|

| HOME What's New

Workshop Stuff South Bend 405 Lathe Bench Grizzly G3103 Mill Bringing Home a

Sheldon 12" Shaper

|

Way Alignment

Tool

May 21, 2016

Back in 2010

when I was getting ready to scrape my import mill, I made a crude

approximation of the King Way alignment tool. It used flat stock

for the horizontal bar and only used a one vial 6" level that I

had made using some cast iron and a Starrett 199 - 0.0005" per 12"

resolution spirit vial. Around the same time, I also made a cross check level

using two of the Starrett vials, but there was no easy way to

attach it to the flat bar of the makeshift alignment tool. The

tool helped with scraping in the mill, but I realized that I

needed to make another one that was a little closer to the

original King Way design. I shelved the project for another day.

Six years later, that day has come. I have a scraping project

coming up where a proper dovetail way alignment tool would be a

big help.

Over the years,

I have read a lot about the King Way alignment tool and have

collected pictures of the King Way and some shop made copies. The

tool is ingenuously simple. It uses a horizontal bar to hold the

cross check level, two vertical bars to hold a ground sphere on

one side and a tube with a slot on the other, and an arm to mount

a dial test indicator (DTI). In use, the tube with the slot is

placed on the dovetail or V ways, the ball has a ground ring

placed beneath it and is positioned on the opposite ways. The

cross check level is then set to level in both planes and the DTI

is placed in contact with the way you want to measure for height

or divergence from parallel. By sliding the tool along the ways,

you get your readings.

|

|

|

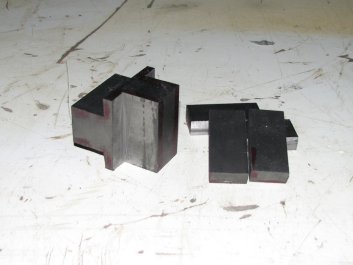

Squaring up some cast iron blocks. |

Cutting

out some sections to save milling time. |

I started the

project by squaring up some cast iron blocks on the shaper. I then

cut and milled the blocks so that holes could be bored at 90° to

each other. The holes were reamed to 0.501" diameter and then a

slot was milled with a slitting saw so that the 1/2" diameter

ground bars could be clamped in the holders.

|

|

|

Reaming the holes to 0.501". |

Progress

so far. |

The shape of

each holder was refined a bit and threads were tapped so that the

clamp could be tightened on the bar. If I had to do the job again,

I would change the design of the two bar mounts so that the

mounting point of the horizontal bar would be at the top of the

mount that supports the vertical bar. This would have allowed me

to make the level holder a bit shorter.

|

|

|

Refining the shape. |

A

little more progress |

When the holders

were finished, I gave them a couple coats of paint using rolled up

paper to keep the paint out of the reamed holes.

|

|

| Time

for some paint. |

Test

fitting the tool on the lathe. |

With the two

holders completed, I set the tool up on my lathe so I could

measure how wide the holder for the cross check level could be.

While I wanted to be able to set up the tool on the tailstock ways

of my small South Bend lathe, the closest I could get the upright

bars with the level between them was about 3.5". The distance

between the two inner ways of the SB are about 3.0" center to

center. This means that I will have to mount the level to the

outside of the uprights when working on the tailstock ways. I

could have narrowed the level holder clamp, but I was concerned

that the weight of the level would rotate on the horizontal bar.

The original King Way tool gets around this by slotting the

horizontal bar and using a thumb screw for the level holder that

locates in the slot. I am using two screws to clamp the holder to

the bar. So far, it seems to work well.

|

|

| I need

to measure the distance between the holders and how much

clearance I have for the cross check level. |

Rough

milling the holder that will attach the cross check level

to the horizontal bar. |

When I made the

cross check level, it was machined from a round of cast iron. It

is 6" x 7.5" x 1.25" thick and it is pretty heavy. I was worried

that if the T shaped leg of the level was centered on the

horizontal bar and I used a short tube when testing bed ways, the

whole tool would tip toward the leg on the long side of the level.

My solution was to make the level holder able to be reversed and

thus get the bar clamp closer to the balance point of the level.

This worked out very well and even with the short 5.5" slotted

tube, the alignment tool doesn't want to tip when I tried it on

the lathe.

The level used

on the King Way tool looks to weigh less than mine. From what I

understand, it also uses 0.0003" per 12" vials. The bar clamp

appears to be cast into the level base rather than being an add-on

piece like my copy.

|

|

| Test

fitting the holder to the level. The level overhangs the

holder by a lot on the right side. |

I made

the holder so it could be reversed. This moves the balance

point a bit to the right. |

Once I had the

level holder machined and I was able to make sure that it was

square with the level, I drilled and reamed a 0.501" hole for the

cross bar. I then machined a slit so that the holder could be

clamped to the bar. Last, I refined the shape of the holder and

added a couple pockets in the sides so that the vertical bars of

the tool could be moved closer together. The upright bars can be

adjusted to accommodate ways from about 3.5" to 15" apart with the

current horizontal bar while holding the level between the

uprights. For checking ways that are closer together than 3.5",

the level can be moved to sit outside the uprights.

When I built the

cross check level, I ended up making typical vial adjusters after

a couple of unsuccessful designs. I ended up with coarser threads

than are generally used for this purpose. My last design used 8-32

studs and cone shaped nuts that fit into reamed and slightly

beveled holes on the vial holder end caps. To raise one side of

the vial, you loosen the top nut, then raise the lower nut, then

lock the top nut back down. This was a little fiddly because the

8-32 threads lift and lower the vial more than the resolution of

the vials with barely a fraction of a turn. It took some of time

to get the level adjusted, but once it was adjusted, it seemed to

stay put pretty well. After more than a year of storage, the

bubbles still centered perfectly. Now that I was using the level

on the alignment tool, I needed to be able to re-level the vials

with each use of the tool. I also wanted the ability to adjust the

vials more finely. To do this, I decided on using a differential

screw adjuster on one side of the vial holder. I had a spare

brass end cap I had made when I built the brass vial holders. For

a proof of concept, I tapped this end cap for 1/4"-20 threads. For

the adjuster, I used a 1/4"-20 bolt with 8-32 internal threads

tapped in to fit on to the 8-32 studs. This allowed me to raise or

lower one end the vial holder by 0.01875" per revolution of the

bolt. Not a fine enough adjustment for the sensitivity of the

0.0005" per 12" resolution vials, but better than the 8-32 threads

alone. The test worked out very well. I found that I could adjust

the vial pretty easily.

To make the permanent adjusters, I ordered some 1/4"-28 threaded studs and a 1/4"-28 tap. The closer the thread count of the differential screws are to each other, the finer the adjustment. The 1/4"-28 and the internal 8-32 threads would give me 0.0045" height adjustment for every revolution of the adjuster. A tenth of a revolution on the adjuster would raise or lower the vial holder by about half a thousandth. Not a super-fine adjustment, but it should be sufficient. I turned and knurled some adjustment thumb screws from brass to top off the adjustment screws. To get both gross and fine adjustments, I turned an 8-32 adjuster for one side of the vial and use the differential screw on the other. One side for gross adjustment and the other side for fine adjustment. Though they're not shown in the picture below right, I ended up putting springs under each side of the vial holder end caps to help hold the vials to their adjustment. I have to say that the adjusters turned out to work as well as I had hoped they would. It is very easy to get the level into adjustment as long as I have the cross bar somewhat level.

I made up a new

slotted tube from the only appropriately sized stock I had on

hand, 1" schedule 40 steel pipe. I need to purchase some tube with

a 1/4" wall thickness to make the proper part, but decided that

making a slotted tube from the schedule 40 pipe would give me a

chance to play with the tool and get some practice using it. I

also need to find my shop made tool post grinder to grind the end

diameters of the next tube I make. I haven't come across it since

we moved into the new house and shop, but I still haven't unpacked

all of the boxes yet.

In the last two

pictures, the new slotted tube has been machined. The center

section of the slot in the tube has been relieved so that only the

1" sections at each end contact the ways. To get the mating

surfaces of the ends of the tubes square with the ways, I put a

coat of ink from a felt tipped marker on the four flats, then

rubbed the tube against both some V and dovetail ways. I used a

fine file on the area where the ink had been rubbed off until I

had four surfaces that contacted flush with the ways. The process

was very similar to scraping flat surfaces, only I used a file

instead of a scraper. Before I aligned the tube's slot, I tapped

four holes into the tube. Two for V ways and two for dovetail.

Because the pipe is so thin, I didn't get much thread engagement

for the 1/2"-13 threads I turned on the ground 1/2" O1 stock , but

it will have to do until I get the proper thick walled tube. The

extra hole for each position will allow me some choice in

positioning the slotted tube to see what works best.

With the tool

more or less complete, I set it up on my SB9 lathe to test it out.

Since the tailstock ways on the workshop lathe are only about 3"

apart, I needed to move the level to outside the uprights. Since

this puts the weight of the level to one side, I needed to

counter-weight the horizontal bar to keep the tool from tipping.

Not the best procedure, but it seems to work OK.

For my test of

the new tool, I will attempt to measure the wear of the saddle

ways on my lathe. It should be good practice for the upcoming

project. To make sure that I am getting true readings, I will

first check and correct for any twist in the lathe bed. The

tailstock ways are realatively unworn. The scraping that was done

at the factory to dust off the planer marks when the ways were

machined are still evident, so using the tailstock ways to check

for twist should be pretty accurate. In the past, I have attempted

to correct for any twist by turning collars on a long piece of

stock, then shim the lathe bed until I was able to turn the

collars to pretty close to the same diameter. I currently have a

0.002" shim on the operator's side of the lathe bed foot at the

tailstock end. However, as some sage person once said, "Machine

tools are made of rubber." Add the fact that this light lathe is

mounted to a butcher block bench and there is no doubt that the

twist of the bed could change with the seasons. I am looking

forward to seeing how close I can get the lathe to being free of

twist and then checking the lathe for wear.

Using the setup

shown in the last two pictures, using no DTI and just reading the

level bubbles, I checked the tailstock ways for twist. The

readings I got made me scratch my head. With both vial bubbles

centered at the headstock end, I moved the tool to the right about

six inches. The bubble measuring the X axis, the direction that

the top slide moves, showed three increments high on the flat way

side. I slid it toward the tailstock another six inches. It was

now showing two increments high. At the third six inch stop, or

18" from the headstock, the bubble was centered again. The vial

for the Z axis, left to right along the ways, showed the bubble

pretty close to centered at each stop. I set up the DTI to measure

the outer angled flat of the front V way and repeated the test.

The V way showed less than 0.0003" deviation over the 18". It

showed a little wear about 6" from the spindle snout and 0 in

front of the snout and after about 12" from the snout.

Apparently I

have a hump in the ways closest to the operator. Three divisions

of the Starrett 199 vials would be 0.0015" per 12". That seemed

like a lot. I quit for the night and decided to give it some more

thought. The next day, I repeated the test with the same results

and then it dawned on me that I was using vials calibrated to

measure 12" and I was actually measuring the rate of slope for

ways 3" apart. Duh. So the hump is there, but it's not 0.0015",

it's closer to 0.00035". To confirm my thoughts, I re-leveled my

surface plate using my frame level (0.0002" per 10") and used a

0.100" and a 0.10025" gauge block under my best wide parallel with

the frame level above it. The results from placing the gauge

blocks 12" apart and 3" apart and measuring their respective

slopes confirmed my thoughts. Sometimes I need to spend the extra

time to confirm what I think I know.

I will have to

remember that the distance between the slotted tube and the sphere

determines the amount of rise or fall that is depicted by each

increment on the spirit vial. As for the South Bend, while I would

prefer no hump in the ways, 3 1/2 ten-thousandths is a lot better

than a thousandth and a half. I doubt that I will do anything to

try and correct this. I have learned to produce pretty accurate

work on this lathe in spite any deficiencies it may have.

Knowing where it is inaccurate will help me to produce better

work.

I have a couple

old lathe beds that I will spend some time mapping out. I need

some practice time with this tool before I start using it to help

me scrape ways that are true.

© Fager May 21, 2016