When we arrived home, I

took the truck straight to my shop and tested the AC system.

If you don't have an advanced scanner that will pull all of

the diagnostic trouble codes (DTCs), you can check for power

and ground at the AC compressor clutch coil. I had voltage

but the compressor wasn't kicking in.

I spent the evening

reading my Dodge workshop manual and everything else I could

find about the compressor coil and how it is activated. What

I read didn't please me much at all. It seems that the

clutch coil gets its power from the fuse box. However, the

fuse box is no longer just a panel with wires and fuses. The

fuse box is actually named the Totally Integrated Power

Module (TIPM). Instead of external relays to control things

like the compressor clutch coil, it uses solid state

devices. If it sees that a circuit is pulling too many amps,

the TIPM can and will shut that circuit down. Apparently

that is what has happened to mine.

|

|

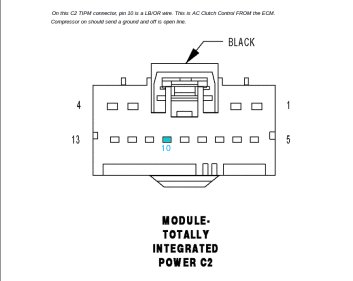

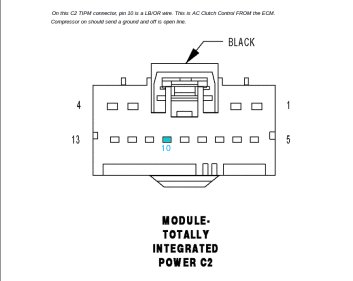

The

black C2 connector on the back of the TIPM.

Click the image to read the notes.

|

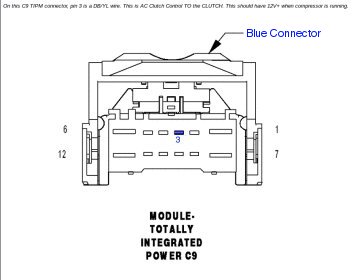

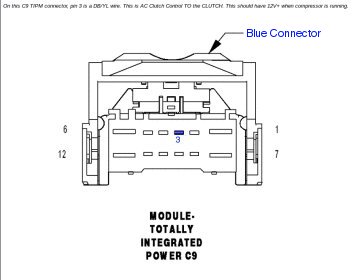

The

blue C9 connector.

Click the

image to read the notes.

|

When I jumped the compressor clutch coil

directly from the battery, the coil was able to pull in the

compressor clutch, giving me AC again, but it was is pulling

6+ amps. The spec for the coil in my workshop manual stated

that it was supposed to only pull 4 amps maximum. When

checking the two wires that go to the coil connector from

the TIPM circuit, I was reading about 11 volts, which was

within specs, but the circuit carried no amps at all. It

wouldn't even light a test lamp. What I though was strange

is that if I grounded one of my voltmeter probes and probed

either of the two wires going to the coil connector, both

were showing the same 11 volts. It appeared that something

was amiss in the TIPM as well as the compressor clutch coil

drawing too many amps.

I started trying to perform the diagnostic checks in the

manual, but to do most of them, you need some way of reading

the voltages in the system. This is done at the dealer by

using the StarScan ODB scanner or similar. I didn't have one

of those. There is an interesting thread on the clutch coil

and a possible work-around here:

http://www.cumminsforum.com/forum/3rd-gen-non-powertrain/306332-possible-diy-fix-ac-compressor-clutches-going-bad.html.

While this work around wouldn't work for me as the output

from the wires going to the compressor coil couldn't produce

enough current to activate a relay, reading through the

whole thread gave me a little better understanding of what

was going on in the circuit.

|

|

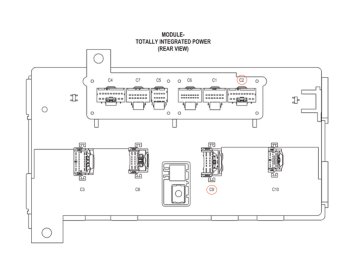

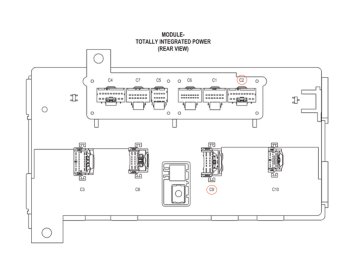

An

image of the back side of the TIPM showing the

locations of the plugs.

|

C9 plug removed from the TIPM so I could

isolate the wire.

|

I pulled out the TIPM and checked the dark

blue wire with a yellow tracer coming from pin 3 of the C9

connector of the TIPM and found that I had the same ~11

volts I had at the compressor connector. This is supposed to

be the positive wire to the clutch coil. The negative wire

on the compressor connector appears to go through the AC

pressure transducer on the side of the compressor and

eventually to ground. I then checked what was said to be the

trigger wire to supply power though the DB/Y wire just

mentioned. This wire is on connector C2 pin 10 and is light

blue with an orange tracer. It comes from the powertrain

control module on the diesel model and should supply a

ground to the TIPM when the AC switch is activated. I got 11

volts when I probed this wire.

For a test, I probed the LB/OR with a grounded probe. This

would cause the compressor coil to activate, but not stay

activated. It would pulse the clutch on, then off, three or

four times and then stay off. If I removed the probe and

then probed again, the same on - off routine would start

again.

I tested all of the components in the system the best that I

could without having StarScan and even pulled the center

dash to check the operation of the AC switch. As far as I

could tell without the proper diagnostic tools, everything

appeared to be working up to the powertrain module or the

TIPM.

We needed to use the truck the next day and it was going to

be hot, so I worked up a quick and dirty switch to a relay

to power the compressor. The AC worked fine in the morning,

but only lasted 1/2 day. I lost the ability to turn the

compressor on around noon and we spent the rest of the

afternoon driving in a hot truck - or at least I did. My

wife picked up her Lexus from the upholstery shop and got to

drive home with AC. I had to sweat.

|

|

The

wire is removed by inserting a thin screwdriver

under the connector.

|

The

wire is removed.

|

When I got home, I put

an ohm meter across the coil terminals and it had died. Open

circuit. There was nothing more that I could do at this

point but to order a new coil. I ordered the coil from

coldzone111 on Ebay - $45.77. The seller had great ratings

and a few of the comments gave a thumbs up on this coil.

I had also done some

more reading in the manual and found that every test was

prefaced by making sure that you checked for trouble codes

and repaired those first, then cleared the codes. I needed

some way to do that. I decided on the AutoEnginuity (AE)

software and dongle along with the Chrysler add-on software.

My main reason was that I could add the Toyota/Lexus package

for my wife's car if we needed it in the future. The AE

Chrysler software would also let me pull codes from my son's

Hemi Ram and his wife's Jeep JK. If I had no other vehicles

to consider, I might have gone for one of the performance

programmers that also pull and clear codes. At almost $500,

the AE software, dongle, and Chrysler add-on wasn't cheap,

but I figure it will pay for itself eventually. I sent the

AutoEnginuity folks a couple questions from their contact

page and was pleasantly surprised when I received an answer

back within a few hours. Their support has been surprisingly

good and this is something that you can't say about many

companies these days.

|

|

The

C2 connector has been removed and the white

plastic protector has also been pried out.

|

The

white plastic pin connector has been reinstalled

|

I received the coil in a couple days. Pretty

quick shipping and the coil looked good. Installing the coil

without removing the compressor from the truck was a pain in

the butt. It is easy enough to pull the 4 bolts to drop the

compressor, then pull off the clutch plate, pulley and coil,

but trying to line up the coil and press it back on while on

your back under the truck is not a whole lot of fun. It took

a couple tries before I got the coil fully seated. An

inspection mirror on a stick allowed me to look at all sides

of the coil and make sure that it was seated as far as it

would go. To allow me to press on the coil, I used a 1"

thick ring of aluminum that I had saved in my metal scrap

bin. A wooden ring about the size of the coil would work

just as well. I placed this on top of the coil then placed

the clutch disk on top of that and used a longer 6 mm bolt

in place of the stock clutch disk bolt. I ran the bolt down

as snug as I thought a 6 mm bolt could handle, then tapped

on the clutch disk with a compothane "no bounce" hammer.

This is a plastic hammer with metal shot inside and may also

be referred to as "dead blow" hammer. Once I got the coil to

move a bit, I retightened the 6 mm bolt and repeated lightly

hitting the clutch disk. I repeated this until the coil was

fully seated on the compressor.

|

|

There

are four bolts to unhook the compressor.

|

Using

a too-small puller to remove the AC compressor

pulley. This barely worked.

|

I used the same technique to install the

pulley. It was slow going, but I finally got it seated. I

should have removed the clutch disk and inspected it and the

pulley face before I ordered the coil. If I had, I would

have ordered a new clutch disk and pulley at the same time.

My clutch disk and pulley are no longer flat where the

contact each other. There are grooves where the clutch disk

has been slipping against the pulley face. I will order the

new parts soon, but am guessing that the current ones will

last throughout the summer.

With the new coil installed, I ran a couple wires from the

battery to test it. It worked well and I again got cold air

from the vents. Since I didn't know what fixing the TIPM was

going to entail, I wired up a switch and relay so that I

could manually control the compressor clutch from the car.

This time I wired the relay coil hot lead (terminal 86) to

the #40 (20 amp) fuse in the TIPM which gives power to the

cigar lighter when the ignition switch is on. I wired the

negative side of the relay coil (terminal 85) to a switch

that I attached under the dash to one of the trim screws.

The other connector on the switch was wired to ground under

the dash. The power lead of the relay (terminal 30) was

wired directly to one of the batteries through a 15 amp fuse

and fuse holder. The power output of the relay (terminal 87)

was wired to the plus side of the compressor connector. I

ran a wire from the negative terminal of the battery

directly to the negative side of the compressor connector.

This worked well for the one day I needed to use it before

my AE software arrived.

The temporary circuit to control the AC compressor clutch

coil is NOT a fix that I would want to use for an extended

period of time. If you need to use this circuit, you should

be aware that there is no component in the circuit that will

shut off the compressor if the Freon pressures become too

high. A safer circuit could be made by adding a high

pressure switch in place of the AC transducer and wire this

switch between terminal 85 of the relay and the on/off

switch. Without a way to shut off the compressor clutch coil

when the system pressures rise above the recommended level

(460 PSI), you stand a chance of AC compressor damage or

leaks caused by too much pressure. If I was looking to make

a circuit that would be used for a longer time, I would also

need to find a way to increase the flow of air over the AC

condenser when the AC is used when idling for extended

periods of time, such as stop and go traffic.

I finally got the AutoEnginuity software. I had a little

trouble getting it installed, but wouldn't have had the

trouble if I ran more current Windows software. I run Linux

exclusively these days. I had a couple of old laptops that

came with Windows, but had been switched to Linux before

they were retired. One had come with Windows 2k Pro and the

other with WinXP Pro. I had decided to remove the Linux on

the newer of the two and reinstall the XP software that came

with it, but I couldn't find the disk. I did find the Win2K

disk and since it was supposedly supported by the AE

software, installed Win2k. When I went to install the AE

software, it installed OK, but when I went to open the

Giotto program that runs the scanner, I got an error:

ScanTool.exe - Entry point not found

The entry point is Wow64process and could not be

located in the dynamic link library Kernel32.dll |

It looked to me like the software was looking for a 64 bit

kernel on a 32 bit machine. I couldn't find anything on the

AutoEnginuity site, so I sent them an email. This was very

early in the morning and they hadn't opened yet. I decided

to do some sleuthing on my own. I pulled out an old desktop

computer with WinXP Home version on it and loaded the AE

program. This time when I went to launch it, it launched

without error. Hmmm. For some reason, it looks like the

software didn't like Win2k.

|

|

The

compressor pulley and coil have been removed and

the snout on the compressor has been cleaned and

lightly oiled.

|

The

compressor clutch disk has been wearing for the

past nine years. The face of the pulley has the

same wear lines. I will replace both soon.

|

I again dug through the

last 10 years worth of CDs and this time I came up with the

original XP disk for the laptop I had installed Win2K on.

Rather than do a fresh install, I just ran the upgrade.

About 40 minutes later, XP pro was installed. Since this had

been an upgrade and not a fresh install, the shortcut for

the Giotto scan program was still on the desktop. I clicked

it and the program launched. AutoEnginuity got back to me a

little later with a couple things to try, but I had already

solved my issues. Still, having anyone's support get back to

you the same day is pretty darned good.

Apparently the Chrysler

add-on program is loaded from the main installation disk and

that the dongle is coded to allow you to activate it. I was

a bit surprised that there wasn't a second CD to load. My

dongle didn't seem to be programmed to allow me access to

the Chrysler add-on package and gave the folks at AE a call.

While we were on the phone, I received an email with the

code to activate the Chrysler package. This did the trick

and once I got it activated, I was presented with more

screens and options than I knew what to do with. Most of the

options are abbreviated like HVAC for the heating,

ventilation and AC system. I was in the automobile service

industry for a couple decades and know my way around cars

pretty well, but many of the abbreviations meant nothing to

me. It is going to take me a while to get full use of this

product.

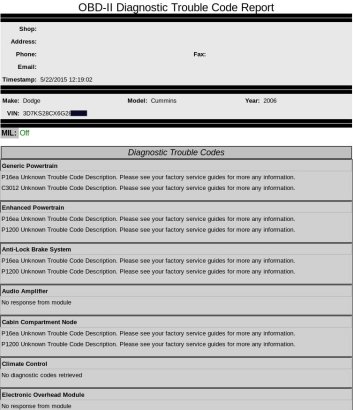

With some help from a

post on one of the diesel forums, I discovered that if you

click on "Change System" to "TIPM" then go to "Test

OnBoard System" tab --> "module configuration" you can pull

the diagnostic trouble codes (DTCs) for that system. You have

the choice of All, Current, or None. I chose current. I got

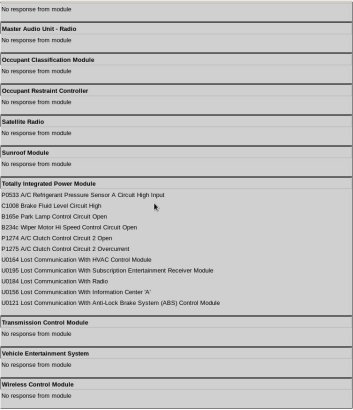

quite a long list - see the images below. I realized that

probably quite a few of these were from my pulling connectors

during my trying to diagnose why I had no ground on the LB/OR

wire on connector 2 of the TIPM. I decided that I would print

out the DTCs and then clear them to see if any came back.

Clearing the codes is a bit non-intuitive. The button to clear

them reads Clear MIL. MIL is the multifunction indicator

light. It was not on, so why would I need to clear it.

However, this button also clears the DTCs. When you click it,

you again have the choice of All, Current, or None. I chose

Current. Once you clear the codes, you're asked to cycle the

key switch to off, then on. I did this and pulled the codes

for the TIPM again. There was now only one single entry about

being able to communicate with the CAN bus. I figured that

since the workshop manual was adamant about having the codes

cleared before you tested the system, that it was worth a try

to unplug the dongle and fire up the truck. I started the

truck and hit the AC switch. The engine lost a couple RPMs as

the compressor clicked in and I again had air conditioning. I

did not clear the TIPM and am not positive that the AE

software will even allow me to do this. There is an option for

clearing the ECU, but I will do some more research on this

before I start messing with things that I am unsure of.

|

|

This

is the top portion of the AutoEnginuity ODB

trouble code report I ran after replacing the compressor

coil.

|

On

the bottom half of the report, you can see all of

the DTCs that pertain to the TIPM. I believe I set

most of the codes while checking the TIPM plugs.

|

I'd

like to give my thanks to the forum members over at

CumminsForum.com for getting me headed in the right direction

on this repair. The thread linked above saved me a lot of time

trying to diagnose this issue and hopefully this article will

add to the general knowledge about this repair.

On

the flip side, I am really disappointed in

Chrysler/Dodge/Jeep. I have read about countless problems due

to too strict of parameters being programmed into the TIPM.

The problems range from this AC issue, to vehicles not

starting, to having a headlight burn out and having to have

the TIPM system reset after you install a new headlight. What

kind of company makes a headlight replacement something that

has to be done at the dealership - even if a headlight

replacement is a little more involved (and much more

expensive) than the old "sealed beam" type headlights? I have

to say that this type of engineering makes me angry. Is

shutting down an electrical circuit when it gets a reading out

of it's intended parameters really any better than just have a

fuse pop if a circuit draws too much amperage? I guess if your

mission is to overly complicate the vehicle and tie the

customer to the dealership, it is.

I like

my Cummins diesel a lot, but it's almost 10 years old. I have

been toying with the idea of a new one. However this

experience has soured me on buying a new Dodge. I can't see

giving my hard earned money to any company who tells me that I

need to come back to their service department and pay them to

reset the system after I have replaced my own headlight.

Keeping this old truck going has much more appeal than it did

last week. Also, I think it is time that I start reading up on

what other car manufacturers are doing. I already hate the

idea of General Motor's OnStar system tracking the owner's

every move. I am hoping that I find one manufacturer out there

that doesn't feel that they have the right to track me or lock

me into their dealership network for simple repairs.