Rebuilding

a

Deere

33

Tiller

-

part

4

October 7, 2012

PTO

I purchased a used hydro fan to use as the end of the belt driven PTO.

I wanted to make sure that if I somehow screwed up building the new PTO

that I'd still be able to use the tractor.

Having bought the fan, I'll probably never need it, but if I didn't buy

it, I probably would. This is my corollary to Murphy's law.

I machined a piece of 2"

round steel to fit the shape of the fan end. I then drilled and tapped

the fan end to accept a 5/16" - 18 allen bolt. This would not only

locate the 2" round on the end of the fan, but also add a little

strength to the assembly after the extra piece was welded to the

end. After trying different amperage settings on the arc welder

on some similarly sized scrap pieces, I found that I couldn't come to a

happy medium in regard to amperage settings. Too low and I could weld

the 1/8" fan blades, but didn't get good penetration on the 2" round.

Too high and I got good penetration on the heavy stock, but burned

through the 1/8". Rather than chance ruining the fan, I decided to

braze it where I have better control of how much and where I focus the

heat. The job doesn't look that pretty, but the weld seems to take as

much punishment as I could easily give it without bending the blades -

and that was without the allen bolt installed. With the bolt installed

it should be able to handle the rotational stress - or at least I hope

so. We'll see how it holds up over time.

|

|

Trying out

the hydro fan with extension welded on.

|

An internal

square was cut in the extension to match the square milled in the 3/4"

bar.

|

The next step was to build the bracket that holds the shaft parallel to

the hydro output shaft/fan. I used some 1/4" sheet steel cut to the

approximate size. I drilled a couple holes to line up with the bolts

that hold the rear hydraulic port bracket. I used an L square to line

up where I thought that the hole for the 3/4" PTO shaft should go and

drilled it to 3/4". This would allow me to see if the alignment between

the bracket and hydro was good before I enlarged the hole for the 1

1/4" ID bearing I would use. While studying pictures of the stock PTOs

I noticed that they all had a collar that was much larger than the

shaft where it passed through the bearing. I assumed that this was done

to be able to use a larger bearing. A bearing with an ID of 1.25"

should be able to take more abuse than one with an ID of 0.75". I

am hoping that my PTO will still be functional in 20 years.

|

|

I did a test

fit of the bracket so I could mark where to cut the top of the bracket.

|

I set the

bracket back up on the mill, located the hole and bored the hole out to

1.7" with a fly cutter.

|

With the holes drilled, I mounted up the bracket and checked the

alignment. It wasn't more than about 0.010" high. Pretty good for

"eyeballing" it. I used a 7/8" end mill to move the hole up a bit, then

rechecked the alignment by wrapping the shaft with some lead shim stock

to make up the difference between the 3/4" shaft and 7/8" hole. This

time it checked out to be within a couple thousandths of an inch.

Close enough for this job. With the hole now aligned, I used a fly

cutter to open the hole up to 1.7". This will allow the collar on the

PTO shaft to fit through the bracket and rest on the inboard side of

the bearing.

|

|

There's now

plenty of room for the PTO shaft and collar that will set the depth of

the shaft in the hydro fan. The cut-out is for the right rear hydraulic

coupler

|

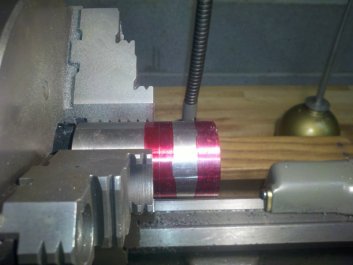

Some drill

rod is chucked up in the lathe to make the collar bushing.

|

Since I was using a bearing with an inside diameter of 1.25 and a 3/4"

shaft, I needed to make a bushing/collar to get the shaft to fit the

bearing. I used some 1 1/2" O2 drill rod and faced one end flat.

I scribed lines for the 1.25" diameter section to be 1.5" long and the

total length of 2.5". I drilled through the bushing, then reamed it to

.75". I was looking for and ended up with a tight sliding fit between

the bushing and shaft. I then turned down the inch and a half section

to 1.24" so that the bushing would have a tight sliding fit in the

bearing.

|

|

The diameter

of the chucked end is just under 1.5" - diameter is not critical - and

the other end has been turned

to 1.24". This side needs to be close.

|

Everything

fits as it should. I still need to add a set screw to the large end of

the collar so it can be locked in place.

|

Before I drilled the holes to mount the bearing to the bracket, I

decided to install

the gas tank and make

sure that I didn't have any clearance issues. It was a good thing

that I did. My bracket was about 3/4" too wide on either side. I marked

the bracket and did some cutting and milling to fix the issue.

With the clearance issues fixed, I moved on to the next issue.

|

|

Houston, we

have a problem. I needed to do a little cutting to gain some clearance

around the bracket

|

Studs are

tack welded in place on the back of the mounting strap.

|

I wanted to be able to

remove the PTO when it wasn't needed. I had made

the shaft so it could slip in and out, but the bolts that hold the

brackets in place could only be accessed if the fender pan and gas tank

were removed. What I needed were some fixed studs that protruded

rearward so I just needed to remove and replace a couple nuts to mount

the PTO bracket.

I cut a piece of 3/16" sheet steel to four inches and drilled and

tapped a couple

holes for 3/8" - 16 threads. These were drilled three inches apart. I

cut some threaded rod to 1 1/4" lengths and then secured

the studs with a tack weld. I also drilled a 1/4" hole mid-way in the

strap to allow me to secure the strap to the inside of the sheet metal

bracket that holds the rear hydraulic ports.

|

|

Business

side of the stud bracket.

Two 1.25" studs 3" on center.

|

I used a

sheet metal screw to hold the stud bracket in place. Simple and

effective.

|

I don't know how Deere secured the PTO without requiring you to remove

the fender pan and gas tank on the 317, but this little stud bracket

works great. I've had the PTO bracket on and off a few dozen

times and having to just remove two nuts is a lot easier than having to

use a wrench and socket on a loose nut and bolt.

|

|

|

The stud

bracket is installed.

|

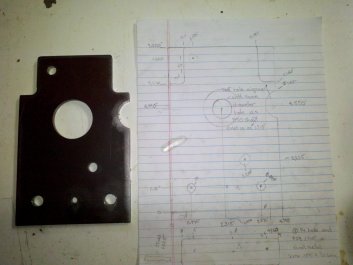

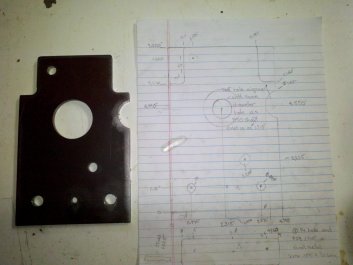

The finished

PTO bracket along with my fabrication notes.

|

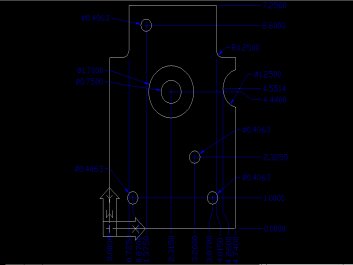

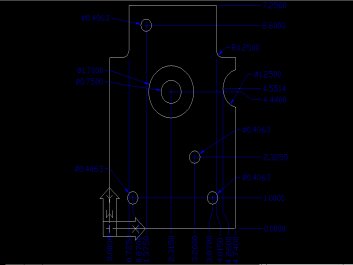

The CAD

drawing in JPG format. Click image for full size or here for the AutoCAD DWG file.

|

With the bracket installed I marked the two holes that would locate the

bearing (UCFL206-20)

on

the

PTO

bracket.

I

drilled

some

13/32"

holes

to

just

clear

the 3/8"

- 16 bolts that would be used to hold the bearing in place. I also

drilled and tapped the collar/bushing for a 1/4" - 20 x 1/2" set screw

to keep the shaft from sliding out of the hydro fan. Once I determined

the correct spot, I milled a small flat on the shaft for the set screw

to press against. Since all I had were 3/4" long set screws, I

used a allen screw for the present time. I have a few bolts and set

screws that need to be purchased before I try using the PTO.

|

|

The PTO is

about finished. All that remains is to make a double sheave to

power the tiller.

|

The inner

bushing/collar screw sets the depth of the PTO shaft in the hydro fan.

|

Pulley/Sheave

My Canadian friend, Kevin, supplied me with the dimensions for the

double sheave that powers the tiller. I looked around for a 3 5/8" OD

double pulley for 1/2" belts for a few weeks or so without finding one

that was suitable for this application. Deere lists the price for

this pulley at about $80 and I thought that this was a bit much, so I

decided to make my own. All I needed to do was turn two half inch

grooves to fit the shape of the 1/2" wide x 5/16" deep belts and space

them 3/16" apart. How hard could that be?

As I have never machined a sheave from scratch before, I did a little

research on sheaves and pulleys. It turns out the even though the

v-belt included angle is 40°, when machining a drive pulley, the

angle of the sides of the groove should be machined to a lesser

included angle. This is done so that the wedging action as the

belt is stretched causes more gripping force between the pulley and the

belt. Drive pulleys are generally smaller than driven pulleys and the

machined angle differs depending on their use. It is said that 32°

to 34° for drive pulleys and 36° to 38° for driven pulleys

are the optimum angles for "A" type or 4L belts.

The depth of the groove is also cut deeper than the depth of the belt.

The depth of the groove should be deep enough that even when the belt

is stretched or worn it will not contact the bottom of the

groove. I will machine the depth to about 0.45".

Although aluminum is not the ideal material for a pulley, I chose it

because I have a good assortment of aluminum rounds. That said, I

had an aluminum fan pulley on an old Volkswagen that didn't visibly

wear

for many years and this pulley will only see use a couple times a year.

The closest chunk of aluminum

round I had was 4.5" diameter by 2.25" thick. Almost perfect on the

thickness. The double sheaves and space between them worked out to be

about 1.3" and I wanted somewhere between 3/4" -1" length for the

reduced diameter "snout" that would attach the pulley to the shaft with

a couple of set screws.

I started by chucking up the aluminum and facing the one side. Now the

width was 2.2". I now needed to turn the diameter of the snout from

4.5" to 2". This would result in a lot of wasted aluminum, so I decided

to cut a ring out of the chunk of round. No telling when a ring with an

OD of 4.5" and an ID of 2+" would be useful for another project. I used

a parting tool to cut a slot in the round and then came in from the

face side to separate the ring from the chunk.

|

|

Using a

parting tool to cut in 2.5". It's a deep cut on a small lathe, so I

advanced the bit slowly.

|

After

grinding a thin bit, I cut in from the side until the two cuts met.

Results: one ring of aluminum saved for a future project.

|

The pulley was drilled for

the 3/4" shaft and then I tried something that I had only read about -

making a key-way slot on a lathe. I used a very sharp parting

tool

and with the lathe off, I used the carriage crank to advance the tool

into the hole. Each

pass was only removed a thousandth or so of material. Very slow going

and there was a fair amount of deflection. This meant that the key-way

was deeper toward the entry side than the rear. I would even out the

depth when I

finished cutting the pulley grooves as I didn't want to un-chuck the

pulley until all of the cuts were made.

|

|

With the

round of aluminum now chucked by the snout, I started reducing the

diameter.

|

I measured

and marked the lines I would use for reference. These match the pulley

on the tiller.

|

I next cut a relief on the rear side of the pulley. This would allow me

to move the pulley a bit closer toward the PTO bearing to set the belt

alignment. In hind-sight, a bearing with a slightly shorter inner race

would have not required the relief to be cut in the pulley. On the plus

side, the closer the pulley is to the bearing, the less leverage force

that will be exerted on it.

To cut the groves, I measured and marked the lines I would cut to. I

ground a bit with each side angled to 16°. I started in the center

of each area I had marked for the groove and by advancing the bit 10

thousandths for each pass, I cut the grooves. I finished the job with

some crocus cloth to round over the corners of each groove so that the

belt would not get cut.

|

|

Using a bit

ground to 16° on each side, I started cutting the grooves.

|

First groove

done and starting on the second.

|

When I was done with the grooves, I removed the pulley from the lathe

and used a file to even out the key-way.

The next step was to cut a key-way in the PTO shaft. This was done with

an end mill on the milling machine. I then cut a key from some mild

steel stock and spent the rest of the evening filing and adjusting

until the pulley, key and shaft all fit together nicely.

|

|

The grooves

have been cut and the edges have been smoothed with some crocus cloth.

|

Test fitting

the pulley on the PTO shaft. Everything aligns as it should. Looks like

I'll need some new belts as these don't seem to be a matched pair.

|

I had a couple choices for holding the pulley on the shaft. I could

drill and tap the end of the shaft for bolt that would run parallel to

the shaft or use set screws at a right angle to the shaft. Due to not

having a shoulder on the shaft to clamp to, I decided on using set

screws. I drilled and tapped the pulley for two 1/4"-20 x 3/4" set

screws over the top of the key and two more offset 90°.

Probably a bit of over-kill, but I'm betting that the pulley doesn't

come loose from the shaft.

Last thing on the PTO agenda was to give the PTO bracket a coat of

gloss black paint. That done, I assembled the PTO and bolted it

in place. I have to say that installing this PTO is as easy as

installing any other of the Deere accessories I have.

|

|

Two pair of

set screws. Two over the key and two at ninety degrees. Over-kill, but

what the heck.

|

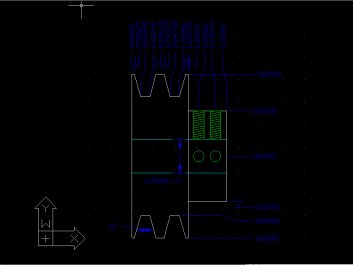

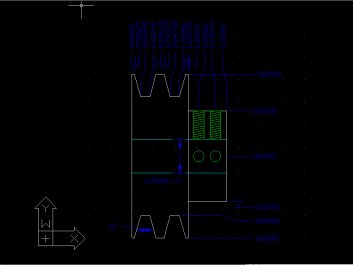

Drawing for

PTO double sheave. Click image for larger view or here for DWG file.

|

October 12, 2012

I put the gas tank back on tonight and fired up the 317. With the idler

pulley disengaged, the tiller tines turn slowly. Unfortunately this is

normal for an idler pulley clutch. You could probably

stop them from turning by putting the tines into the earth, but I sure

wouldn't want to try and stop them with my hands. I pulled on the

hydraulic lever to raise the tiller off the blocks I had it positioned

on and engaged the idler. It's alive!

The tiller is really quiet.

Just the whirring of the chains and tines. Sounds really good. The rear

belt was flapping as it's a bit longer than the front one. Both belts

are in pretty sorry shape. I have to get some new belts ordered,

but hopefully the old ones will last long enough to try the tiller out

tomorrow. I'd like to know that I assembled everything correctly and

that I don't need to strip it down to fix some problem or another.

The tiller

came with a link rod that was meant for a 140. It appears that

Deere added a transmission mount on the 317 (300 series) that

interferes with the straight link

that the 140 used. Kind of strange that the mount wasn't designed so

that the same link could be used as it is very close to fitting without

interference. The link rod

that I built for my sleeve hitch will work to raise and lower the

tiller, but it lacks the depth

adjustment cam for locking the tiller into the desired position.

It does appear that one could notch the 140 link rod and make

it clear the trans mount, but you'd need to strengthen the area of the

notch. I

will have to give this a little more thought. Tomorrow I'll give

the tiller a road test and see how it performs.

October 13, 2012

I decided not to try and run the tiller using the link rod that I use

for my sleeve hitch. If I used it, there is no way to lock the tiller

all of the way up in the transport position. The cylinder that

controls the rock shaft does leak down a bit and I didn't want to

chance the tiller hitting the ground as I drove out to the area I am

going to till. My choices now were to either notch the 140 link rod or

fabricate a new one. I guess I could also wait for a 300 series link

rod to show up somewhere, but the chances that I'd find one before the

weather gets too cold are probably slim.

I decided that I would cut a notch out of the straight 140 link arm so

that would clear the transmission mount. This would reduce the amount

of metal in the rod by half, but seeing as there are two 3/16" pieces

of steel strap welded together, it should be strong enough to test the

tiller. Once I test the tiller operation, I will weld in a section to

strengthen the rod and still clear the transmission mount.

With the modified link rod in place, I could now use the depth

adjusting cam. I raised the tiller and locked the cam into the

transport position and rode out to the new garden area. I readjusted

the cam and set the depth for about 2 inches. I fired the 317 back up

and engaged the tiller. As I lowered the tiller into the soil, it

pushed the tractor forward a couple inches while chewing through the

short grass, weeds and soil. I slowly drove forward about 20 yards and

stopped to examine my work. The ground was nicely shredded with the

bits of sod and roots sitting on top of the soil. I didn't hear any bad

noises coming from the tiller and all of the tines were where they had

been welded. So far, so good. Another couple passes and I

checked the tiller over again. Still good. I ended up tilling a section

about 70 feet by 25 feet before one of the belts flipped off. I was

expecting this but at least I was able to test out the tiller and it

passed with flying colors.

|

|

Back in the

shop and the tiller has broken some ground - as well as shredded some

belts.

|

Long shadows

show it's late in the day, but we now have a part of the new garden

tilled.

|

In the tiller manual, I had read that when using both extensions one

should not try to till full depth in one pass. As I learn what the

tiller is capable of, I will error on the side of caution and try not

to stress it too much. I am trying to till fairly hard packed

clay sod that has not been broken in at least 20 years (and maybe

never) so being cautious is probably the best way to approach this job.

As I said, I need to order a pair of belts for the tiller.

Depending on the PTO style, Deere lists two: AM32172 and AM32636.

From what I can tell, the former is for the earliest solid-shaft PTOs

and the latter for the rest. The AM32172 has a length of 35.4 and the

AM32636 has a length of 35.76. In the belt cross-references I looked

at, they both supersede to a 4L-350 belt. Seeing as how my PTO is

shop made, I'm not sure that three and a half tenths of an inch are

going to matter. In the past, I have purchased all of my Deere belts

from Deere. However, I can get two 4L-350 belts for $11 delivered in a

day from McMaster.com and Deere wants $40. I'm all for supporting my

local Deere dealer, but not this time. We'll see how it goes.

|

|

I think that

the PTO pulley looks pretty good peeking out from the fender pan.

|

New

attachment stud bushing on the bolt and the old ones above it.

|

October 18, 2012

The belts arrived yesterday. As you'd deduce from the number, they were

35". So they're between a half or three quarters of an inch shorter

than either of the Deere belts. They were a bit tough to get over the

pulley and I ended up using the old mechanic's trick of using the

starter to bump them on. However before I could put them on I had to

deal with something I had forgotten to do.

The attachment studs that hold the bottom tiller mount to the bracket

were too short. The existing studs had a 0.320" wide bushing. This fit

the sleeve hitch perfectly, but the tiller mount was a little more than

1/2" wide. To test the tiller, I had just loosened the studs, but

there's no way I would run it like that for more than a test. The

stud bushings are .75" OD and .5" ID. I used some 1" drill rod to

make the new bushings on the lathe. Outside diameter was 0.75"

with an 0.5" hole and 0.550" in length. I

re-used the original bolts. I used a zip tie to attach the old bushings

to the sleeve hitch so I wouldn't lose them.

|

|

The new

belts are in a lot better shape than the old ones. You can see the

modified position of the coupler on the spreader bar.

|

It was a bit

of a fight to get the new belts over the pulley but they work great.

The tension is set and the two belts seem to be exactly the same size.

|

In my test I had also found that the coupling nut I used to fix the

spreader bar was in exactly the wrong spot. It rubbed against the depth

adjuster cam and made setting the depth tough. I cut the spreader bar a

bit shorter and re-threaded it so that the coupler was moved to the

left a couple inches. By this time it was getting late. No trying

out the new belts tonight.

Late this afternoon I finally got a chance to run the tiller with

everything fixed. I'm impressed with how well it works. I

set the depth to about 4 inches and tilled the area I had tilled the

other day. I then went back over it at full depth. It did a real nice

job of cutting up the sod and mixing it in with the soil.

Tomorrow I will work some compost into the soil and let it be until

spring.

|

|

The depth

adjustment cam now has plenty of clearance from the spreader bar.

|

Blurry

picture, but the tiller has done a great job of breaking up the sod and

mixing it into the soil.

|

This tiller has not been the quickest or easiest repair/restoration job

I have done, but seeing the tiller produce fluffy soil from the hard

packed sod has made the journey well worth the time and money spent. As

I hope will always be the case, I learned a few new things and got to

use some tools. I can't ask for much more than that.

If you have questions or comments, drop me an email.

© Fager 10-07-12