|

Repairing a Dodge Ram with the Death Wobble

October 30, 2014

A few weeks ago, our

son called and told me that he now knew what the dreaded Dodge

death wobble was and that it scared the crap out of him. He was

driving at interstate speeds and hit a good sized pothole. The

front end of his 2006 Ram 2500 Hemi 4x4 quad cab started shaking

violently. The only way he got it to stop shaking was to slow

the truck down to around 35 MPH in the fast lane of interstate

95. He finished off his trip in the slow lane driving well below

the posted speed limit. Since that day it has been getting worse

each time he drives it. He asked if I could help him get rid of

the wobble. I asked when he wanted to start work on it.

His truck is lifted a

couple inches in the front using a Rough Country Leveling Kit

[#9219] and he's running BF Goodrich 315/R70/17 All Terrain

tires. I have the same tires but haven't installed the springs

yet. They've been sitting under the bench for a couple years

now. Before we went to the larger tires, we both had read as

much as we could about larger tires and lifting the trucks. In

the process of the research we had come across talk about the

death wobble. We both knew about it, but neither of us had

experienced it. He has about 80k miles on his truck and I have

about 62k on mine. Not a lot of miles on either of them

considering they're eight years old. He does a lot of driving ,

but has a couple of vehicles to split up his driving mileage and

I now work from home and don't drive nearly as much as I did a

few years ago.

While we were over

visiting his family a week ago, I crawled under his truck and

took a look at the front suspension. He only had a short pry bar

to loan me, but I checked for steering play as best as I could

with the tool I had. The track bar seemed a bit too easy to

move, so we'd need to get some new track bar bushings to start

with. He ordered a set of Luke's Link Track Bar Bushings. These

are polyurethane replacements for the rubber bushings that come

on the truck. I also thought that a couple of the tie rod and drag link ends were

suspect, but I would need to do some measuring before I could be

sure of that. We decided that he'd come up to our house once the

bushings arrived and we'd do as much as we could in one day so

that he could make the 120 mile trip back home that same day. He

has his own family now and would rather be with them than spend

the night at mom and dad's. I don't blame him.

|

|

Mike's

truck a few years back when we had just added the

front springs, rims and tires.

|

The

old tie rod is held in the vise so we can get some

measurements.

|

He arrived mid-morning

with the track bar bushings in hand and we got to work. First we

put the front end up on jack stands. One under each side of the

front axle tubes. I did a shake test of each front wheel. I

grabbed the driver's front tire at the 12 o'clock and 6 o'clock

positions and tried to shake the wheel. This is done by pulling

on the 12:00 position as you push on the 6:00 position and then

reversed by pushing on the 12:00 position and pulling on the

6:00 position. Back and forth, back and forth, and repeat a few

more times. I felt some movement, but not a lot. I thought that

this was inconclusive, but warranted further investigation. I

have to say that this is a lot easier if you're working with a

passenger car with normal sized tires. The big 315/R70/17 BF

Goodrich All Terrain tires are heavy and resist being shaken by

anyone smaller than the incredible hulk. As I said, I felt some

movement, but nothing definite at this point. I tried the shake

test again using the 9 o'clock and 3 o'clock positions. This

time there was more movement. There's definitely some play

somewhere that's not supposed to be there. The big question is

where. A certain amount of movement is normal as the steering is

meant to move. If the steering wheel lock is not engaged, you

will see the steering wheel move as you perform this test. For

all but the dealer mechanics, who work on these trucks daily and

know by experience how much play is normal, it is probably a

good idea to lock the steering wheel for this test. With the

wheel locked, pretty much all movement you feel while shaking

the wheels at the 9 and 3 positions will be unwanted

looseness/slop.

We repeated the test on

the passenger side front tire. The results were about the same

on the 12 and 6 o'clock positions, but much worse on the 9 and 3

o'clock positions. OK, we've got some slop, but where? This is

what we would now try and discern. The next test was to get out

the dial indicator with a magnetic base and test the upper and

lower ball joints. My Dodge workshop repair manual gives an

overview of this procedure, but doesn't tell you where you

should mount the dial indicator base. This is pretty typical for

a factory workshop manual. You are expected to know that the

base of the indicator needs to be attached to something that

won't move in the same plane as the part you are testing. After

all, you are a Dodge mechanic and have done this test countless

times, right? Well, maybe. For those of us who aren't

professional Dodge techs, attach the base to some part of the

body that doesn't move with the front suspension. For testing

the ball joints, I found a spot to attach the indicator base on

the sheet metal next to the coil springs. The indicator plunger

is placed on the steering knuckle next to the nut on the ball

joint shaft. The plunger needs to be aligned to the vertical

plane so that when you pry against the ball joint shaft and the

cup that the shaft and ball reside in, you can measure the

amount of movement. In this case it is up and down. With the

indicator set up, I pried between the axle tube yoke and the

knuckle. I got a reading of 0.040". I set the dial indicator

back to zero to the test for the lower ball joint. This time you

set up a jack stand and use it as the fulcrum for your pry bar.

Pry upwards on the flat part of the steering knuckle next to the

ball joint stud and nut using the jack-stand as the fulcrum.

Record your movement. Ours was 0.041". Add these together and it

shouldn't be over 0.090". Our combined reading on the driver's

side was 0.081". Not worn to the point that Dodge recommends

replacement, but close. We repeated the tests on the

passenger side and came up with total movement of 0.087". The

ball joints were testing close to their limit and we discussed

replacing them, but we still had more tests to perform.

|

|

Measuring

how far to screw on the tie rod end so that the new

tie rod is the same length as the old one. I'm not

hiding from the camera... Really.

|

Measuring

the total length so that the new tie rod is the same

length as the old one.

|

Next

on the agenda was testing the tie rod ends. The test

procedure is similar to the ball joints; mount the indicator

base to something that won't move, put the indicator plunger

on the joint side of the tie rod end and use a pry bar to

force the joint apart and measure how much the joint lifts

away from the bolted side. The one thing to look out for is

that the tie rod ends don't swivel while you are trying to

measure them. You don't want them to swivel because of the

possibility that you would end up measuring the swivel

rather than the actual play. You need to use your pry bar in

such a way as to try and force the joint apart without

introducing any swivel in the joint. The driver's side tie

rod end passed at about 0.010". The joints at the Pitman arm

and passenger side tie rod both failed. Both were well over

the 0.020" amount of allowable play. These joints had grease

nipples. I asked my son how often he had been lubing them

and he gave me a bit of a blank stare. Hmm, I guess they

weren't getting enough lube. We discussed what repairs we

wanted to do. To upgrade to the 2008 style steering, we'd

need to replace the steering linkage (tie rod and drag

link), Pitman arm, and the steering damper. This would be

the best way to go as it changes the geometry from the

inverted Y to a T shaped configuration. The T style

configuration is a better design due to the ability to

maintain a constant toe-in measurement as the suspension

travels up and down. The inverted Y style wasn't the best

design choice in my opinion.

The best price I

found for the newer T style components online was $339 +

shipping. From the dealer, it would be more than $500 and we

still didn't know if we were going to need to replace the

ball joints. If money were not a concern, we'd have gone

with the new 2008 style steering setup. However with a new

baby in their household and having just moved, he wasn't

exactly flush with cash. We decided to replace only the

parts that were way over spec and see if that would get him

on the road without the wobble. If not, we'd do the ball

joints as well. We were also replacing the track bar

bushings and the added stiffness of the polyurethane

bushings should help to keep the front end from moving in

unwanted directions. Hopefully we'd be able to make a big

improvement in the wobble without spending a small fortune.

With all of the reading I had done on the death wobble, I

had found that quite a few folks had replaced a lot more

parts without curing the wobble. I was hoping that this

wasn't going to happen to us.

In the

process of stripping down the truck for inspection, we found

that the front brake pads were getting low. We also found

three snapped lug studs on the passenger side front wheel. A

couple months back, he had the truck in for an alignment and

while I hesitate to place blame, the truck came back to him

with the steering wheel off center and the front lug nuts so

tight that we needed a breaker bar with a cheater pipe to

get them loose today. Somehow I don't think they used a

torque wrench to set the lug tightness. They also missed the

fact that there were loose joints in the steering system. I

was not impressed with their work.

|

|

Test

fitting the new tie rod and drag link.

|

The

shop is just tall enough to handle the truck with

the 315 tires and a small lift.

|

I

was planning to do the alignment myself, in the garage, with

a tape measure to set the toe-in and I had a Joe's Racing

28210 Caster Camber Gauge so we could check and set the

camber and caster. While I will be the first to agree that a

high dollar alignment rack is a better tool for the job, to

get a good alignment, the operator of that machine has to

know and care about the job he/she is doing. Finding a good

alignment tech is much harder than finding a good alignment

machine. I have done many hundreds of alignments on all

kinds of equipment during my time as a mechanic and

considered myself a decent front end tech, but that was many

years ago and I worked on imports not American trucks. That

said, taking alignment readings is pretty much the same on

all cars/trucks. The difference is in how the adjustments

are made. The biggest advantage to having me do this

alignment is that I have a vested interest in making sure

that it is as close as it needs to be. I will also be able

to monitor how the truck drives, as well as monitor the tire

wear and make adjustments if they prove necessary.

Because we were

trying to fix this issue on the cheap, we decided to go with

aftermarket parts. We made up a list and headed to the local

auto parts store. After some trouble finding the right parts

on their computer catalog, we finally thought we had found

the right stuff and ordered it. The Advanced Auto Parts

numbers for the tie rod and drag link were DS1464 and

DWDS1463. It was 2 PM and they said they'd have the parts by

4 PM. We hoped so. It was going to be one of those late

night marathons. Unfortunately, they didn't have stock of

the lug studs and couldn't get them today. At $4.95 each, I

thought they were a bit expensive anyway. We had a couple

hours to kill, so we decided to go to the local Dodge dealer

and get the studs. They didn't have any either and they

wanted almost $15 each. They must be really nice studs at

that price. We finally found them at a NAPA store for a

little under $5 each. I guess that $5 is the going rate.

We headed

back to pick up the steering parts and were pleased that not

only were they there at the time he had promised, but they

looked like the correct parts. They gave my son (who is in

the Army) a military discount and we were on our way home. A

tie rod link, a drag link, and some semi-metallic brake pads

for under $185. Not too horrible.

It was already 4:30

and we had not yet started putting the new parts on the

truck. We were going to be here for a while. Michael got

started doing the brakes and I started transferring parts on

the suspension. The driver's side tie rod end was good, so

it was getting transferred to the new center link that comes

with the passenger's side tie rod end. I measured the

distance between the two tie rod ends and made sure that

when assembled, the total length of the new part was the

same length as the old one. I did the same with the drag

link. Before we installed the steering linkages, we decided

that it would be easier to replace the track bar bushings

without the new parts in the way.

|

|

New

red track bar bushings and what is left of the old

ones after being pressed out of the track bar. The

old socket fits the outer bushing sleeve well.

|

Pulling

the suspension over a half inch. The chain is

attached to the diff tube yoke, then to the

ratcheting chain binder.

|

The track bar is held in by

two bolts; one at each end. The nuts that secure the bolts have

a sheet metal flag welded to them. The flag allows you to

position the nut into a space where your fingers couldn't get to

if you had a nut without this extra long handle. I applaud the

engineer who designed this feature. Without the flag, it would

be near impossible to get the nut positioned. As it is, getting

the passenger side nut centered on the bolt is no easy feat. The

one on the driver's side is much easier. With the track bar out,

we pressed out the rubber center of the bushings on my 20 ton

shop press. The next step was pressing out the thin outer

stamped metal shell of the stock bushings. Fortunately I have a

bunch of old 1/2" drive sockets that get used as press tools

from time to time. This was one of those times. The socket we

chose was almost the perfect diameter, but I got it a little

cocked on the second bushing and flattened out one of the edges.

This required me to use a cold chisel and punch to deform the

lip of the bushing enough that we could then press it through

the track bar. Not a big deal, but another 20 minutes spent on a

job that should have taken five.

Getting the track bar back in was a bit of

a chore. We installed the passenger side first and it took a

while to get that flag nut on the bolt and finally get it

cinched down. When we lifted the driver's side of the track

bar into position, it didn't fit. It was about a half inch too

short -- too far toward the passenger side. Apparently the

suspension had shifted a bit when we pulled out the track bar.

I knew that we needed to pull the suspension toward the

driver's side of the truck and I had a come-along that would

do the job, but I had loaned it out and it wasn't back yet.

What to do? I finally remembered that I had a chain binder

that could serve as a puller. We hooked the binder up to a

chain with one side hooked to the area near the differential

tube's passenger side shock mount. The other end of the binder

was hooked to the body of the truck on the driver's side. A

few turns of the ratcheting chain binder pulled the axle

housing closer to the driver's side and we were able to put

the bolt through the track bar and cinch it tight. Success.

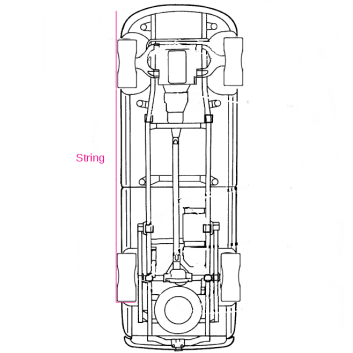

Installing the

steering linkages didn't take long. When we had everything in

place, it was time to align the truck. We let the truck down

off of the jack stands, started it up and more or less

centered the steering wheel. The next step was to get the

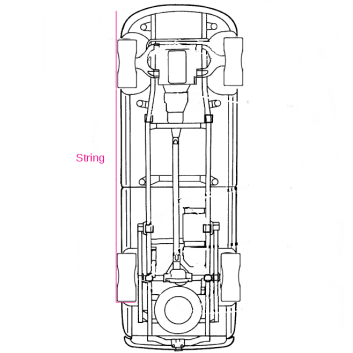

front wheels straight with the rear ones. The easiest way to

do this without an alignment machine is with a long string.

Have one person hold the string half way up the rear tire's

tread. If you do this on the rear facing side of the tread and

stretch the string forward to just in front of the front tire,

the string will contact the rear tire's side wall in two

places. Your goal is to get the string to also contact the

same side front tire in two places. Turn the steering wheel

slightly until you have achieved this. Now move to the other

side of the truck and check to see if the string will contact

both tire's sidewalls. Chances are that if you measured the

placement of the tie rod ends correctly, it will be close. If

it is not close to contacting the side wall of the front tire

in two places, spin the adjusting sleeve on the tie rod

(lowest of the two bars with adjusters). One direction will

move the front edge of the front tires farther apart. The

other direction brings them closer together.

|

|

The

hole in the track bar bushing now lines up with the

hole in the mount. The mount is the bright piece on

the upper right.

|

The

chain binder was attached to a gap in the frame on

the driver's side. My come-along would have been

better, but the chain binder worked.

|

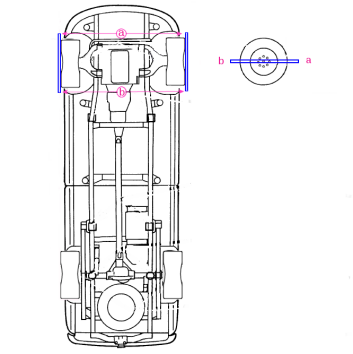

With the front wheels now pointing straight ahead, you

can check the toe-in. For this truck, the spec is 0.10° ±

0.05° toe-in per side. This would mean a total toe-in of from

0.10° to 0.30°. I wanted 0.15° total toe-in which works out to

about a 1/8" difference between the front and rear readings

using the method I will describe. This is a two person job.

You will need two straight sticks that are four feet long. We

used a couple four foot fluorescent tubes. How's that for

making use of what you have? I'll call these sticks just to

make it easier to type. Center the sticks on the wheel so that

the overhang of the stick on each side of the wheel is the

same. The sticks should be parallel with the ground and placed

around the center of the wheel. Place the hook end of a tape

measure over the front end of the stick and have one person

hold it in place. The second person holds his stick and the

body of the tape measure and measures the distance between the

sticks making sure that the measurement is taken on the front

end of his stick as well. Note the reading. Our front reading

was 64 3/8". Now move the tape measure to the rear end of the

sticks which will be behind the front tires. Make sure that

you hook the tape measure to the same relative spot as you did

in the front. Take your reading. Ours was 65". Subtract the

front reading from the rear (65 - 64 3/8). This gave us a

total toe-in of 5/8", which is too much. If the front reading

was larger than the rear, then you have toe-out and you'd want

adjust it until you have toe-in.

At 5/8" total toe-in, we had a 1/2" too much. This means that

the length of the tie rod needs to be expanded to widen the

distance between the front edges of the tires. If your

measurement was larger in the front (toe-out), then you will

need to lessen the length of the tie rod. If I recall

correctly, it took a few turns of the adjustment tube to

remove that extra 1/2" of toe-in. We remeasured again and had

64 5/8" for the front measurement and 64 3/4" for the rear. 64

3/4 - 64 5/8 gives us 1/8" toe-in and this equals 0.15° when

using a 4 foot stick. When you are sure that the tie rod

adjuster has been set to give you the toe-in you want,

make sure that the tie rod end on the driver's side is

centered and not tilted to either side. Hold the adjuster

sleeve tight and spin each of the clamps to where you can

tighten them up and lock the adjustment. You get bonus points

if both the clamps are lined up and pointing in the same

direction. You don't want it to look like you aligned the

truck in your garage, do you? At this point, your steering

wheel may not be straight. You can lengthen or shorten the

length of the drag link, using the adjuster sleeve, to change

the position of the steering wheel. You can go ahead and do

this now, but don't tighten the locking nuts up all the way as

you will want to refine your setting when you take your test

drive and find out what position the steering wheel is when

you are on a flat road traveling straight ahead.

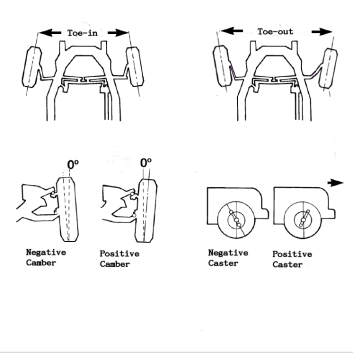

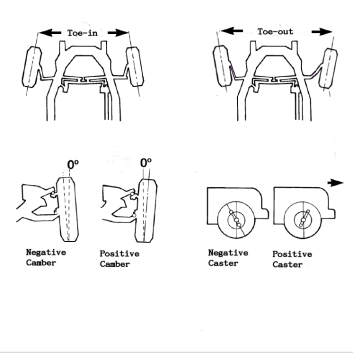

The next step was to check the camber and caster. Camber is

the tilt of the front wheels when you are looking at the

wheels from a viewpoint in front of the truck. If the tops of

the tires tilt toward each other, it's negative camber. If

they tilt away from each other, it's positive. The spec for

the 2006 2500 4X4 is 0.25° ± 0.50° positive individual camber.

You will notice that the plus or minus a half degree means

that the camber can range from 0.25° negative camber to 0.75°

positive camber on each front wheel. I would prefer to see a

small amount of negative camber on a vehicle. To measure the

camber, you just stick the gauge on each front wheel's center

hub, over the big axle nut, level the gauge with the little

bubble level in the end of the tool and take your reading.

Bounce the front end a couple times and check it again. Our

readings showed a hair over 1/4° negative on each wheel.

Nothing needed to be done. Both sides were the same and just a

tiny bit more negative than the Dodge spec. Close enough for

government work.

Caster is the front to

rear tilt of the steering axis. If you could see the ball

joints from the side of the truck, you'd see that if an

imaginary line was drawn through the upper and lower ball

joints it would be slanted with the top of the line rearward

to the bottom of the line. The lower ball joint is further

forward than the upper one. If you compare the truck's caster

angle to motorcycle front forks, a street bike has less caster

angle than a chopper with a long front fork. Both are negative

caster, I.E. the top of the fork is behind the bottom of the

fork. The street bike with less caster is quicker to turn but

gives up some stability at speed. The chopper with it's long

front end (much more caster) is stable as a rock at speed, but

gives up low speed maneuverability. The effect of the caster

angle on the truck is similar, but not nearly as exaggerated

as the example I gave.

|

|

The

three basic settings in an alignment. Toe-in, camber

and caster.

|

Getting

the wheels straight. The red string is held on the

rear tire tread and contacts the sidewall on two

places on each wheel.

|

Checking the caster is a bit

more involved, but with the Joe's Racing camber/caster gauge or

any of the gauges with a magnetic attaching adapter, it is easy.

Note that I did need to modify my gauge's adapter to get it to

fit over the large axle nut. This was a quick job on my lathe

where I increased the diameter of the center hole by about an

eighth inch, but I think that the company also sells a larger

adapter that will clear the nut without resorting to

modifications. If you are going to order one of these gauges,

measure the widest point of the front axle nut and washer and

compare it to the adapter.

To check the caster,

you need to turn the tires about 40° to take your measurements.

The pro alignment machines have swivel plates marked in degrees

that the front tires sit on. This allows you to easily turn the

wheels to their proper position to perform the caster test. I

have no swivel plates, but it's not a big deal. Some DIY guys

use cookie sheets under the tires to make them swivel easier. I

use nothing. The power steering will easily turn the wheels and

when I get to the angle needed, I rock the steering wheel a few

times to make sure that the tire is sitting squarely on the

floor at whatever the chosen position.

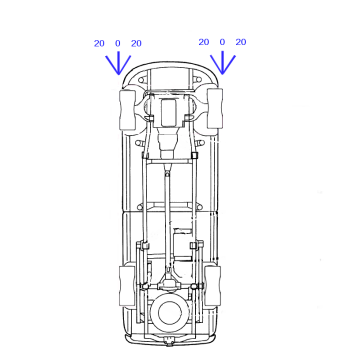

The first thing needed

is to mark the floor to give you the angle references. I placed

a strip of tape on the garage floor in front of each front

wheel. The tape is parallel with the front wheels and extends in

front of the truck about a foot. With a protractor, I placed two

more strips of tape beside the first piece. One starting

directly in front of each tire and extending at a 20°

angle to the left and one extending at 20° to the right. The

three pieces of tape form what looks like an arrow pointing at

the outside edge of each front tire. The procedure for checking

the caster is as follows. Turn the wheels 20° to the right --

parallel with your right tape line. Place the caster gauge on

the center of the wheel over the axle nut. Level the gauge using

the little bubble level closest to you. The caster bubble vial

is the center one of the three. There is an adjuster on it. With

the adjuster, set the bubble to be centered on zero. Turn the

steering wheel so that the right front wheel goes past your

center tape line until it is parallel with the left 20° tape

line. You have now moved the wheel 40°. Check to see where the

bubble is now. This is your caster reading. Ours was 5° and the

spec is 4.5° ± 0.5°. Now repeat the process on the left front

wheel. On this wheel, you start with the wheel lined up to the

left 20° tape mark, then turn the steering wheel to the right

until it lines up with the right 20° tape mark. Again, we found

we had 5° of caster. While the caster was right at the high end

of the spec, I had been thinking about it for a while and was

prepared to try increasing it to 6° if we couldn't get rid of

the wobble any other way. The extra degree might make the front

end less prone to wobble while we looked for other worn parts.

However, for the time being, nothing needs to be changed here

either.

Adjusting the camber

and caster is a little more involved than setting the toe-in.

It's not rocket surgery, but if you've never done it before, I

would advise having a service manual to refer to. There are

procedures that must be followed in order to get the job done

correctly and the adjustments change both camber and caster.

Setting both camber and caster involves moving the position of

the control arms using eccentric bolts in slotted holes. If you

need to adjust the camber or caster, you should recheck the

toe-in after the camber and caster have been set.

As for my thoughts as to why the caster and camber didn't need

adjustment -- it had been set correctly at the factory and

hadn't been changed since then. Unless you whack something

pretty darn hard, the alignment settings don't usually move. The

exception to this is worn steering parts can cause the alignment

settings to change. When you replace the parts, you must check

the alignment. Even though my son has had a recent alignment,

they did not adjust the eccentric cams on the control arms. I

know this because I had marked them with a punch when we had the

front end apart to install his leveling springs. They were still

at the same place I had set them almost 3 years ago and I set

them to where they had been before we loosened the control arms.

I figure that they probably did check the settings, but since

they were within spec, they didn't need to do any adjustments. I

did see one thing that I didn't like that I can attribute to

them. It appears that they had loosened the outboard clamp on

the driver's side tie rod and turned the tie rod end a bit. This

resulted in the tie rod end being tilted rather than being

perpendicular with the tie rod shaft and nut. The tie rod end

should be centered on the steering knuckle and it wasn't. Being

tilted, the joint's range of motion is restricted. This was the

tie rod end that we didn't need to replace, but if we had left

it tilted for an extended period of time, it would have worn out

prematurely. If they were trying to set the toe-in, both nuts

should have been loosened and the sleeve turned in or out to

make the adjustment. The inboard clamp nut had not been loosened

and was very stiff from rust. The sleeve had some rust as well

and hadn't been moved in years. It took a good soaking with some

penetrating oil and working it back and forth a bit at a time to

get it freed up. Anyway, enough of my complaining. I was pretty

confident that our current alignment was darn close and it was

almost time to take the truck for its test drive. We were sure

hoping that we had made an improvement in the wobble.

|

|

Using

two 4' sticks centered on each front wheel, you

measure distance "a" and "b". Distance "a" should be

1/8" to 1/4" smaller than distance "b" for a total

toe-in reading of 0.15° to 0.30°.

|

Use a

protractor to place some tape on the garage floor

marking out 20°, 0°, and 20°. This will give you

marks to line the tires up with when you check your

caster.

|

Before we backed the truck out of the shop, I crawled under the

front end one last time and put a wrench on each nut we had

worked on. Everything was tight except for the two clamps on the

drag link that I had just tightened enough to keep them from

moving until we could do the final adjustments on centering the

steering wheel. Mike backed out of the shop and we headed out

into the night. Before we even got off the gravel road and on to

the public highway, he commented that the steering felt a lot

tighter. It wasn't wandering as much as it had been. We got out

on to one of the back roads and he got the truck up to 50 or so

and hit a small pothole at speed. No wobble. When we reached the

highway, he got it up to 60 and ran over a few more dips and

bumps. So far, so good. No wobbles. After a couple miles we

found a flat, straight place to pull over. He backed up and

pulled forward with his hands off the steering wheel and let the

truck position itself straight ahead. He stopped and I got out

and crawled under the truck with my tools. The steering wheel

was pointing a bit to the right when it should have been

straight. I loosened both the lock nuts on the drag link

adjuster and turned the sleeve until the steering wheel was

centered. I repositioned the clamps and tightened the lock nuts

and we drove some more. The steering wheel was now centered. We

headed back home and cleaned up and called it a day. I asked him

to send me an email after he arrived home to let me know the

outcome of the drive. His two hour drive home down I-95 would

let us know whether the truck was fixed or not. I got an email

saying that it was a pleasant drive home. No wobbles and the

steering felt a lot better than it had in quite some time.

While we have only this one vehicle where we've seen the wobble

and apparently fixed it, I can offer my views on what I saw on

this truck. The wobble was fixed by replacing the worn out tie

rod ends - or in this case - the drag link and tie rod (center

link) that come with those joints. I am pretty sure that

replacing the track bar bushings helped as well. This is all we

changed. His BFG 315 tires are getting close to needing

replacement and the truck doesn't wobble. We did rotate the

tires so the tires that are now up front are nice and flat from

being on the rear of the truck. The tires that were up front

have some edge "cupping" which seems to be pretty normal for

tire wear on these trucks. My BFG's show a little cupping on the

front tires also -- as do the stock tires that now sit in the

shed. The cupping wear on both his and my tires is pretty minor.

You can feel a slight difference in tread height as you run a

finger over one tread to the next around the circumference of

both the inside and outside edges of the tires. Maybe if we both

rotated our tires a bit more frequently, we wouldn't see this.

As I said, the ball joints on his truck showed some wear, but in

this case the wear isn't causing the truck to wobble when

hitting pot holes or bumps at speed. This truck has the old

style power steering box and the steering box shaft that holds

the Pitman arm has a bit of vertical play. My truck which has

less miles and no wobble has the same amount of play in the

shaft so I didn't consider it an issue. I mention these items

because I kept reading that people were replacing these parts

without checking the basics and wondering why the truck still

wobbled. Again, I have only this truck to base my opinion on, so

maybe some trucks don't respond to having worn parts replaced.

We'll keep an eye on the tire wear and I will check the tie rod

ends and ball joints next year to see how they're doing. I am

hoping that with some regular lubing, they will last for a long

while.

As I said, I have read a lot about others' experiences with the

wobble and have read some horror stories of thousands of dollars

being spent and the wobble still remains. Since I haven't been

able to see these trucks, I have to take these stories at face

value. Maybe we just got lucky or maybe the guys working on

these trucks missed something. I don't know. What I do know is

that we tried to approach this repair in a methodical manner and

not just throw parts at it. We found some worn parts, replaced

them, and the wobble went away. I wish it was always this easy.

I also hope that if you are reading this article with hopes of

fixing your wobble, that you have the same outcome as we did.

© Fager October 30, 2014