|

Shumatech

DRO-350 Repairs

July 4,

2009

When I

purchased my DRO back in 2006, I also purchased a spare. I was

planning on putting it on a lathe, when one arrived. I built and

tested the second PC board, but never got around to installing it

on the lathe. Fast forward to May 2009 when I purchased two more

Jenix scales for the mill. After three years of running the

Chinese scales on the Y and Z axes, I decided to go all glass

quadrature scales. The mill's current Y scale, which was a 6" HF

caliper had developed a bit of play in the gibs and needed to be tapped

a couple times to center it or it would read a couple thousandths of an

inch plus or minus the actual coordinate. I could have probably

pulled the scale apart and cleaned and lubed it, but I have grown fond

of the Jenix I'm running on the X axis and the fact that it is always

repeatable within its specifications. I consider the Jenix a step or

two up from the Chinese capacitance scales.

The DRO had developed one

problem in its display. The center segment (labeled "G" on the

display diagrams) of one

of the Z readouts had stopped illuminating. I planned to take

care of this while I set up the box to handle another two Jenix scales.

Once I got inside the DRO

and started tracking down the issue with the center segment, I found

that the "G" segment of DS8A had burned out. This proved to be a

bit more of a problem than I expected as the MAN6940 Seven Segment LED

Display is no longer a stocked item at my usual electronics

suppliers. I ended up ordering 10 replacements (630-HDSP-523E

from Mouser), in case I wasn't pleased with just replacing the one with

the problem. I figured I'd just pull out the other DRO-350 board

and swap it with the spare. This would give me plenty of time to

replace as many of the displays as I needed to get a nice looking read

out.

What I didn't count on is

that I would be careless and blow up the second board. Yep,

that's right, I plugged in the power plug to JP6 reversed. As

soon as I realized what I'd done, I knew that there would be

problems. There were. I now had missing segments on the X

display and nothing on the Y. Nothing. No r4 message

at boot up, no no read out from the scale. No nothing.

Well, that's not entirely true. If I jumped across the number 12

and 13 pins of U10, I got the decimal points to light up.

However, that doesn't tell me enough to fix it. Only the Z axis

showed what it was supposed to, "nnill."

|

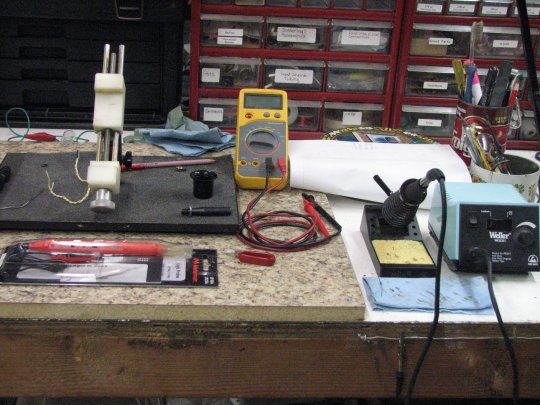

| Tools

used for the repairs. Digital volt/ohm meter, logic probe, circuit

board vise and soldering station. My anti-static strap hangs from the clip, on the right. |

I was in a heap of

trouble. I don't have a oscilloscope. All I have is a

decent DVOM and a

logic probe. The

one thing I had

going for me is that I had a working board to compare the blown one

to. That and all of the great posts by Lester and the rest of the

guys who really know the DRO-350 on the Shumatech Yahoo group. I

had also purchased extra of all the parts necessary to build the

DRO-350.

As I read through the

posts, I found that I wasn't the only person to try and repair a

DRO-350 without a scope. It seems that without a scope, it

makes the process of deducing whether a part is good or bad a bit

harder. Harder, yes. Impossible, no - and since I am sure

that I am not the only person to fry a board, I thought that sharing my

method of repairing mine might help someone else in a similar situation.

The first thing to know

about the display circuit is that each of the 3 LED displays

per axis is actually two displays. Each of the 6 displays (2 X 3) is

comprised of 8 anode segments (7 bars that make up the parts of the

number plus the dot) and a cathode.

Each segment is given a letter designation. Letter "a" is the top

horizontal bar, "g" is the center bar and "dp" is the dot. Pins 13 and

14 of each double digit display are the two cathodes. Aside from

the two cathodes which selectively complete the circuit though the

ULN2803A chips , each of the other 8 segments in each half of the

display are connected to every other same letter on the other 5 half

displays. This means that all Y axis "a" segments are on the same

circuit and you should be able to use your continuity tester to show a

completed circuit between all of the "a" segments. This would

include three number 11 pins and three number 16 pins of DS7A/B DS8 A/B

and DS9 A/B. If one pin lacks continuity, look for a broken trace

on the board or a bad solder joint.

Each segment is lit by a

circuit completed from the plus side (+9 volts) of the wall wart

flowing

ultimately through one of the 150 Ohm resistors in R12, R13 or R14,

then to the lettered segment, then out the cathode on pin 13 or

14 and returning to the minus (-) side of the wall wart. Between

the

resistors and the PIC, there are the display driving ICs that dictate

when the segment

will be lit. On the anode side, we start at the PIC microcontroller on

pins 11 through 18, then to the 2 through 9 pins of the

M74HC573B1R IC and out the opposite side on the 12 through 19 pins,

then

to input pins (1-8)UDN2983A and out through (9-16), then to the

resistor pack. If you look at the circuit

diagram, you'll see that the signal enters on one side and goes out

the opposite side - straight across the IC. Once you get to the

display units, you need to read the pin numbers on the schematic as the

representations of the displays are not sequentially numbered like the

ICs.

On the cathode side of

each display, the ending points are pins 13 and 14 of each half display

chip. Starting from the PIC on pins 5, 6, and 7, the signal goes

to the 1, 2, and 3 pins of the M74HC238B1R IC, then out on the 9 through 15

pins and on to the 1 through 7 pins of the ULN2803A and out the13

through 18 pins to complete the cathode circuit on pins 13 and 14 of

each display.

Confused? Trace it on the display and microprocessor circuit

diagrams

which

will make it easier to follow.

To add one more layer of

complexity to diagnosing the display, it is multiplexed. The data

0 through 7 lines carry the display data and the column 0 through 7

lines complete the circuit one column (each half display) at a

time. If I view the display through the viewfinder screen of my

digital camera, I can see each column of the X, Y, and Z displays light

brightly, one column in all three rows at a time, across the 6 columns

of the display and seventh column, the indicator LEDs. With each column

lighting for a fraction of a second, it tricks the eyes into seeing a

solidly lit display. Photos of the display sort of show this, but

at the shutter speed I was using, it shows as two columns bright and

the remainder a bit dimmer.

I started with the PC

board out of the box and held up so that the buttons would not get

pressed accidentally. The only thing plugged into the board is power at

JP6. Once plugged in, the boot message appears. In my case, only the

top and bottom lines were lit and the characters in the X display were

missing some segments. I left the boot up message on the screen and

began my tests.

I looked at the schematic

and found the VCC and grounds for each of the ICs and tested these with

a volt meter. With those are reading as they should, I grabbed my

logic probe and started at the number 11 pin of the PIC (Data0). I

checked it for a pulse. Good. Then on to pin 2 of U7, the M74HC573B1R

on the X axis of my mill display. This display was mostly working, but

missing the top center (a) segment all the way across the display. I

got a pulse at the 2 pin, but only a low logic signal with no pulse on

the output pin 19. This was telling me that I had at least one

bad circuit inside this IC and it needed to be replaced. I then

checked the input and output of U10. This is the same M74HC573B1R IC, but on the Y axis. Pin 2

showed a pulse, but pin 19 showed nothing. I checked it with the DVOM

and it was reading a couple microvolts. The Y display was

entirely

blank, so I wasn't surprised. On to the working Z display's M74HC573B1R IC. Pulsed input, pulsed output.

One of the three ICs checked out correctly, but this was only the first

pin check. With the information I now had, I knew that I had two

bad ICs, but I went ahead and checked each circuit from the PIC to the

output side of the 3 M74HC573B1R ICs. The remainder of the

pins on the X axis M74HC573B1R IC showed good. The IC on

the Y axis had 0 pin pairs that showed a pulse on both sides of the IC

and the IC on the Z axis showed all pins good with a pulse showing on

both the input and output side of the IC.

It really didn't make much

sense to trying and follow the circuits to their next step until I

fixed what I knew (or thought I knew) was wrong. To remove the

two ICs, I used a hobby knife with a newly sharpened #11 blade. I

placed the side of the blade flat against the IC with the sharp edge

between the first two pins of the IC. By rocking the knife

toward, then away from the pins, I used pin 2 as a fulcrum to cut pin

1. Then pin 3 as the fulcrum to cut pin 2. If I had a pair

of diagonal cutters small enough to fit between the pins, I could have

used those, but my smallest pair of cutters were too big for the

job. Once I had cut all but the two end pins from the IC, I

clipped the last pins with my diagonal cutters and removed the plastic

portion of the IC.

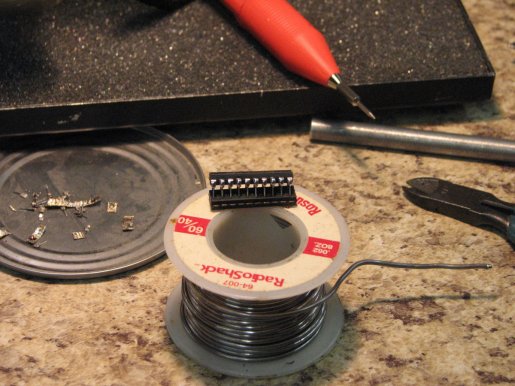

|

|

| The

leads for U10 have been clipped and the IC is ready to be removed. |

The new IC sits on top of the old IC. The new IC has its pins pretinned. |

I then used my soldering

iron and a pair of tweezers to remove the pins from the circuit

board. The next step was to use some rosin coated desoldering

braid to soak up most of the solder and clear the holes. The last

step was to wash the area off with isopropyl alcohol and dry it with my

heat gun. Soldering the new chips in was a bit tougher than it

was when the displays weren't on the board. I made this a bit

easier by tinning each of the legs of the IC before inserting it into

the board. I also left a little "blob" of solder at the top of

each leg so that a quick touch with the iron would melt it and flow

down the pin. I think this helped to get enough solder on to each

pin quickly and avoid overheating the IC. With some talk about

the possibility of the through-holes not being connected from top to

bottom, I wanted enough solder to solidly connect each pint to both the

top and bottom of the circuit board. Also, be wary of your

soldering iron tip. It is very easy to

touch the iron to the displays and produce melt marks. I

put a piece of aluminum duct tape over the sides of the displays to

help me avoid making a mess of the plastic. I ended up with only one

small burn that won't show when the case is back in place, so I

consider myself lucky.

I plugged power back into

the board. This time I had all displays working for the boot up

message. I was quite pleased with myself until I plugged in the

scales. The second from the right half display on the Y axis

(DS6A)

wasn't showing anything. Nuts! Looking at the schematic, it

appeared that the only thing that could cause this would be the U12

ULN2803A IC wasn't getting a ground to pin 14. I confirmed this

by checking the input #2 pin (pulsed) and output on pin #17 showing

nothing with the logic probe and microvolts with the DVOM.

I replaced the ULN2803A IC and rechecked the

display. Everything worked with my Chinese capacitance

scales. However, I could only check 2 of the axes at once as I

had been running a Jenix on the X and it was still on the mill on the

other side of the room. I did have a 12" Chinese caliper that I

could wire up, but I still wanted it to be able to be used as a

free-standing caliper. I decided to add a 0.1 µF and a 100

µF cap in the battery compartment, then add a MTA-100 4 pin

header to the scale's header. I'd then be able to plug either a

scale cable or battery in that spot. This would allow me to use

the caliper for testing a DRO or as a stand-alone caliper. Not a

big modification, but it works like a champ.

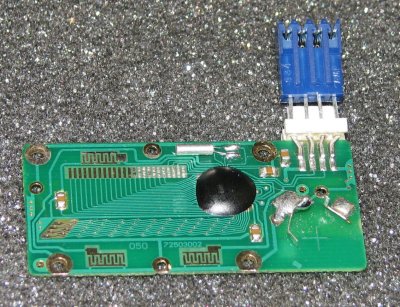

|

|

|

| Caliper

circuit board with MTA 4 pin connector attached. |

Battery

plugged in with a female MTA connector. |

Unplug the battery and plug in the scale cable |

I added the two additional

QCC-100 dongles and checked

again. Now I had the X and Y display working and no Z. Not

even a zero on the Z display. I swapped the QCC-100s and the

problem moved with the QCC. With the logic probe, I checked the

output pins at 6 and 7 on the little PIC. No pulse. I had

one extra PIC for

the QCC-100 and checked that on my PIC programmer. It checked good, so

I desoldered the old PIC and soldered in the new. 8 pins is about

the extent of my luck in getting an IC out in one piece without ruining

the pins or getting the IC too hot and killing it. Same

issue, no pulse and no readout on Z. After checking the traces

for the tenth time, I figured it had to be the oscillator, but no, the

two spares I had made no difference. I was getting a bit

frustrated, so I ordered a new QCC-100 kit. When it came after a

few days, I had been thinking about the problem and reading the posts

on the Shumatech Yahoo group. I believe it was Lester who had

stated that he had gotten a bad batch of oscillators. I was now

pretty sure that this was my problem too. I tried

the newly purchased oscillator in my broken QCC-100.

Success. It turned out

that over half of the oscillators I had purchased a few years ago must

have been

bad. What are the chances of getting 3 bad ones in a row?

Probably about as good as winning the lottery. I've looked

carefully at the parts and they look fine. I guess it might be

possible that they were mis-marked, but whatever the reason, it is not

the type of thing that one would expect.

I now had my spare DRO

working, but I still needed to fix the one bad display on the DRO on my

mill. I decided that I needed the DRO working now, so I ended up

swapping the repaired board into the old

case. I had purchased the extra Jenix connectors so that I could

plug

the Jenix cables straight into the DRO and spent some time adding the

QCC-100 circuit boards inside the DRO case. Once I had this done,

I needed to decide whether I would try to run the 3 Jenix scales from

the 5 volt voltage regulator on the DRO-350 or add a regulated 5 volt

wall wart to power the scales. I re-read Scott's post on the

situation and decided

that since I was using a 9 volt regulated wall wart for power, I would

probably be safe with running everything off the one power

supply. Just to be on the safe side, I milled up a large heat

sink that would attach between the two regulators on the circuit

board. On the side of the U17, the regulator that supplies the

1.5 volts, I made a thin plastic insulator and used a nylon 4-40 bolt

to attach the heat sink. On the side of the 5 volt regulator, I

added some good heat sink paste and a metal 4-40 bolt. This is a

really big chunk of aluminum and it soaks up a lot of heat. As

you have probably figured out from my description, the idea was to not

have the bases of these two regulators be joined electrically.

Had they both been single voltage regulators with grounded bases, it

would have not mattered, but U17 is an adjustable regulator and

grounding the base in this circuit would have been bad. As it

turned out, the big heat sink seems to work well and after a full day

in the shop with the DRO on, the side of the case isn't even

warm.

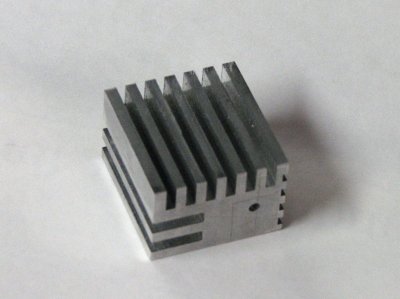

|

|

| A

healthy block of aluminum makes a good heat sink. |

Heat

sink, QCC-100s, and the Jenix connectors just fit. |

I spent a couple days

working

on the mounts for the Jenix scales.

I planned to keep the locations of the new scales in the same places as

the old ones, but both mounts were going to require new holders

fabricated as I chose an 8 inch scale for the Y. An 8 inch Jenix

is actually 14 inches long. This is about twice the length of the

capacitive scale it was replacing. The extra length would come

very close to the end of the knee, so I needed to shim the scale a

little further out so it

wouldn't interfere with the body of the mill. It turned out that

I only needed about an extra fraction of an inch, so the scale's mount

is

still very robust. I used a 0.25" thick by 1.00" wide length of

6061 aluminum flat stock as a mount for the scale. The holes at

each end of the scales are slotted so that I could tweak the scale to

be parallel with the knee ways.

The Z scale was a bit

harder to mount. The side of the mill column is angled at about

3°,

so I had to take this into consideration when building the mount.

I initially made up a piece of 18 gauge sheet metal as the connector

between the scale head and knee. I used gage blocks between

the sheet metal and scale to check that the scale was as parallel to

the Z ways as possible. I used shim stock to achieve parallelism

and then pulled the mounts and used a sine table and gage blocks to

measure the length and angle of each mount. Once I was happy with

the measurements, I milled the mounts. I bolted everything back

together using the sheet metal as the connector and rechecked the scale

head to make sure that it ran parallel to the scale. Once I was

satisfied, I used the same 0.25" thick aluminum

plate I had used elsewhere to make the connector between the head and

the knee. There is no flex or deviation from parallel that I can

measure.

|

|

|

|

| Jenix

scale on the Y axis is a tight fit. |

At

about 14" long it spans the whole knee. |

The Z

axis mount keeps the swarf away. |

The

armored cables are cut to length. |

One last consideration for

the Z axis scale mount was that the open side of the scale needed to

face away from the flying swarf. While I do have a rubber guard

that keeps the chips away from the Z ways and extends far enough out on

either side of the ways to prevent a lot of metal from flying in the

direction of the scale, it won't catch all of the chips. Due to

the way the head was mounted to the scale and that I needed the cable

to exit toward the top of the mill, I would need to mount the scale

with the front side facing the mill's body. I considered taking

the scale apart and seeing if I could reverse the direction of the

head, but decided that I didn't want to take a new scale apart. I

built the mounts to conform to the plastic end caps on the scale and it

seems to work just fine. To keep the armored cable from flopping

around, I cut a disk from sheet metal and mounted it on the lamp

mount. I also added an angle adapter to the lamp base to fix the

bothersome way the lamp was originally mounted. Both the angle

adapter and the disk worked out quite well. The weight of the

armored cable keeps it tidy and the lamp no longer gets in the way of

my cuts. Once I had all the scales in place, I shortened the

cables and resoldered the plugs back in place. The most difficult

part of this little task was getting the shrink tubing the right size

to fit inside the plugs and not shrink while I was soldering the

connections. This was one of those tasks where it would have been

helpful to have a couple more hands.

So after about a week and a half of working and waiting for the QCC-100

parts, the scales were installed and the DRO had all its digits

again. The 2 new scales seem to work just as well as the one I

have had on the X axis and having the 5/10,000 indicator actually flash

between each thousandth is nice. I have the DRO filtering set to

0 and there's not a hint of jitter. Quite a nice upgrade.

I am not an electrical engineer. I believe my description of the way the circuit works is accurate, although a bit incomplete. If you find errors in my descriptions or diagnostic steps, I'd appreciate hearing about it.