Rebuilding

a

Deere

33

Tiller

-

part

3

September 26, 2012

Slipper Clutch

When I disassembled the slipper clutch, I found that the outboard

clutch disk was in bad shape. The inner hole was egg shaped and it

appeared that the disk had not been aligned on whatever kept it

centered in the clutch pack. I figured that it might have been

assembled wrong, but put off judgment until I had the time to focus on

it. Now was the time.

|

|

Fresh from

the solvent tank. You can see the egg-shaped hole in the one

clutch disk.

|

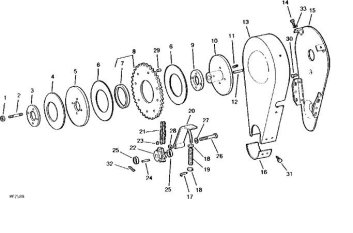

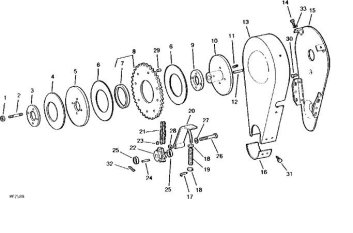

The Deere

parts diagram for the clutch assembly. The bushing in question is part

#7.

|

The slipper clutch is a pretty simple device. It is designed to allow

the sprocket (#8) to slip between the clutch disks (2 pieces shown as

#6)

if the tines should stop due to hitting a large root or rock. I

purchased a pair of new disks from Deere and after cleaning the clutch

pack, I assembled the clutch so I could see why the outboard disk

inside hole had been worn away.

What I found surprised me. The bushing (#7) that the sprocket rides on

didn't seem to be wide enough to support both the sprocket and the

clutch disks. The clutch pack is assembled as follows: The support

plate (#10) has a collar (#9) that centers the bushing (#7) which has a

thickness of about 0.320". The first clutch disk which is about

1/8" thick fits over the bushing. This leaves another 3/16" of the

bushing to mount the sprocket on - meaning that the bushing only comes

a little more than

half-way through the sprocket. Once you add the second clutch disk,

there is no bushing protruding to support the inner hole of the clutch

disk. Of course it is going to flop around since it's not

supported.

My question was what could have possibly happened that would cause

this. I wouldn't have expected the engineers at Deere to design it this

way. The clutch disks (part number M43389) are now listed the same for

all models.

However I have a very early tiller - serial 2549 - and the rear clutch

plate (#10 - hub) mounts on a 3/4" shaft. After serial number 8628, the

shaft size was increased to 1". From the JD parts listing, the

collar (#9 - bushing) doesn't change after serial 8628, so it appears

that they just reamed the hole from 3/4" to 1" without changing the

outer dimensions. The bushing that the sprocket rides on does

change, but not until serial 488001. Even if the bushing was made to be

thicker at that point, would Deere have shipped almost a half million

tillers with the outer clutch disk left unsupported? That seems a

little hard to believe.

|

|

With the

rear clutch disk and sprocket installed, the bronze bushing doesn't

even reach to the top if the sprocket inner hole.

|

As you can

see, the bronze bushing isn't tall enough to support the outboard

clutch disk. The disk is free to flop around. Very strange.

|

I did some more thinking

on the issue. Another possibility was that if

the bushing was a press fit on the sprocket and evenly centered, there'd be 0.027" of

bushing on either side of the sprocket to support the pair of

disks. I wouldn't think that would be enough bushing to support

the disks, but perhaps I am wrong. Oh well, I've done enough

speculation on what might have happened. At this point, my issue

was

what could I do to fix it?

What I decided to do was

to machine a new bushing that was thick enough to support both clutch

disks and the sprocket. The new question was how thick to make the

bushing.

If I made the thickness equal to the thickness of the two clutch disks

and the sprocket, as soon as the disks wore even a slight amount, the

disks

would slip between the two hubs (#5, #10). That wouldn't do. I decided

on making the bushing thick enough to support the inner clutch disk,

the sprocket and a portion of the way through the outer clutch disk.

That

should

allow for each clutch disk to wear a bit

before I would have trouble with the sprocket slipping due to the

bushing's interference.

To make a new bushing, I

decided to use some aluminum that I had on hand. Bronze/Oilite

would

wear better, but I didn't have any bronze large enough and there really

shouldn't be much wear on the bushing unless I am trying to till a

boulder field - hopefully that's something that I will try to stay away

from.

|

|

To make the

bushing, I started by boring the center hole to 3.006" and facing the

front side flat.

|

Action shot.

Making the last facing cut on the new aluminum bushing.

|

I

chucked up some 6061 aluminum scrap and bored a hole to 3.006".

The original bushing's inside diameter measured 3.010" and it was a

little loose on the 3" collar (#9 bush), so I reduced the diameter a

bit. I then faced the side of the bushing

flat. I changed chucks to one that could grip the inside diameter

and turned the outside diameter to 3.495". The O.D. of the

original bushing was 3.490". This would be a close

slip-fit on the 3.5" bore of the sprocket and clutch disks. I

then faced the other side until I reduced the thickness of the bushing

to 0.495". This would give me 0.075" of wear on the total

thickness of the two clutch disks before the bushing would interfere

with

clamping action of the slipper clutch. The combined thickness of both

disks and sprocket was

0.570". The sprocket thickness was

0.320" and each clutch disk was 0.125". If I find that the clutch disks

wear quickly and they end up slipping, I can always reduce the

thickness of the bushing to compensate for the wear. Accessing

the clutch pack is a pretty simple job.

|

|

You can see

the difference in thickness between the new aluminum bushing and the

stock bronze one. The rear collar is also shown.

|

If you

enlarge the image, you'll see that there is now just a slight step

between the height of the disk and the new bushing. No more floppy

clutch disk.

|

Once I had the new bushing machined, I compared the parts, then

assembled the clutch pack on the bench. I measured the difference in

height between the bushing and the top face of the outboard clutch

disk. It was very close to my projected 0.075" estimate. Good

deal.

Update: While re-reading

through the original manual that was shipped with the tiller, I came

across a picture that seems to allude to the fact that the bushing was

press fit into the sprocket. The sprocket is shown with the bushing

installed and not as a separate part as it appears in the JD parts

picture. Just enough bushing protrudes from the sprocket to center both

clutch disks. While I didn't see any wear on the outer diameter

of the the original Oilite bushing and the inner bore of the sprocket

didn't appear to be polished from the bushing spinning in the sprocket,

it is still possible that the bushing was a light press fit in the

sprocket. This new information does not change my mind about my

repair. In the worst case scenario I may have to reduce the

thickness of my new bushing some time in the future to make up for

clutch disk wear, but I will take that chance.

|

|

The slipper

clutch is installed along with a new #50 chain and my Delrin faced

tensioner.

|

The saw

blade points to the nut that I needed to loosen in order to get the

chain cover installed.

|

I had purchased some new #50 drive chain in a 10 foot length. I counted

out 59 links and cut the chain. 59 links plus the removable half-link

gave me the requisite 60 links. I added the tiller mount and

bolted on the angle drive. I threaded the new chain around my repaired

and Delrin faced chain tensioner and gave the chain a spin. It

appears that the repaired tensioner is going to work out just fine.

Hopefully

the Delrin doesn't wear too quickly.

Installing the chain cover wasn't as easy as I thought it would

be. The shape of the cover prevents it from being slid on from

above and there isn't enough space to get the narrow (bottom) end of

the cover past the rectangular section of the angle drive and on to the

cylindrical snout that leads to the gear. The manual doesn't

cover this at all. It just says to remove and replace the cover.

I ended up loosening the large nut on the back side of the inner cover

and pushing the back side of the cover away from the direction of the

angle drive. This gave me just enough room to pry the front cover

into place. I cut down some 1/4"-20 screws so that the threaded portion

was about 3/8" and used these to hold the cover in place. There's

a hidden screw between the cover and the tiller body. It was replaced

with a shortened bolt as there is no way to

get a screwdriver between the cover and tiller body, but there's plenty

of room for a wrench.

As I said early on, I broke the bar that sets the width for the tractor

mount section of the tiller. I had initially thought I would bend

up a new one using some 1/2" bar stock. I finally decided that

there was an easier way to go. I shortened the bar enough that I

could add in a 1/2"-13 coupling nut, then cut some new threads on the

end of the bar and added another

piece of threaded rod to the other end of the coupling nut. While

it looks

like a repair, it will work fine and that's what I am after.

|

|

After a bit

of fighting, I was able to get the outboard chain cover in place.

|

The spreader

bar broke at the beginning of the threads. I cut another section out,

then added threads to the end for the coupling nut.

|

When I tried moving the lever that engages and disengages the idler

pulley,

I found that I couldn't move the lever into the engage detent without

the idler pulley hitting the main drive sheaves. There is a

spring assist to keep tension on the belt and a locking collar to limit

the travel of the idler pulley. Of course the set screw on the

locking collar was frozen and I had to remove the assembly to the bench

to get a better grip on it so that the set screw could be removed. Once

I removed the screw, I cleaned up the shaft, gave it another coat of

paint and reinstalled it. I adjusted it so that the idler stopped a

little further from the main sheaves. I left the nuts that adjust

the spring tension finger tight so I can set the tension once the belts

are installed.

|

|

The idler

pulley adjustment collar is set so that the pulley doesn't hit the main

belt sheaves.

|

I still need

to fabricate some flaps that will cover the extension tines. I am

thinking of making these from 16 gauge sheet steel.

|

I am pretty much finished with the tiller. At some point, I need

to make a couple flaps for the rear end of the extension housings, but

I may use the tiller without these parts for now. The weather is

turning cold and I am running out of time. I want to till a

sodded area for a much larger garden so it can decompose a bit over the

winter and I still need

to design and fabricate a PTO shaft and double sheave to power the

tiller.

After some reading, I have also decided to run the tiller without the

oval end plates installed. The end plates make it more difficult

for the tiller to dig as deep as it would without using the

plates. It would seem that the purpose of the end plates is to

prevent your plants from getting sucked into the tiller when

cultivating between rows. That won't be an issue for me at this

time. I also may need to remove one or both of the extensions for

tilling this new patch of land. I do plan to plow before I till, but

the soil is pretty heavy with clay and I don't know if the tiller will

be able to handle the hard clay and sod with both extensions in place.

I guess I will find out soon enough.

I still need to make all of the final adjustments on the tiller. I

can't do that until I have it up and running. I set the depth

control bolts to the middle position and will adjust them up or down

depending on how well it tills in this position.

Hopefully I will get this all done in the next couple weeks.

© Fager 9-22-12