While I

pondered how to keep the bearings clean, I was also looking for proper

replacement bearings and maybe a new or used spindle - if one happened

to show itself. I put up some ads on a couple of bulletin boards

I frequent and sent email off to a dozen or so spindle

rebuilders. I didn't have much luck finding a replacement

spindle. The rebuilders wanted to rebuild mine and the prices

were a bit more than I was prepared to spend at this point.

|

|

Angular

Contact Bearing - back to back configuration

|

Spindle

drawing - measurements and layout

|

Before I could look for

bearings, I needed to pull the spindle apart and find out the quantity

and size(s) I needed. During my reading, I did find out that I

needed to pay close attention to how the bearings came out so I would

know how to reinstall them. Angular contact bearings can be

arranged in a few different configurations depending on what the

manufacturer had in mind. The configuration is first dependent on

how many bearings are needed to support the spindle shaft and then

dependent on how much and in which direction the forces will be applied

to the spindle. When I finally got the spindle apart, I found a

total of 4 Barden 107 matched angular contact bearings (two on each

end) in back to back configuration. Back to back in Barden's

symbols is shown as / \. Each slash indicates the axis of the

balls when viewed from the side and the ball at the top of the

bearing. Each pair of bearings have the printed sides touching as

shown in the image above. Other possible configurations are face

to face ( \ / ) and face to back ( / / ). On the back end

of the

spindle, both the face to face and back to back configurations would

have the bearings in the same configuration as on the front of the

spindle. For a spindle with face to back on the front, the rear would

be the opposite, or back to face. This configuration preloads

the bearings as two front against the two rear( // ----- \\ ), rather

than the more

common preload of 1 against 1 in the front and 1 against 1 in the

rear ( / \ ----- / \ ). From my limited experience in mills,

lathes and grinders, I

have seen back to back used most often.

|

|

Cleaned and bagged - just like a

small clean room

|

Red/blue boxes show high run out

marks on old/new bearing. Set marks 180° from spindle high marks

|

I had been

watching Ebay, among other sites, for Barden 107 bearings. I had

found a cross-reference

for bearings that showed that Barden's 107 number matched a few other

manufacturers 7007 numbers. I set up automatic searches for those

numbers also. The letters and numbers after the size designators

include nomenclature for a matched pair of bearings, whether they were

duplexed and whether the duplexing was face to face, back to back, or

whatever. The letters and numbers also depict whether or not the

bearings are marked for radial run out and how much maximum run

out. These numbers are not etched on the Barden bearing

shell. They are found only on the sticker that comes on or in the

box. On the second day I checked for Barden 107* on Ebay, I found

my bearings. The seller only had one pair listed, but when I

wrote him with a ton of questions, he graciously answered my questions

and said he had another pair as well. I ended up with 2 pair of

107HDL with codes for duplex back to back, light preload, I.R.

radial run out 0.00005 max. There's a good page with the Barden

nomenclature here.

The nicest part of the purchase is that 2 pair cost me less than 1/2

pair would have cost retail. Sometimes I get lucky.

While I waited for the bearings to arrive, I set out to find some

bearing grease. I had learned that one doesn't use unfiltered

grease in a bearing with these close tolerances. Just like the

bearings, the grease is special. The recommended grease for my

application was Kluber Isoflex NBU-15. It was a bit of a search

to find it. McMaster has something close, but not quite as good

for my application and the smallest size was a lot more than I

needed. Barden recommends only 2 cc of grease per each 107

bearing and too much grease can cause the bearings to overheat. I

finally found 30cc syringes of the Kluber from Precision Spindle.

I gave them a call on a Monday and had the grease on Wednesday.

Fast service.

With all of the individual parts cleaned and bagged, I pulled the

bearings out of their packaging while my freshly gloved hands, a couple

of new zip-close bags, some lint-free wipes and the grease syringe were

all inside a large clear plastic bag. This was my clean

room. With the clear bag surrounding everything, I was able to

inject the 2 ccs of Kluber grease in each of the bearings and work it

around, then put each pair of bearings in the small zip bags. The

only dust that the bearings may have seen would have to have come in

when I carefully opened it to add the bags, grease, etc. It's

still not as good as having a clean room, but it was a heck of a lot

cheaper.

|

|

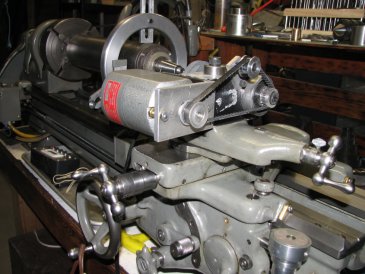

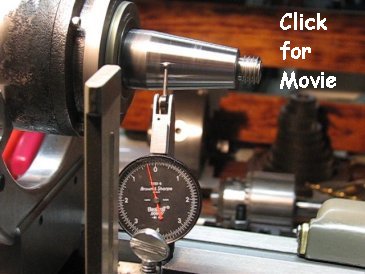

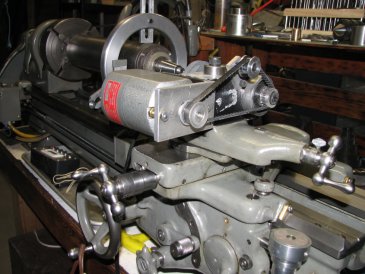

Making sure that the spindle

wasn't bent

|

Shop made tool post grinder (TPG)

|

|

|

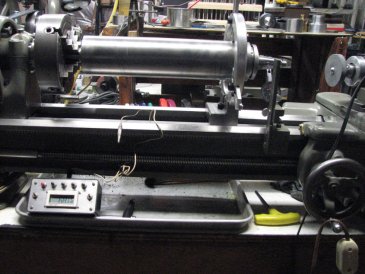

Checking for concentricity of the

taper

|

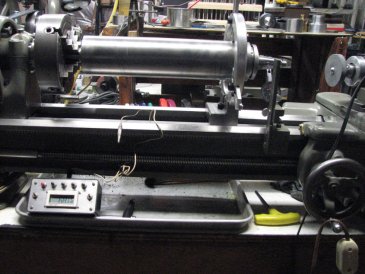

Checking the temps as run-in was

done on lathe

|

Once the

bearings were greased, I removed my wrapped spindle from the freezer

and tried to slide the warmed front bearings over the

journal. They were a little too tight for this to work, but

I was ready for this possibility. I moved the bag, with spindle

and one pair of bearings inside, to the cleaned and waiting hydraulic

press. Everything was already set up for this press job.

With the bag still surrounding the spindle and bearings, I pressed the

front bearings home with a press-tool on the inner race. I didn't

even tear the bag. Still working in the bag, I moved in the

clean spindle housing from another bag. Back to the press.

This time the press-tool pressed on the outer race to seat the bearing

and spindle shaft into the housing. Next, I added the front

spacers and end cap and cinched them down finger tight. The last

job on the press was the one I was most concerned about. I needed

to press the pair of rear bearings on to the spindle shaft and into the

housing at the same time. Fortunately I had already made sure

that the inner press tool was able to nest inside of the outer press

tool, and so put equal pressure on both races. This required

using a shim on the outer race for the first bearing, then removing it

for the second bearing. These bearings are NOT an interference

fit, just a very close sliding fit, so there was very little actual

pressure being used. Once the rear bearings were close to their

intended location, I added the cleaned spacer, nut and end cap.

With the inside of the housing now closed off from the outside and

little possibility of dust entering near the bearings, I was able to

tighten down the end caps. Tightening the end caps sets the

preload. There's no measuring torque or any computing done at

this stage. As long as the new bearings measured the same as the

old ones in thickness and they had the same preload rating (both old

and new were "15° - light preload"), then the preload setting

machined into the bearings would automatically be correct. I had

measured everything before I began the assembly and it all looked

right, but it was reassuring that when the nuts and end caps were

tightened, there was no end play in the shaft and just a small amount

of drag when the shaft was turned in the housing.

I chucked up the spindle in a 4-jaw on the lathe and used a steady rest

with the fingers reversed to hold the housing. Starting in back

gear at the lowest RPM, I ran the spindle while checking the

temperature of the housing above each pair of bearings. When I

finally got up to around 1000 RPM and let it run, the front bearings

were reading about 92° and the rear about 90° at the 15 minute

mark and had dropped to about 80° by the end of an hour. I

had looked for specs for bearing temperatures, but didn't find much

more than "The bearings shouldn't run hot." Since the spindle

normally spins at 3000+ RPM, they might have run hot if I would have

spun it up to high speed in the beginning, but by running it in slowly,

I was able to avoid that issue.

I let the spindle run for another hour. By this time, the housing

temperature was just a few degrees over the ambient room temperature of

74° at 1000 RPM. The next step was to grind the spindle

taper. I had built a quick and dirty tool post grinder as an

early project to grind an inside taper on a end mill grinding

jig. I didn't use angular contact bearings, but did preload the

bearings a bit to lessen the end play. I doubt that these

bearings will last too long, as they were not meant for this type of

service, but it was better than using a Dremel as a TPG.

I dressed a 3" wheel, set the compound slide to a little over 7°

and made a very light grind with the lathe turning the spindle at about

350 RPM. I checked the angle with some Prussian blue and an

almost new Sopko adapter. It took a couple trys to get the angle

correct, but once I had the angle right, I ground about 3 thousandths

off of the taper. The diameter of the spindle shaft is 1.0625"

just inboard of the taper, so the 200 series adapter, with its 1.000"

maximum inside diameter doesn't seat all the way down on the

taper. This is nice as I could regrind the taper many times

without running out of real estate.

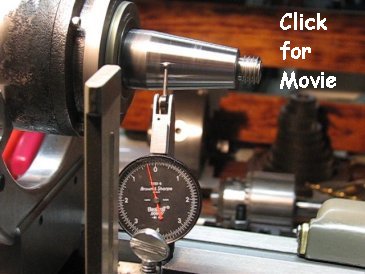

So how did it turn out? I'm so amazed at the job this tool post

grinder did, that I had to shoot a short clip of the outcome.

There is just a hint of a waver from the needle on an indicator that is

graduated in 50-millionths of an inch (half-tenth). Not too

shabby.

|

A

little out of focus at start, but almost zero run-out

|

The finish

on the taper could have been nicer with a better grinder or maybe with

a better choice of wheel, but it is so much better than the 0.0012" run

out I started with, that I'm quite happy with the results. I got

so excited with the results, that I went ahead and reinstalled the

spindle in the grinder that evening. I paid for this the next

day, as I didn't get to bed until almost midnight on a Sunday night

with a very early alarm (4:30 AM) on Monday morning. I told

myself that I wouldn't have been able to fall asleep anyway, due to thinking about it.

For the last week or so, I have been doing lots of grinding. On

most things, the finish I'm able to get is very nice. On others,

I find that I have lots to learn. However, any finish problems

I've had can't be blamed on the spindle taper not being true - and

that's a good thing! I reground the table, the chuck, some long

thin stock for practice and I am now working on some fixtures to assist

me in grinding some templates so I can do a good job of scraping in a

fairly "new to me" South Bend model A saddle and cross-slide I added to

convert my 405 "C-type" lathe to a "B-type" lathe. They were not

very worn and the saddle checked favorably against my very slightly

worn South Bend 405 bed ways, but I have been wanting to "do the job

right" and scrape the saddle ways to a perfect fit. Since I

needed to remove the saddle in order to clean the grinding dust from

the lathe anyway, now would be a great time to scrape it in. Yes,

I threw a towel over the lathe while grinding, but I know that the

grinding dust still gets through. The dust settles on surfaces

all over the basement and gets kicked up for a while after a grinding

job. This is one of the reasons why the surface grinder lives in

the garage - away from the rest of the machine tools. Well, that

and because it was too much work to move it to the basement.... but

that's another story.

Here's a parting shot of a pair of

parallels that I ground after the spindle repair. Not too bad

of a finish for a novice..