|

While we were

discussing what to do with my son's Ram truck with a case of the

death

wobbles, he had another car problem. His wife's recently

purchased, used, 2012 Jeep Wrangler Sport Unlimited 4 Door

started smoking from under the hood. My son, Mike, was able to

determine that it was the air conditioning compressor clutch

producing the smoke and shut off the AC. The rubber ring in the

clutch disk assembly had gotten so hot that it was smoldering.

It didn't catch fire, but I have since read of instances where

people said that theirs did. He sent me some pictures, but

they weren't too clear due to the compressor being hidden

beneath the top radiator hose.

He gave me a call and

we talked about the possibilities. I suggested that if the

compressor wasn't locked up, he might be able to just replace

the compressor clutch. He made some calls and later told me that

the dealer wanted over $800 parts and labor to replace the

compressor. The compressor alone was $510. Apparently, the

compressor clutch assembly doesn't come separately. I told him I

would look into it and see what we could do to drop the price a

bit. There's not a lot of info on this particular air

conditioning, but I read as much as I could find. There are a

half dozen sites that advertise that they carry a replacement

compressor that will fit the 2012 Jeep. There are also a few

Ebay sellers that list a replacement, but no one I found sells

just the compressor clutch.

I found a seller on

Ebay that had a compressor they said would work. Since they had

good reviews, I sent them an email with the Jeep's vehicle

identification number (VIN)

and asked if their compressor was a drop-in replacement. They

said yes and I ordered it. At just under $200 with shipping

included it seemed to be one of the better deals I had found. I

got the compressor quickly, it was a brand new Chinese made

compressor and it looked good. If it fit, we were in business.

We put it aside until we were ready to replace it.

With the Dodge's death

wobbles cured, the day finally came to install the compressor on

the Jeep. We pulled enough parts off the Jeep to actually be

able to see the AC compressor clearly. This involved draining

the engine coolant and removing the top radiator hose and

radiator overflow tank to gain some access to the compressor. I

got a better look at the compressor and noticed that we had some

issues. The electrical plug on the new compressor didn't match

the one in the Jeep. This was easy enough to fix, but the next

problem wasn't. The AC high and low pressure hoses have formed

aluminum connectors where they attach to the compressor. These

are formed in a manner that allows them to be installed in one

direction only. Each port on the compressor has a stud that

aligns the hose connector to the port. The studs on the

replacement compressor were in different positions than the ones

on the original. If you look at the picture above and the

picture of the replacement compressor below, you'll see that the

position of the studs on the original compressor don't match the

position of the stud holes on the replacement. I suppose that if

you really wanted to use the replacement, you could replace the

hoses, but that's a whole different can of worms. We'd need to

get hoses made up and I'd need to either hard wire the

compressor or cut out the waterproof socket on the old

compressor to replace the new one that didn't match. I might be

up for this on a 10 year old vehicle, but not on their

relatively new Jeep that was just out of its warranty. I decided

that I needed more info on the compressor so I could try and

match it to a replacement. I got out an inspection mirror to see

if I could find the part number for the compressor. Here is the

info from the sticker I found underneath the compressor.

| Compressor

label -- the compressor number is 55111374AB |

As a last ditch effort, we measured the

clutch disk on the new compressor to see if we could swap it

with the old one. Unfortunately, both the size of the disk and

the splined mounting were different from the stock one. We

put the Jeep back together and Mike made the long trip back

home. Aside from getting to visit with my son, it was a wasted

day. I'd contact the Ebay seller and see what we could do to get

the proper compressor.

Having worked on a

lot of vehicle air conditioning systems, I was curious about

the change in compressor clutch design from when I was working

on them. All of the AC clutches I had ever seen worked the

same way. You flip the control on the dash to turn on the AC

and it energizes a coil on the compressor. The coil is an

electro-magnet. The magnetic force pulls the clutch plate,

which is attached to the compressor shaft with springs.

The clutch plate sticks to a machined area on the compressor

pulley. With the pulley and compressor shaft locked together

by magnetism, the compressor shaft is able to be turned by an

engine belt. The difference was that the old AC clutches used

three flat steel springs and this clutch used a ring shaped

piece of rubber as a spring. I am not sure why the change was

made, but my 2006 Dodge Ram also

has the rubber spring clutch. Most likely, it was a cost

cutting measure.

From the owner's

point of view, the change isn't a good one. With the old

system of metal springs, if the compressor clutch slipped, the

resulting wear would widen the gap between the clutch disk and

the pulley/clutch coil. If the gap got too wide, this would

prevent the clutch from engaging and you'd have no AC. To fix

it, you could reset the air gap between the clutch and pulley

by removing some shims from between the clutch hub and

compressor shaft. If you found ridges (signs of wear) on the

clutch plate, these could be dressed with a file to flatten

them out and you were back on the road with a working air

conditioner. With the rubber spring clutch, as soon as the

clutch starts slipping, the high temperatures (I read 1200° F

was possible in less than a minute of slipping.) could char

the rubber and make it detach from between the clutch hub and

clutch plate. Just like the one we were dealing with. Unless

someone can offer me some reasons otherwise, I think this is a

poor design choice. Especially considering that the dealer

doesn't even sell the clutch disk separately. You need to

replace a $510 compressor for what should be a less than $50

clutch disk. It's this kind of stuff that makes me glad that I

got out of automotive service field in the 90s.

I exchanged email

with the Ebay seller, BLA Autoparts, and they said they

couldn't match up the compressor number, but would issue me a

pick-up slip so I could return the compressor for a refund. I

got the refund and would work with this seller again. Next

time, it would be wise for me to send the compressor number

rather than the VIN.

I did some more

looking on the web and found that most all of the companies

who advertised that they had a compressor for a 2012 Jeep JK

used the same picture as the one we had purchased. No sense in

even contacting them. I did find what appeared to be the

correct compressor for $485, but that would be the last

resort. I was now thinking that I would try to repair the

clutch disk assembly.

|

|

|

|

|

My first idea was to

clean out the old rubber and pour some new rubber in its

place. There is a company named Smooth-On that sells all

manner of rubbers and plastics and I have used their products

to mold various parts when I was racing radio controlled cars.

The first problem with this is that I would need to make a

guess at the hardness and elasticity of the rubber. After some

research, I was guessing that I needed a Shore A hardness of

between 65 to 80. However, the more I thought about casting a

new rubber ring, the less I liked the idea. My biggest fear

was that the rubber would either shear on first use or be so

hard that the rubber wouldn't stretch enough to engage the

clutch. There were just too many unknowns for me to get it

right on the first attempt.

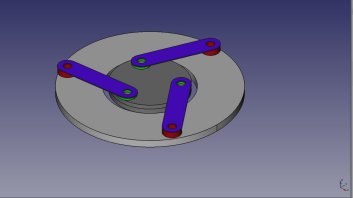

The more I pondered

the situation, the more I thought that modifying the clutch to

operate like the ones on older cars would be the best way to

go. The actual design of the clutch would be pretty simple.

There were three rivets in both the hub and the clutch plate

and the design called for three flat springs. Nothing to do

here except to get the old rivets out, remove the parts used

for the rubber ring and install my three springs. Since I have

a small lathe and milling machine, doing the modifications

would be straight forward. The big unknown would be how thick

the springs should be. They would need to be flexible enough

to allow the clutch plate to be pulled into the pulley when

the AC was on and still have enough tension to be able

to return the clutch plate to the disengaged position with the

AC turned off or when it was cycling.

|

|

|

|

|

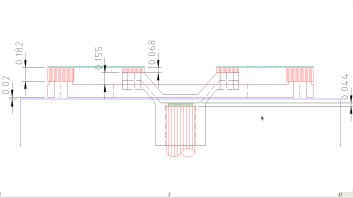

I spent a day working up the design using a couple CAD programs. I ran my ideas past my engineer friend, Scott, who provided some help and some confirmation that what I was attempting was the best plan of action given the circumstances. Some of the design considerations I came up with are as follows.

Considerations:

1. The springs need to point in a direction that allows the

compressor shaft to be pulled, not pushed, by the springs.

2. The minimum air gap between the clutch disk and pulley

needed to remain at the stock distance of about 0.020". I

could use a wider gap if the new springs had less tension than

the original rubber spring.

3. The springs needed to be raised on the center hub enough to

allow them to flex at least 0.020" without having to bend

around the center hub.

4. The relationship between the height of the center hub and

the clutch plate needed to stay the same as the original

parts. This worked out to 0.155" between the top hub and

clutch plate. (See 2D drawing below.)

5. I would use the 0.044" shim that came under the clutch hub

to try and maintain the 0.020" air gap. I would purchase an

assortment of additional shims in case the air gap needed to

be greater than the original 0.020" gap.

6. I would need to add a disk or washer on

top of the springs to prevent the springs from flexing the

wrong direction with the AC in the off position.

Unknowns:

1. Amount of magnetic force generated by clutch coil.

2. Amount of force necessary to turn AC compressor.

3. The needed thickness/stiffness of the springs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The nice thing about a clutch using the flat spring design is

that it won't self-destruct if the clutch plate gets hot. All of

the parts on the clutch disk assembly are steel. Unlike the

rubber "spring" on the original clutch, overheating the clutch

plate will not ruin the new steel springs. This clutch should

last for the life of the air conditioning system.

Update: May 2015

The new compressor clutch worked for about 2 months, then broke

two of the clutch springs. I was a bit baffled by this. The

breaks occurred were I had bored the holes to attach the spring

to the outer disk with steel rivets. The breaks appeared to be

from an undue amount of stress at this connection. The steel

rivets had almost been sheared. Very strange. I checked the

compressor and the shaft turned freely, so I assumed that it

hadn't locked up. I made some new springs from thicker stock -

some 0.032" feeler gauges - and we put it back together and sent

my son on his way. Two months later, we had the same situation

again. This time one rivet had sheared and two of the three

springs had broken. My son sent me the clutch through the mail

and I didn't have a chance to check the compressor this time. I

rebuilt the clutch yet again and waited until the next time he'd

be in town to install it.

When he came up, I went to install the clutch again, we found

that the compressor shaft was locked up tight when trying to

rotate it clockwise. I was able to turn it counter clockwise.

When I again tried to turn it clockwise, it now turned. It now

appeared that we had an internal problem in the compressor. The

whole situation was now beginning to make more sense. The

compressor was the cause of the first burned up clutch, as well

as the two subsequent clutches.

Michael ordered a new compressor from http://www.justforjeeps.com/accompressor1.html

and also ordered a new receiver drier in case some metal

shavings got into the lines. We got the compressor and

receiver drier installed last week. I would have liked to have

stripped down the compressor and find out what had happened,

but there was a core charge on the old compressor that he

didn't want to lose out on. So I guess that we'll never know

the reason for the compressor locking up randomly, but I guess

that's life.

To add insult to

injury, the air conditioning clutch coil on my Dodge 2500 died

a few days before we installed his compressor. The coil is

inexpensive as an aftermarket part, but the coil is controlled

by the fuse box which is properly named the Totally Integrated

Power Module (TIPM). The TIPM saw that the coil was drawing

too much amperage and has shut down that circuit. I have the

coil installed, but am presently waiting on some software from

AutoEnginiuity that may allow me to reset the TIPM. If this

proves successful, I may write up the procedure. Always

something to keep me busy.

© Fager November 28,

2014