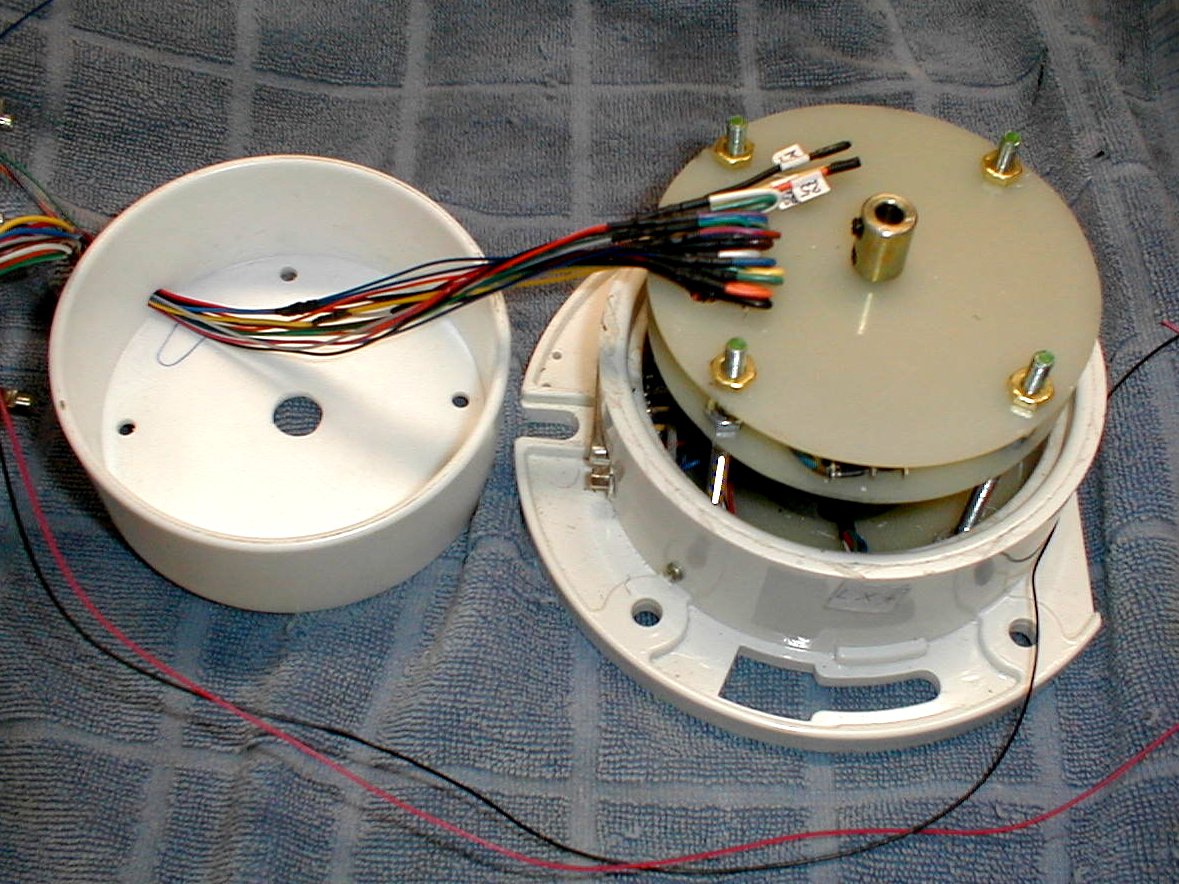

Now you can see the position of the thrust washer. If you imagine

the whole assembly turned upside-down, you can imagine how the thrust

bearing will hold the weight of the camera and tilt assembly. It

is not a large bearing, but the action of turning the camera is quite

smooth. The thrust bearing also saves the motor bearings from

having to take any vertical forces. There are quite a few wires that needed to be attached here. If you look at the lower right of the white plumbing flange (for holding toilets, no less!), you can see the side of a parallel port connector. Of the 25 possible connections on the connector, I used 22 of them. Numbering the wires was a must. |

|

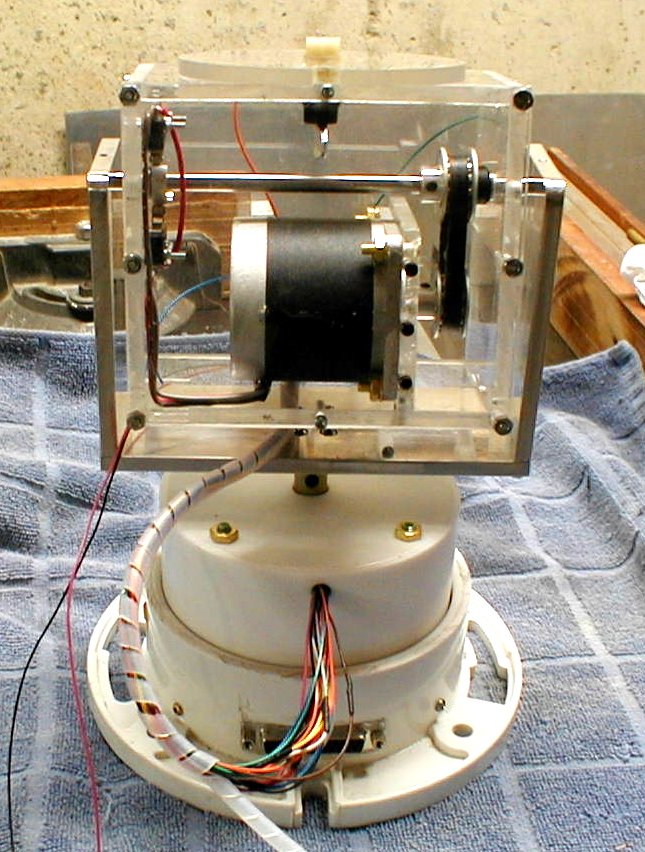

Here, another plumbing supply is used as the cap for the pan

assembly. The coupler visible on the top plate just protrudes

through the cap. Before the camera went outside, I fitted a seal to the end cap to prevent moisture from entering past the coupling. I also used silicone sealer on the mating surfaces. While it was not water-proof, it is pretty weather-proof. We had a couple of "gully-washer" rain storms after I had the camera mounted under the eaves of the house. I pulled the camera and checked for leaks. I was happy to see that there were none. |

|

A shot of the tilt bracket being test fit. The 25 pin connector

is plainly visible in this shot. |

|

Another view. |

|

Last chance to adjust things before the cap goes on. Time to do

some more soldering. |

|

The cap goes on after all the wires have been soldered and

routed. A plug is test fit to make sure that all is well before

using some silicone to seal up the connector. |

|

The tilt assembly gets fit and wired up. Rubber grommets will be

used where the wires enter the housings. Some cable wrap is used

to bundle up the wires a bit. The two thin wires will be used to turn on an off a relay that I installed inside the camera. This allows me to turn on and off the 104 infrared LEDs. The relay only consumes about 10 milliamp, so the wires don't need to conduct much current. |

|

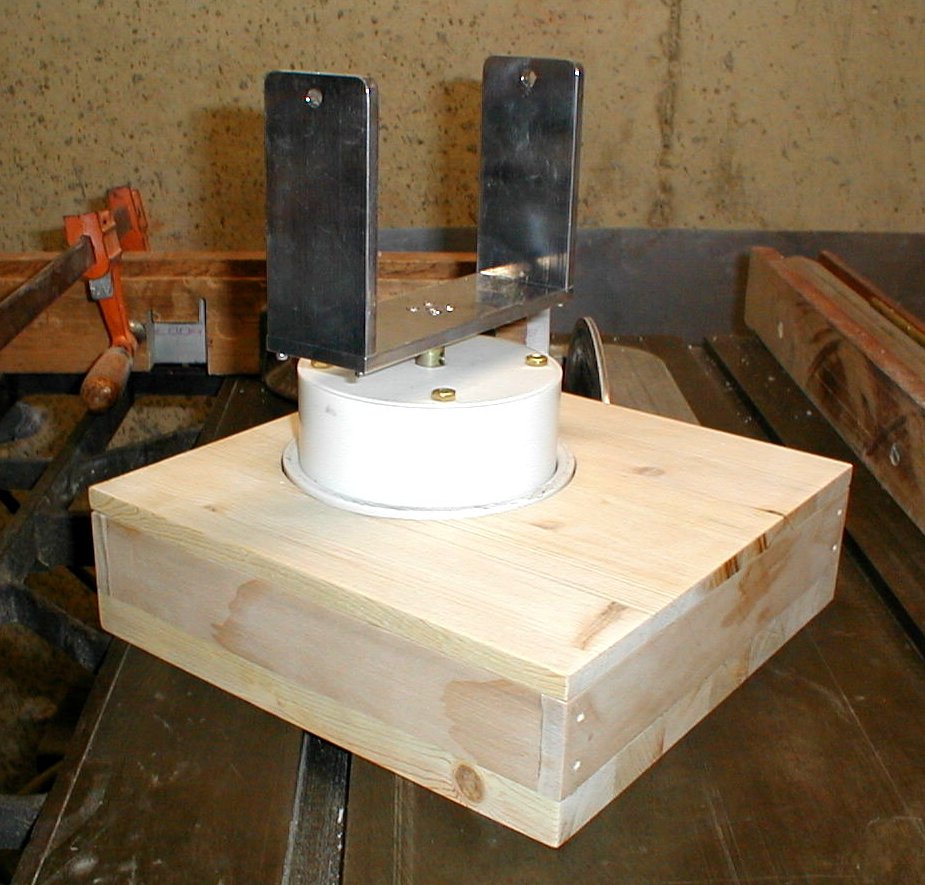

To weather-proof the pan assembly, the whole thing is places inside a

wooden box. Cutting fiberglass, then using the same blade to cut

wood results in a poor cut. You can see the heat marks.

Since I was just painting the box with some house paint, I wasn't too

concerned, but I really should have switched to a fresh blade for the

woodworking. I think that's called lazy! Yes, this picture is out of order in terms of when the box was built, but made more sense when trying to give some order to the project. |

|

A shot of an almost complete project. A little paint, and .... |

|

One

last shot before painting. |

|

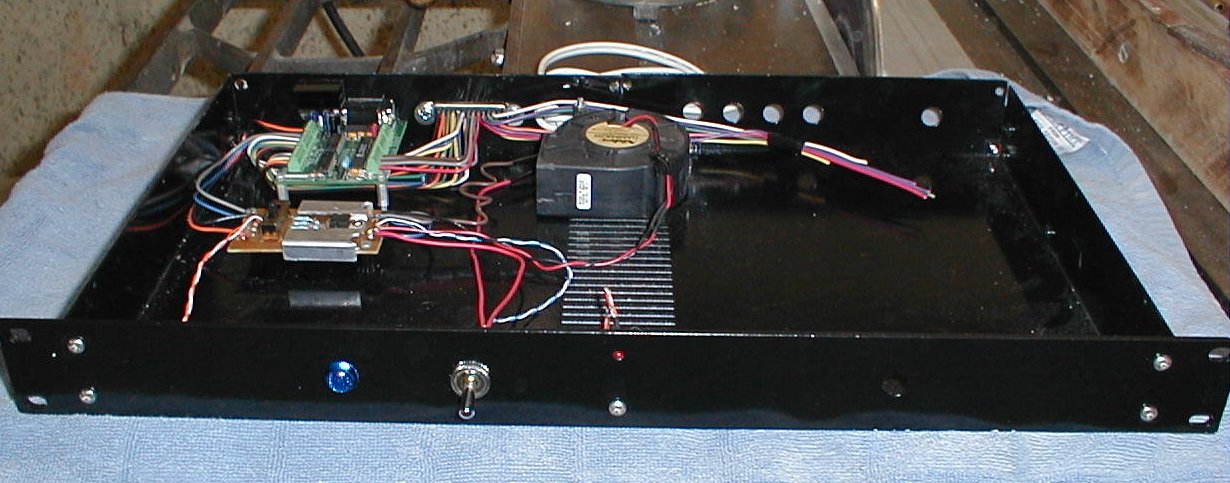

An early shot of the stepperboard controller after installing it in the

little 1U rack case.. |

|

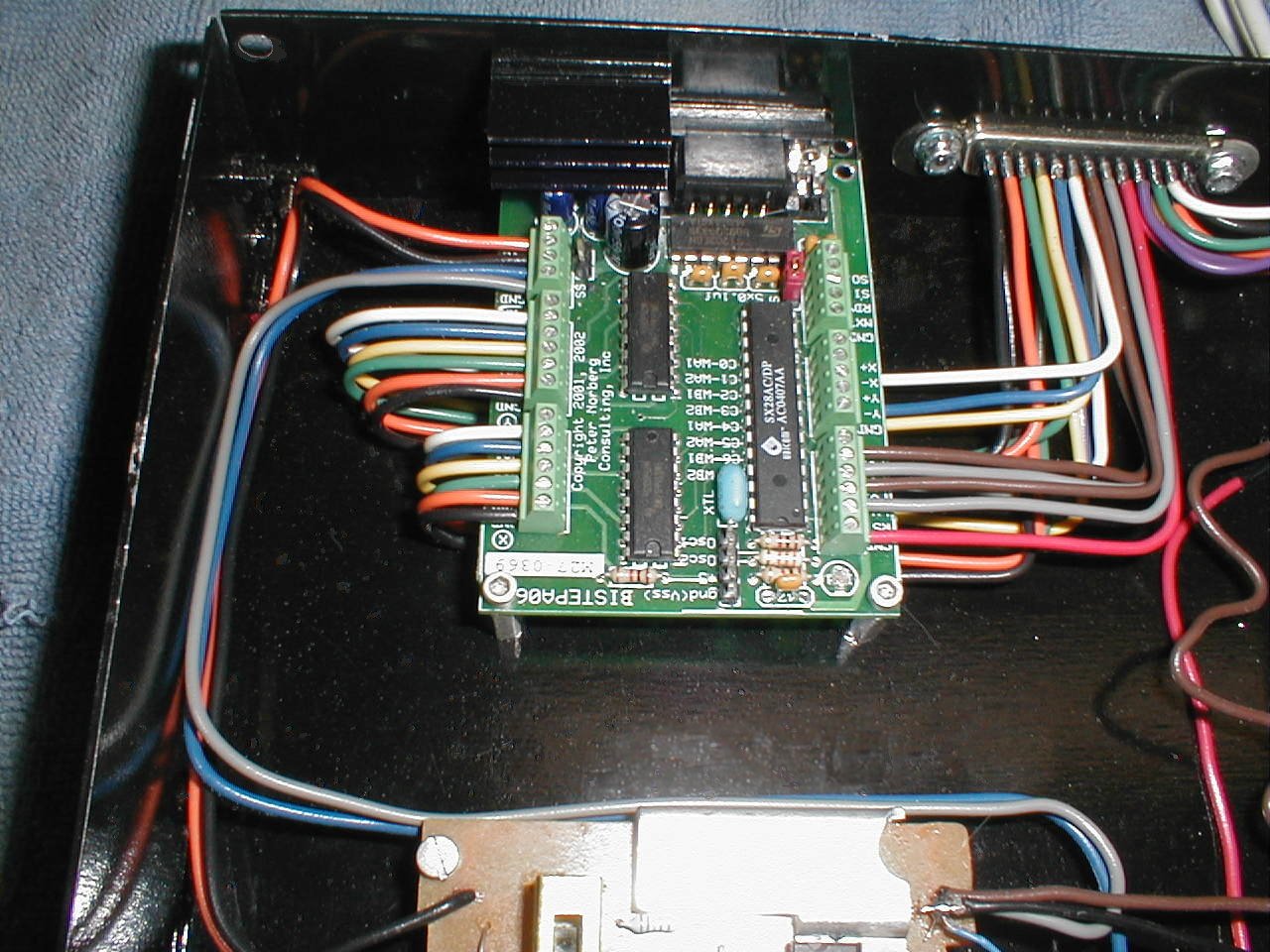

A closer view of the stepperboard Bi-Step A06 controller. You can

get the board with the screw terminals or pin-type connectors. I

chose the screw connectors. The wire is 12 gage solid

copper. There is not much voltage drop between the board and

tilt-pan assembly. |

|

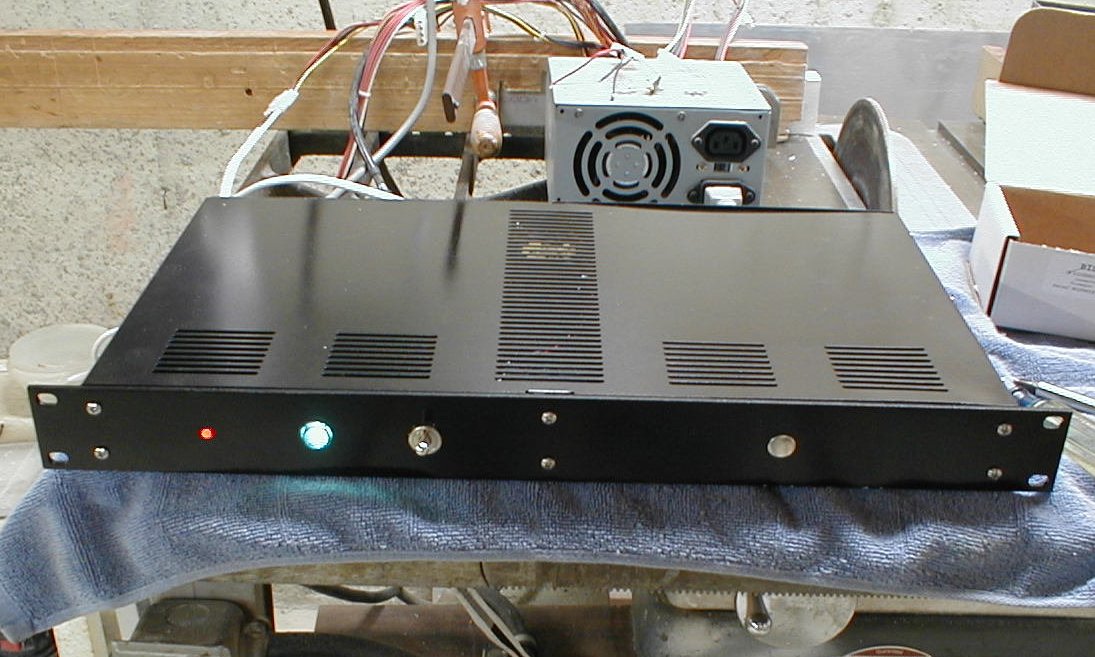

Here is a shot of testing the LEDs on the 1U case using an old AT type

power supply. I used my Rivergate Bulldog 30

amp power supply once I got everything mounted. The Bulldog

is way more powerful than needed, but fulfills the requirement of a

linear power supply that the stepperboard needs to operate

correctly. I eventually purchased a 6 amp linear supply to

dedicate to the camera so I could return the Bulldog to its place on

the test bench. The stepper motors only draw a couple amps total,

so the 6 amp supply doesn't have to work very hard to supply the motors. |

|

Between the 4U computer and the SCSI array, you should just be able to

make out the 1U stepper controller and preamplifier. Below the

rack cases are the old Linux boxes. The left one is the test box

with the software that controls the tilt-pan camera. The right

one is my connection to the web, file server and also runs software to

detect motion on the camera and save the movies without sound. |

|

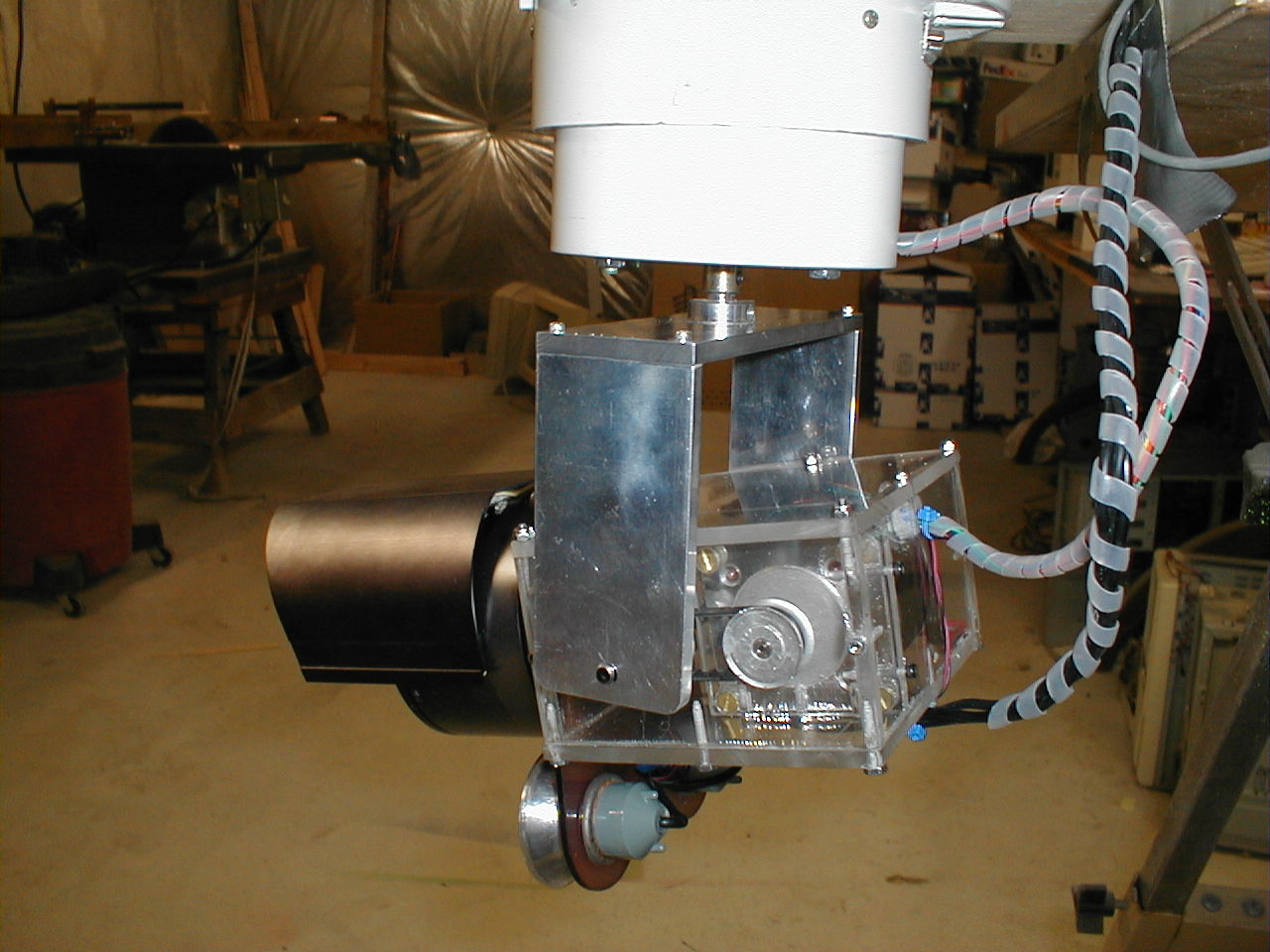

This is the last shot of the

camera and tilt-pan assembly before it got painted and moved

outside. You can see the microphone(s) under the camera. |

I actually finished

this camera a couple of months ago. Once I had it mounted

outside, I worked on a program to interface the tilt and pan functions

with the Motion

software. I also set up a web page where I can manually control

the camera by clicking on the side of the image that I want the camera

to move to. I also incorporated about a dozen "presets" so that I

can push a button and the camera will move to a pre-determined

location. I also added two buttons that control a sequence that

pans the camera slowly up and down the yard and driveway, then stops at

its home, which is the end of our driveway.

After playing with the

camera for a while, I decided that I didn't like the stepper

motors as much as I thought I would. Over the course of two

weeks, I designed and built another tilt and pan prototype using a

couple of very large 1/4 scale servos for controlling 1/4 scale radio

controlled airplanes. I am MUCH more impressed with the

performance of the servos than the steppers. The main reason is

weight. Steppers are heavy and the mass of the camera, housing,

bracket, and stepper adds up to a substantial amount. It takes a

bit of time to get all of that mass moving and it also take some time

to stop it. This make it hard to follow quick movements, like a

rabbit or squirrel running across the property. Once I changed

over to servo motors and built a tilt pan controller that was about 1/3

the weight of this project, I started to get much better tracking

ability. I am in the process of designing the third tilt-pan

assembly and am hopeful that this one will do everything that I need it

to do.

I have also had enough of

using the wrong tool for the job. Trying to use a drill press for

a milling machine is an exercise in frustration. After wanting

one for years and researching what to buy for months, I have purchased

a mill. As I write this, I am waiting for the trucking company to

call and let me know that they have my new toy. This should

finally allow me to build what I can draw.

|

|

|

|

|

|

|

|

© Fager 7-31-05