|

|

|

|

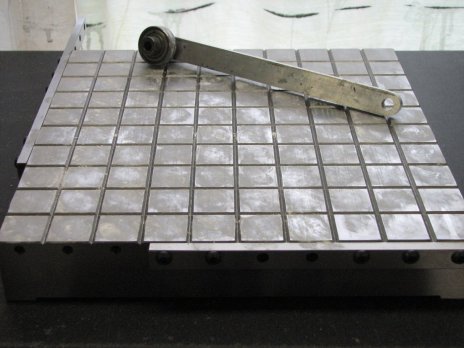

| With a ball bearing roller to

apply the 3000 mesh diamond powder, I rolled it in as evenly as I

could. I then did a practice run on my carefully mapped old

surface plate. I then reapplied more diamond powder and carefully

lapped the top of the granite straight edge. After checking level

in front and behind the straight edge, I checked the top surface of the

straight edge. After a couple cycles, it was level and smooth.

|

After a few passes on the top surface of the straight edge, I set up my

measuring gear so I could check the relative height of the top

surface. This turned out to be as close to zero difference in

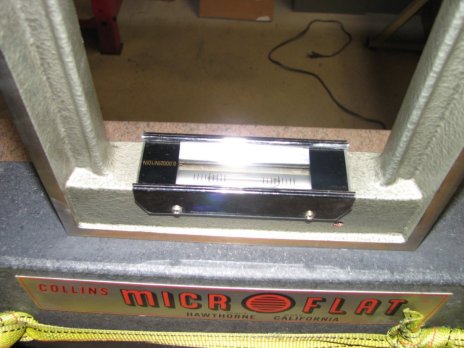

height as I can measure. For the last check, I leveled my new

Starrett surface plate with the straight edge centered on it.

When I had the bubble centered on my 0.0002" per 10" box level while on

both sides of the straight edge, I placed the level on the top

surface of the straight edge. In this position, the level also

centered the bubble. This was no surprise since the Supramess

indicator that I used to measure the relative height of the top surface

has much better resolution (20 millionths) than the level, but I was

happy for the confirmation none-the-less.

So, one more mini-project is done and I now have a way to check level

between the separated ways of the surface grinder. This should

help me to make sure that both the saddle and table on the surface

grinder stay level and square with the vertical column. As a part

of the project, I have now acquired a lap that I will use only for 3000

mesh diamonds. The 3000 mesh diamonds leave a pretty nice finish

on granite, but it would be nice to have one more lap that I can devote

to 5000 mesh only for situations where I would prefer an even finer

finish.