|

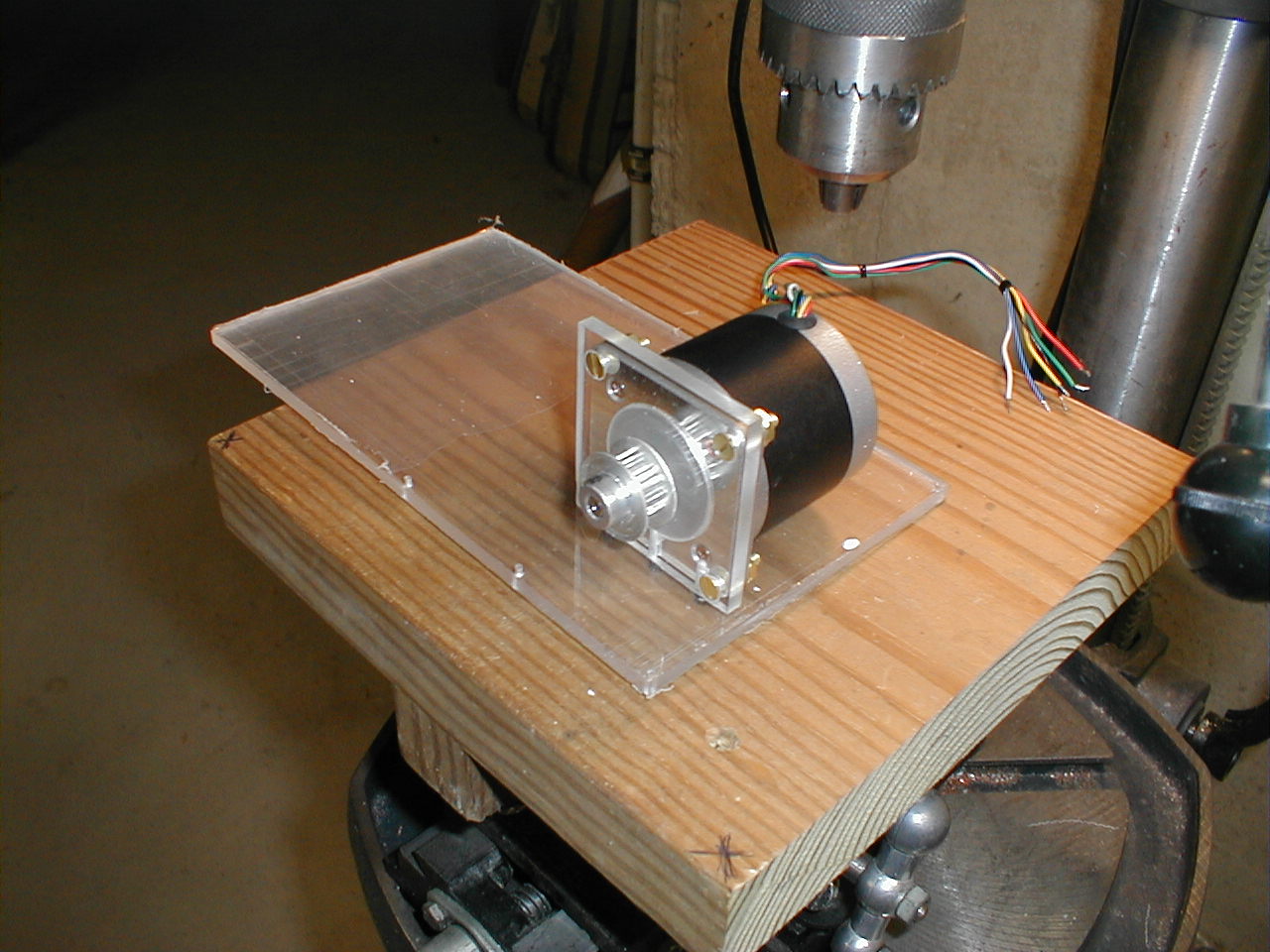

After

laying out the parts in AutoCad, cutting the patterns, and transferring

the patterns to the acrylic, I began cutting and milling the

parts. The first of the tricky cuts was the stepper motor

mount. "Tricky" is relative, but trying to mill on a drill press

is tricky!

To get the recessed circle routed out of the acrylic, I used a shaft

that was the same size as the hole in the center of the mount and

rotated the part around the shaft. The second piece of acrylic

below the motor mount was rotated along with the mount to prevent

scratches on the bottom of the motor mount. This piece turned out

almost perfect with the raised step on the stepper motor fitting snugly

into the recess on the mount.

|

|

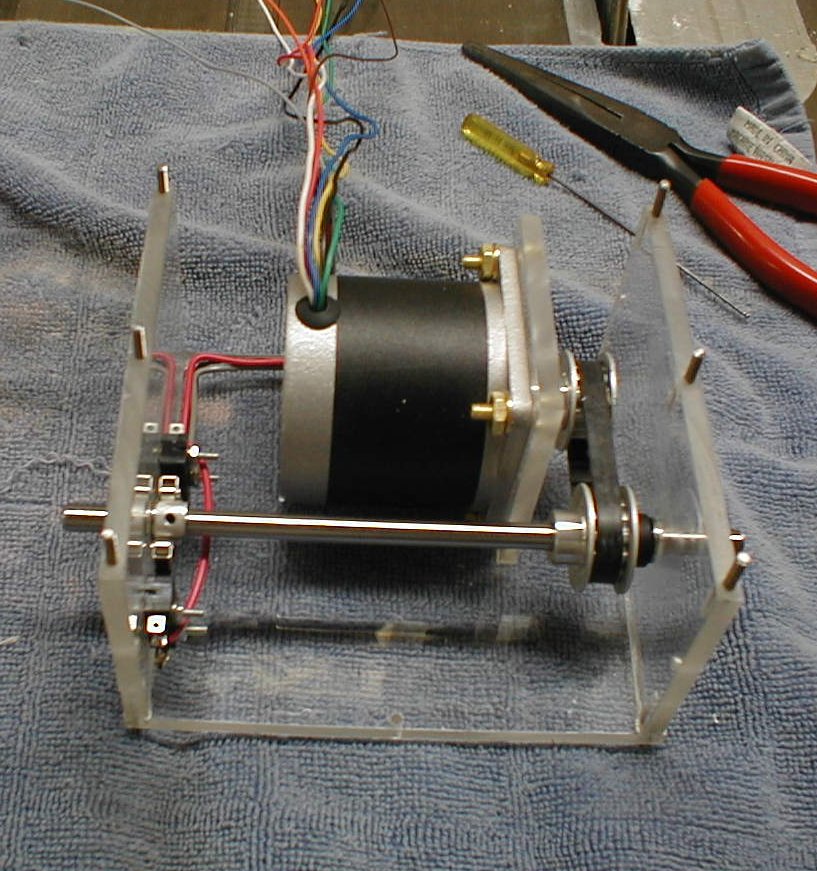

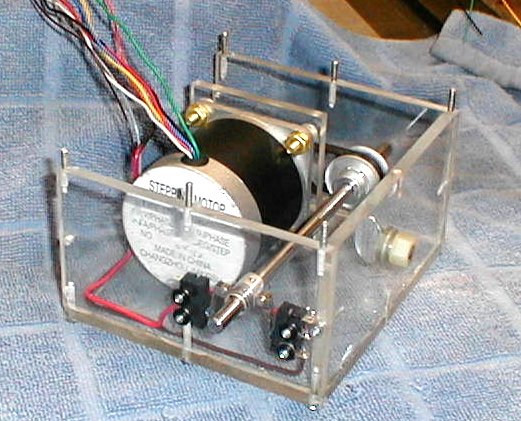

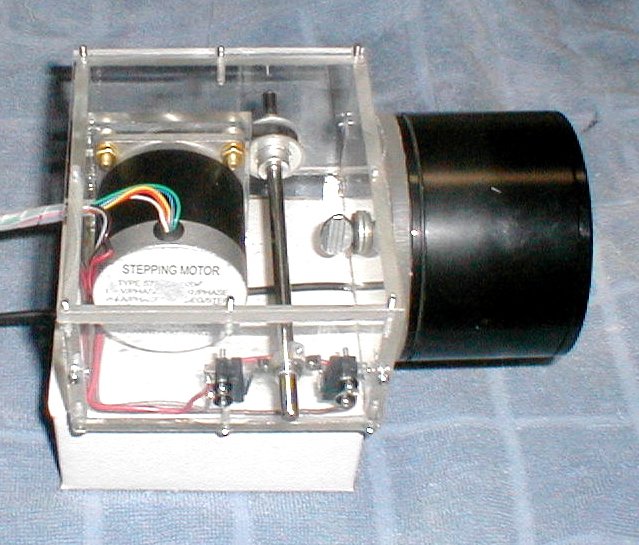

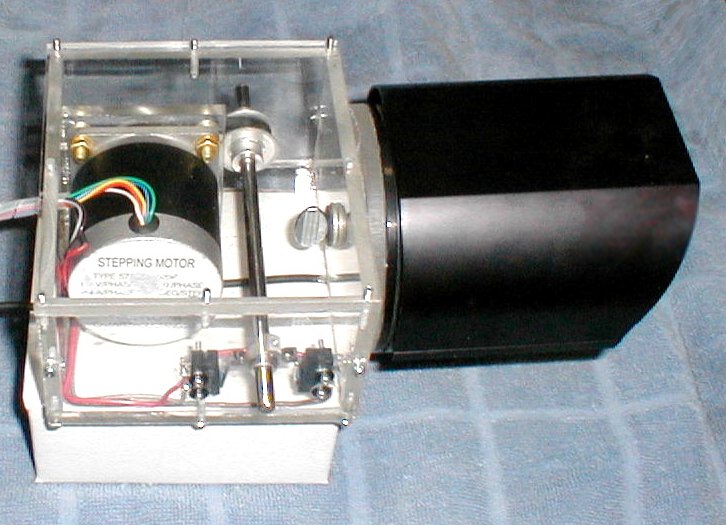

Here,

the motor is attached to the mount and the mount is attached to the

base of the tilting camera mount. While it looks like the base of

the camera housing is way too wide, the piece will be cut after the

left-most of the three holes in the front of the base.

I assembled each new piece as soon as it was finished not only to make

sure that the parts fit, but also to admire my work. ;-)

This was a fun project to build and I was in no rush to finish it.

|

|

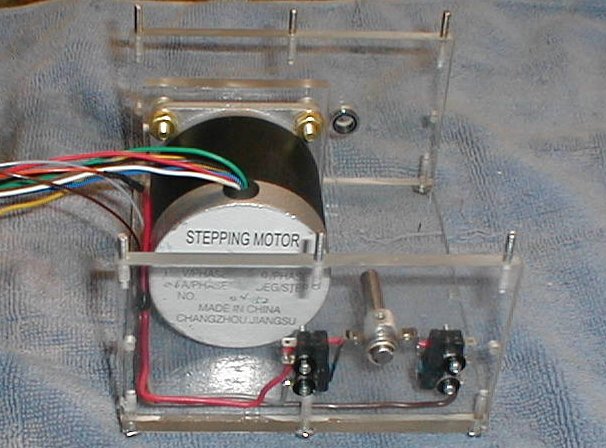

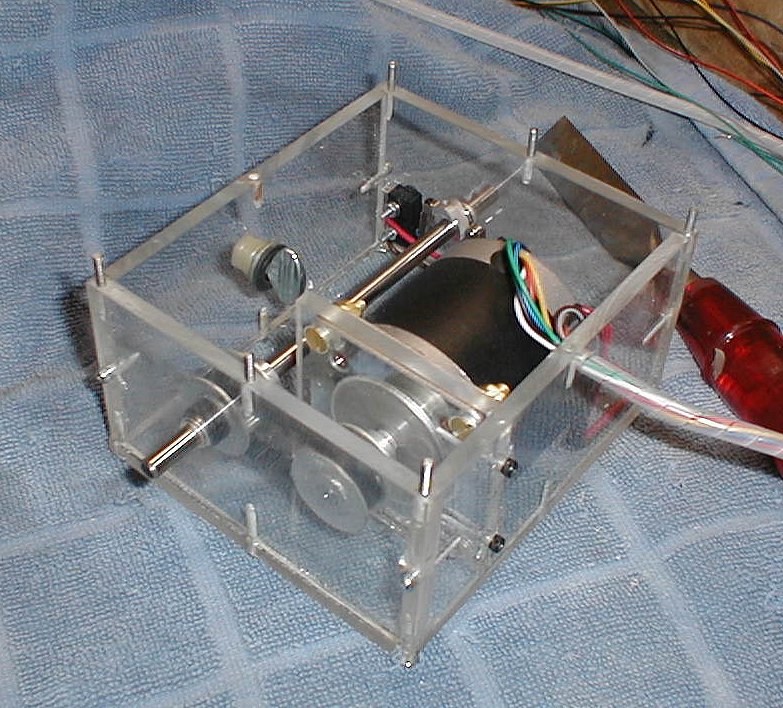

Four

pieces done. The1/4" by 3/8"

flanged

bearings are visible in both end pieces.

In the foreground of the picture, you can see a stub of an axle with a

hand ground cam lobe that actuates the roller equipped

micro-switches. These switches are adjustable with a total of

about 1/4" of travel. They are used to limit the amount of total

tilt that the camera will be allowed to move.

The cam lobe is also adjustable by means of a set screw in the center

of the lobe. The hole is smaller in diameter than the roller on

the micro-switch, so the roller glides right over the hole. I

must have spent a half hour envisioning how the unit would tilt before

I was sure that the switches were wired correctly.

|

|

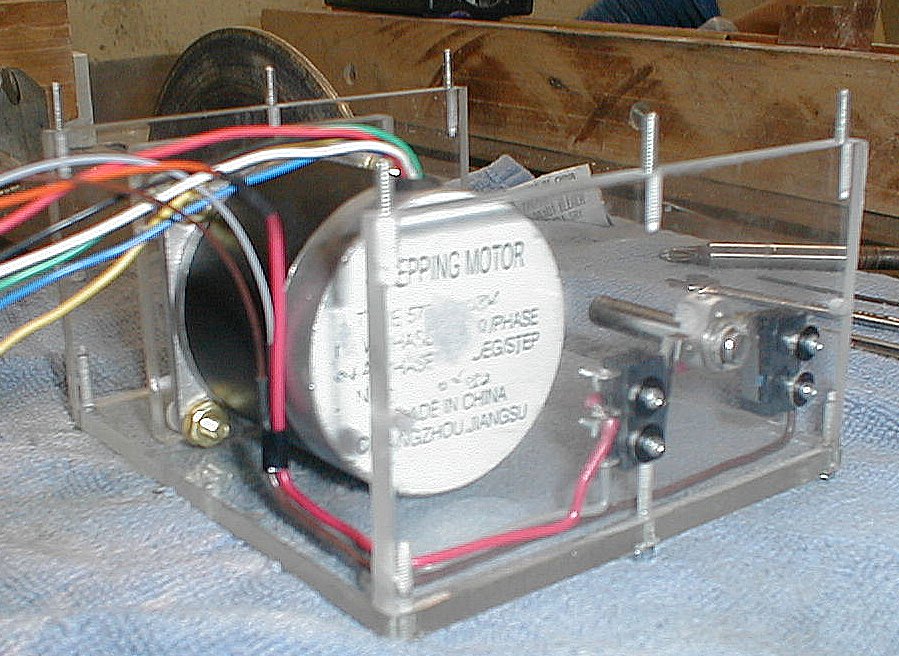

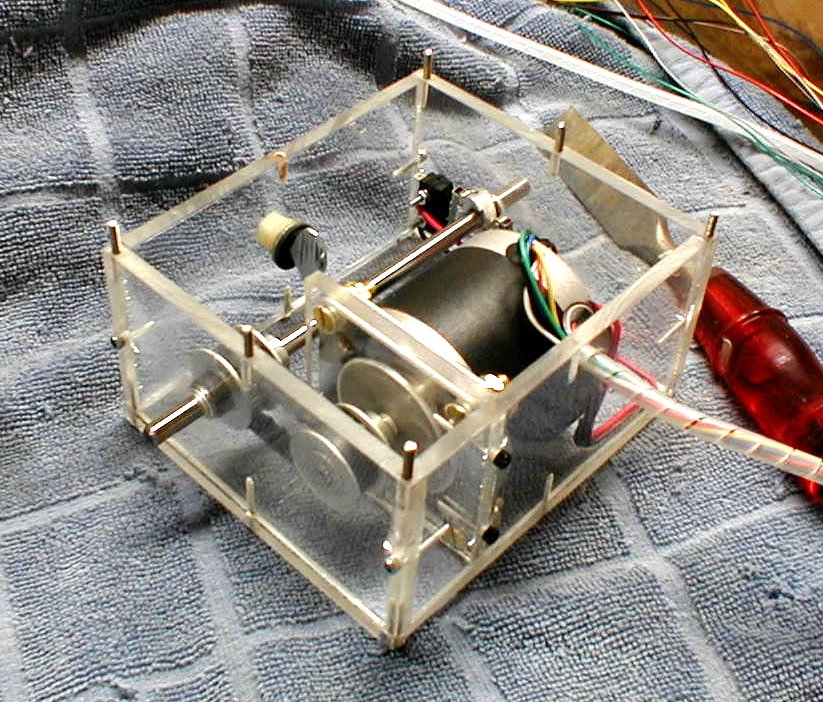

Another

shot of the cam lobe and micro-switches. The height of the cam

lobe is easier to see in this shot.

The black washers are rubber coated to seal the oval adjustment holes

for the switches. The bearings also have plastic seals and I

packed the bearings with silicone grease to make sure that water could

not enter the housing.

Even though the camera will be placed under the eaves of the house, we

get violent storms in the summer and horizontal rain is not that

uncommon. Hopefully I will get a year or so of service from the

tilt and pan mount before it will need to have the bearings repacked

with silicone grease.

|

|

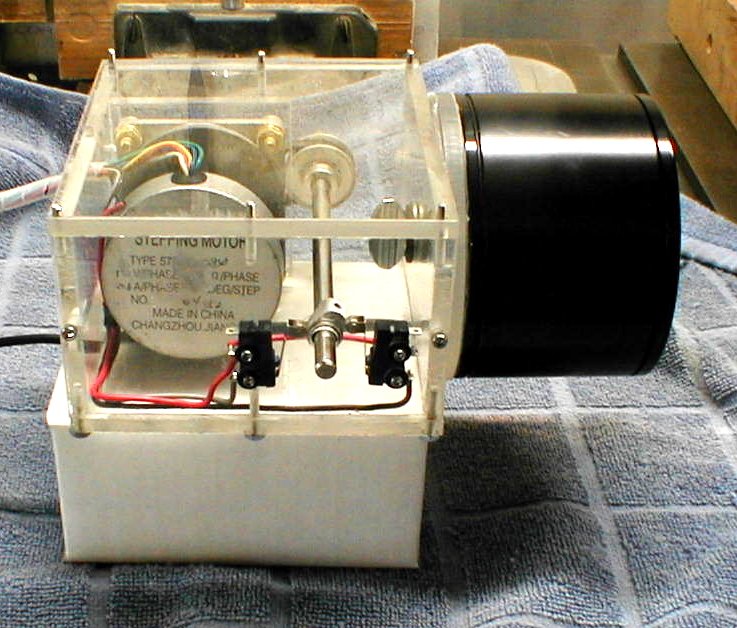

The

first critical test of my measuring, cutting and drilling came when I

installed the pulleys and toothed belt. I ended up with

deflection of between an eighth to a quarter of an inch. Perfect.

It pays to, as the saying goes, measure twice and cut once.

If there had been a problem with the belt being too tight or too loose,

I would have just needed to recut the bottom plate. Not too time

consuming, but nice that it fit right the first time.

At this point in the assembly, with the motor offset quite a way from

the axel shaft, it seems hardly possible that I have calculated the

weights properly so that the camera and housing will balance perfectly

on the axel, but I will have to trust that my calculations are correct

as I won't be able to check it until the camera is mounted.

At least I know that the distance between the motor and shaft was

right, so the chances that the rest of the equation will work is on

track.

|

|

The

front plate of the tilt housing is mounted. The camera is mounted

a bit below the center of the plate, on the same plane as the motor and

axel shafts.

While the stepper motor sits flush with the floor of the housing, there

is about 3/8" of space above it, between the top of the motor and the

bottom of the top housing plate. This is to allow for the wires

coming out of the stepper motor.

I haven't mentioned it, but the lateral play in the axel shaft is

adjusted with axel shims from an Associated RC-10 radio controled

car. Both the pulley and cam lobe for the limit switches have set

screws to hold them securely and the shims go between the pulley / lobe

and bearing. The bearings are flanged with the flange to the

inside.

|

|

The

rear plate gets attached. The hole at the top for the 6 motor

wires, 3 limit wires, and eventually another 3 microphone wires in a

shielded cable and the composite camera power and video feed wires will

all come from the rear of the camera housing and terminate in the box

that will hold the pan assembly.

The chisel with the red plastic handle is about 40 years old. It

was one of my dad's tools and now a cherished one of mine. It still

holds a great edge after decades of being honed on an oil stone and

deburred on a leather strap. It is also a great tool for shaving

small bits of plastic to make sure that the plates filt together

perfectly.

Once the entire tilt housing has been assembled and checked for fit, it

will be sealed with a special acrylic adhesive that is as thin as water

and applied with a syringe with a fine needle. The adhesive will

|

|

be

"wicked" up between the joints similar to a "sweat joint" when

soldering plumbing. I didn't have a lot of experience with this,

so I used many of the scraps of acrylic that I accumulated to

practice. This adhesive is really thin! It also leaves

visible traces of itself any place it comes in contact with. The

adhesive works by softening up the acrylic and needs perfectly mated

joints and some pressure to work.

I'm glad that I took the time to do some research on "gluing acrylic"

before I tried it, as I am sure that I would have ruined the parts if I

hadn't practiced first.

You can find a lot of information on working with acrylics by searching

for acrylic diy build aquarium.

|

|

Finally

I get to put the top plate and the camera on to check for

fit. It fits pretty well.

The round plate behind the camera is there to give me some additional

weight in the front to help balance the tilt housing and camera.

I have figured the balance point almost perfectly. With the plate

in place, it is a little heavy on the camera end. If I remove the

plate, it changes to be a little heavy toward the rear. Once I

mount the microphone plate, I won't need the acrylic disk and the

balance should be close enough that the force of the permanent magnets

in the stepper motor will hold the camera and tilt housing at whatever

angle I need.

The thumb screw that holds the camera in place will allow me to make

sure that the camera is positioned properly and then cinch it down.

|

|

Tonight

I hooked the camera up to the A06 controller and ran through a few

commands to make sure that the limit switches were doing their job

properly. I had to adjust them both a little to get them to allow

the desired 135° of movement.

The camera will be mounted under the eaves of the second story of our

home, above the front door. I would like for the camera to be

able to look straight down so that I can see who is at the door.

The upward angle should be enough to see over the tree in the front

yard and on to the horizon beyond and the line of trees that is at the

end of its line of sight. That should be handy for seeing weather

related information such as the trees swaying or rain and snow hitting

the leaves or branches.

In the summer, I will be able to view the driveway and sidewalk, but a

lot of the front yard will be obscured by the large flowering plum

tree. In the

|

|

winter,

I should be able to view almost the entire front yard due to the leaves

being gone from the tree.

The sun shade is test fit on the camera. It is made from a light

weight plastic extrusion and doesn't add much weight to the setup.

This evening I spent about an hour and glued up the tilt housing.

It went pretty well with just a couple of places where the acrylic

adhesive got on places where I didn't want it. I buffed these out

the best I could and unless you are really looking for them, you

wouldn't see them.

Time to move on to the pan assembly.

|