Tilt/Pan

Camera Mount

September 14, 2005

Getting Started

(I can't believe that I have been working on this project for a year. Besides the normal interruptions, I have had a couple of surgeries on my sinuses that slowed me down a bit.)

This project started back in August of

2004 when I got the urge to buy a video camera. I think I had

seen

some security cameras at Costco for about $1000 and thought that "I

could do that." As

I began researching cameras, I started thinking about my requirements

and what I would like to

do with the camera. Since our son, Michael, is about to start his

third year of college, Susie and I have the opportunity to do more

traveling. The idea of being able to keep track of our

house and property with a video camera on the web is something that

I've thought about for a long time.

Flash back to me being about age 10 and my folks

were looking at new homes. I was thoroughly amazed by the "then

new"

intercoms that were cropping up on the model homes of the 1960's

era.

Pretty neat stuff for the time. With the intercom, you could talk

to whomever was at the door, or talk to dad in the basement, or the

kids

in their rooms. You could even pipe music throughout the

house. Forget the fact that these houses were only about 2000

square feet and

you could probably talk loudly and be heard as easily. I was

impressed

at the technology none the less. From

that time on, my interest in home automation grew.

Over the years I have done a few intercoms, but nothing too

exciting.

Now I had gotten the home automation bug again and it was time to see

where this would lead me.

Looking for a camera was quite a

task.

The number of cameras on the market is staggering. You can spend

as

low as $25 and top $2000 quite easily without even venturing into the

professional end of the market. As this was my first

security

camera and I had little idea of where I wanted to take this project, I

limited my spending on my first camera to under $300 with the thoughts

that if this was something that I wanted to get serious about, I could

easily replace the camera. So far, twelve months into the

project, I

have

not felt a need to jump to the next level of camera - though I may be

getting close.

My

original camera requirements were just that the camera be able to watch

the front

of my home - from the street to the front door. This meant

getting a security camera with

a

tilt/pan/zoom (PTZ) assembly. PTZ can be performed from a

dedicated controller or through the computer. The computer was

the obvious choice for me. Having the camera and PTZ computer

interface would allow me to be able to view and control

the camera's view from the Internet. This would be nice for

checking out the house while on trips. As I continued

to research suitable cameras, I found that the ability to "see at

night"

was well within my price range, but that a weatherproof tilt/pan/zoom

was

going to be the costly part of the equation.

After finding a camera that allowed

viewing

color by day and black and white with infrared assist at night, (the

104 LED color camera), I decided that rather than buy a tilt and

pan device, I would try my hand at building one. We'll get back

to this a little later. The camera I purchased is a pretty fair

quality

unit with a 25 mm fixed lens. To put this lens in perspective, a

6 mm lens is supposed to be about what your eyes would see, so 25 mm is

a close-up or telephoto lens. (They have a

pretty good

example

of different lens options and the field of view from each here.)

Since this is a fixed lens, the zoom "requirement" was something I

wouldn't have to

deal

with on this camera, but at some point, I would like to either buy or

make one.

Image Sensors

The cameras I looked at used either a

CCD (Charge-Coupled Device) or CMOS (Complimentary Metal Oxide

Semiconductor) image sensors. There was a time in the not to

distant

past when the CCD image sensor was the sensor of choice. Now,

both the CCD and

the CMOS chips are found in quality cameras, with the CMOS chip being

used in cameras such as the $5000 Nikon D2X. In the security camera

market, there seems to be more of the CCD chipped cameras in the mid to

high quality range, though the CMOS cameras are getting better and are

less costly to produce. This is mainly due to the fact that the

CMOS sensors can be manufactured in the same "fabs" (chip fabricating

facilities) as for other integrated circuits, like memory. The

CCD sensors use a totally different manufacturing process not shared by

ICs.

The cameras I looked at used either a

CCD (Charge-Coupled Device) or CMOS (Complimentary Metal Oxide

Semiconductor) image sensors. There was a time in the not to

distant

past when the CCD image sensor was the sensor of choice. Now,

both the CCD and

the CMOS chips are found in quality cameras, with the CMOS chip being

used in cameras such as the $5000 Nikon D2X. In the security camera

market, there seems to be more of the CCD chipped cameras in the mid to

high quality range, though the CMOS cameras are getting better and are

less costly to produce. This is mainly due to the fact that the

CMOS sensors can be manufactured in the same "fabs" (chip fabricating

facilities) as for other integrated circuits, like memory. The

CCD sensors use a totally different manufacturing process not shared by

ICs.

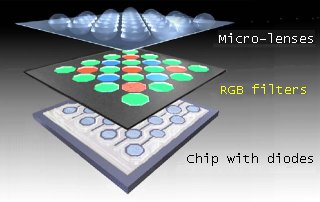

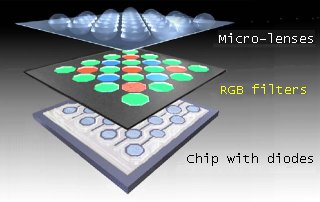

The Sony Super HAD

(Hole-Accumulation Diode) CCD that comes with the camera I purchased is

an improvement on previous on-chip microlens designs found in many

security type cameras. The on-chip

microlens has one lens for each of the diodes (also called photosites)

that change light into electrons. Sony has been able to reduce

the amount of "wasted" light by changing the lens shape and

reducing the distance between the lenses. More information on the

Super HAD CCD may be found here.

Sony now offers what they call the EXview series of HAD CCD chip with

enhanced infrared (IR) capabilities.

IR and the ability to see in darkness

has

always been fascinating to me. The ability to see when

it is dark is definitely an advantage when thinking about home

security. The image sensors

start by

converting light into electrons at the photosites on the sensor. With

the addition of red, green, and blue filters (additive color system) or

cyan, magenta, and yellow filters (subtractive color) for each of the

photosites, they are able to produce color images. However, being

able to produce color images has it's cost. The filters cut down

on the available light that hits the

photosite so that a color camera has less sensitivity than a black and

white camera using the same image sensor. In addition,

because a color camera must dedicate photosites for each of the three

colors used to produce a single pixel in the image, the resolution of a

color camera is less than that of a black and white camera using

the same image sensor.

Throwing "night vision" into the mix is

easy. Unfiltered photosites (black and white image sensors) are

not only sensitive to the range of visible light, but are also

sensitive to the near infrared range. Some chips are better than

others for this and the day night camera I purchased is happy to

produce images using light in the 940 nanometer range. In case

you've forgotten your electromagnetic wavelengths, they are

(approximately): below 400 nm = ultraviolet, 470 nm = blue,

570 nm = yellow, 670 nm = red, above 700 nm =

infrared. The low 700s range of infrared is still somewhat

visible as a dull red glow, but 940 is completely invisible to the

human eye. With the 104 LEDs producing infrared energy, the

camera

has a night time range up to about 60 feet (~20 m) with pretty good

brightness and tails off from there. While testing how well the

camera picks up IR light, I purchased a couple of

high intensity, infrared LEDs from Radio Shack and wired them into a 2

cell flashlight. It produces a nice little beam that can be seen

by the camera, but not by me or passers-by. I'm sure the

neighbors think I'm nuts when I'm out in the street, in the camera's

view, playing with what looks

like a non-working flashlight. Maybe this just confirms my "nuts"

status.

Anyway, I am having fun playing with

IR. I have recently purchased 500 IR LEDs and have some ideas for

wiring

these up beside some low voltage outdoor garden lamps. If this

project works as expected, I will be able to run the visible light if

guests are coming over or we will be returning home late. Once

it's

time to secure up the house, I'll be able to shut off the visible light

and crank up the IR and let the camera watch the property as I

sleep. This sounds like a good plan, but I'm getting ahead of

myself and need to get the

tilt and pan built first.

There are two accepted ways to approach

moving

the camera on a tilt/pan assembly. The first is using

servo

motors. Servo motors work by placing an encoder

in line with the motor output shaft. This way, there is a known

encoder position

for every location the motor can turn to. It is possible to accurately

move the motor to the same location time after time. Servos are

common

in the radio control modeling world and because of this, there are many

moderate cost controllers and servos available. A standard servo,

similar to

the Futaba

S3003 can be had for about $US10. The down-side as far

as

my application was concerned was I *knew* them and wanted to learn

about stepper motors. So, even

though I

am much more

familiar with servo motors, I ended up using stepper motors. As

it turned out, I did learn quite a bit about steppers and found out

first-hand the positive and negative aspects of using stepper motor

systems..

Stepper motors are permanent magnetic

motors that "step" or move one increment each time the controller gives

the motor one pulse. They don't require position feedback if run within

their limits. When stopped, they inherently hold their position.

This "holding their position without power" mode is usually called the

"detent hold" or detent holding ability. The magnetic field of the permanent magnets

hold the

motor in position when the power is removed from the coils. The

force that is needed to overcome the magnetic field can be surprisingly

strong. This detent torque will be quite useful in the holding

the view angle when using the tilt function of the setup.

Once you power up the controller, each

pulse of the controller sends current to the individual coils

of the motor.

By turning on and off the individual magnetic fields in a sequential

pattern, the motor turns. There is a good explanation of the

different stepping sequences here.

There are many ways of controlling stepper motors through a

computer. You can use a

software program to apply power through the parallel port to move

bipolar

and unipolar steppers. You may also program the stepping

sequences

into an electronic logic circuit and use switches, or the serial or USB

ports to

control the

stepper(s).

To start my learning about stepper

motors,

I dug through the "old parts" boxes in the basement workshop and came

up with a

couple of 5 1/4" floppy drives. I salvaged the steppers

from

these and played around with parallel programming for a couple weeks

until

I came to the conclusion that this wasn't the interface I was looking

for.

While I was researching different ways to control the steppers, I ran

across

a program that would focus my expectations of this project. The

program is called Motion. It is an open source project designed

to

detect motion from cameras. If you are interested, you can

read

all about Motion on the Motion

Twiki. I will be revisiting Motion once the hardware is

built,

but for now,

Motion

has some support for a serial and USB tilt and pan interface. In fact,

they have a schematic for a one axis pan controller.

After

some thoughts of building my own circuit for a serial interface, I

decided on a pre-built controller board from Stepperboard.com.

Stepperboard's BiStepA06

was the board that suited my project the best.

I ordered one and received the BiStepA06 a few days. I

mounted it

in a small project box with a circuit to drop the 12+ volts from my

power supply down to 9 for the logic circuit of the stepperboard and a

couple LEDs.

The BiStepA06's circuitry then drops it to 5 volts. The motor

circuits run on the

full 12+ volts from the power supply. I also added a small fan to

keep the chips from getting too hot. I spent the next week

playing with C programming and serial ports until I had a basic program

to allow my Linux box to talk to the stepperboard. This time was

pretty uneventful until the stepperboard stopped working one day.

An email or two later, I packed up the board and shipped it back to the

manufacturer. It turned out that I may have killed it by static

discharge (but I don't think so). However, Peter replaced the bad

parts and shipped the repaired board back quickly and for just the cost

of quick shipping that I requested. I was pleased with the

treatment I received and would not hesitate to recommend the product.

So with the board back

and the basic

program for controlling the

steppers written, it was time to order the mechanicals that would make

up the tilt and pan device. I went to Jameco for the stepper

motors and purchased a pair of 6000 gram-cm holding torque 12 volt

steppers. These are a bit on the "overkill" side, but having more

power than I need is preferable to going the other way. I also

hit Stock Drive

Components for some timing pulleys, shafts, belts,

thrust washers, collars and flanges. These were quite expensive

for what they were and I had some issues with their ordering software

while trying to place my order. Finally, to end my dealings with

them, the order was late in arriving

and when

it arrived, it was packed extremely well in heavy cardboard with wooden

ends, with not a bit of damage on the outside of the box, but the 1/4"

diameter steel shaft that I ordered was bent. This meant it

had to be bent when

they packed it. After spending almost $100 in parts, I expected

better treatment. While Stock Drive is one of the largest

companys for gears,

pulleys, and other miniature drive components, I think I will try to

look elsewhere next time I need to order.

The last order I placed was for some

ball bearings to ease the friction

a bit in the tilt housing. I ended up getting these at Tower Hobbies

and purchased 10

for the price of 2 at Stock Drive. These 1/4" by 3/8" flanged

bearings happen to be the same as used on a couple of radio control

cars I own, so I was familiar with the part and knew that Tower would

have a fair price for them.

The last item on the list was what to make

the assembly out of. I gave this a lot of thought and finally

decided on acrylic plastic for the tilt housing and wood and plumbing

supplies for the base and pan housing. Yes, I admit that it is a

strange combination, but that's me. I had

considered making the whole project from aluminum, but it would have

made for a lot more work under the drill press. Aluminum would be

nice if I decided to

make more of them, as I would have the housings cast and

machined. However

casting a one-off piece is expensive if you don't have the equipment to

do it yourself.

Prior to ordering my parts, I spent the better part of 2 weeks working

on the cad drawings for the

tilt assembly and a couple of days on the pan assembly. I had

been designing the tilt and pan device in my head for about a month now

and it was time to get the design on paper and work out the bugs.

I encountered some items

that needed consideration while

designing the tilt mechanism. First, the tilt housing with camera

attached had to balance with a camera that mounted from the rear rather

than the bottom like a normal camera. This is why I went with a

timing belt rather than direct drive. The timing belt allowed the

motor to be placed in the rear with the camera in front. The gear

ratio is still 1:1.

Secondly, the direction of rotation had to be accounted for so that

panning to the right and tilting upward were the same direction.

I first drew the plans backward and only through visualizing the

assembly in operation did I realize that I had the motor flipped the

wrong way to tilt up with a counter-clockwise rotation (when looking at

the front of the motor.) Yes, you can wire it backwards to make

it turn the opposite direction, but it's better to have it right to

begin with.

I made

templates for all of the acrylic pieces I needed and proceeded to cut,

drill, and tap each of the pieces. I have put together a pictorial of

the build process here. I have

tried to put it in some kind of logical order for viewing as the order

I built it in was often dictated by which one of the sub-projects I was

interested in on that particular day. It wasn't unusual for me to

work on a couple of different parts on the same evening. When I

was doing the drilling and tapping, I would have to take a break and

work on something that was more fun, then go back to drilling holes and

cutting threads. The holes had to be drilled as accurately as I

could get them, given the accuracy of my drill press. If a hole was off

by more than a couple hundredths of an inch, the piece would often have

to be scrapped. I ended up scrapping more than I would have liked

to. This usually happened when I got tired of drilling holes, so

I started drilling and tapping some holes in the beginning of the

evening and then moving on to another piece of the project after an

hour or so.

I had an empty 1U rack case that I

decided to use to hold the controller. As I was wiring up the

Stepperboard, I started thinking about

sound for the camera. My camera isn't equipped with a microphone,

much less stereo mics,

but I was thinking that it wouldn't be too hard to implement. I

was wrong.

© Fager

7-30-05

The cameras I looked at used either a

CCD (Charge-Coupled Device) or CMOS (Complimentary Metal Oxide

Semiconductor) image sensors. There was a time in the not to

distant

past when the CCD image sensor was the sensor of choice. Now,

both the CCD and

the CMOS chips are found in quality cameras, with the CMOS chip being

used in cameras such as the $5000 Nikon D2X. In the security camera

market, there seems to be more of the CCD chipped cameras in the mid to

high quality range, though the CMOS cameras are getting better and are

less costly to produce. This is mainly due to the fact that the

CMOS sensors can be manufactured in the same "fabs" (chip fabricating

facilities) as for other integrated circuits, like memory. The

CCD sensors use a totally different manufacturing process not shared by

ICs.

The cameras I looked at used either a

CCD (Charge-Coupled Device) or CMOS (Complimentary Metal Oxide

Semiconductor) image sensors. There was a time in the not to

distant

past when the CCD image sensor was the sensor of choice. Now,

both the CCD and

the CMOS chips are found in quality cameras, with the CMOS chip being

used in cameras such as the $5000 Nikon D2X. In the security camera

market, there seems to be more of the CCD chipped cameras in the mid to

high quality range, though the CMOS cameras are getting better and are

less costly to produce. This is mainly due to the fact that the

CMOS sensors can be manufactured in the same "fabs" (chip fabricating

facilities) as for other integrated circuits, like memory. The

CCD sensors use a totally different manufacturing process not shared by

ICs.