|

Sheldon 12"

Shaper - pg. 6

October 14, 2015 - November 9, 2015

When I finished

the last installment, I had taken a test cut. The test cut was

pretty successful considering that I hadn't used a very good

method of holding the cast iron test block to the table. I had

seemingly solved the problem with the tool head creeping downward

during cuts. The tool head lock was also working as it should.

However, I had run into another issue. Two steps forward and one

step back. The stroke made by the ram, which can be set from 0" to

13.5" was increasing in size as the shaper ran. I had set the

stroke to 7" and by the time the table moved 4" laterally to

finish the cut across the width of my test block, the ram stroke

had increased to 10". Obviously, something wasn't right.

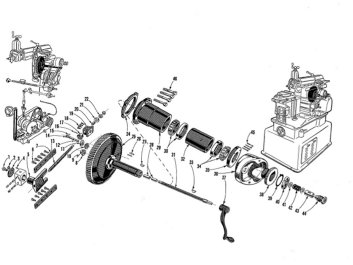

Looking at the stroke adjusting rod in the parts breakdown (below

left), I noted that part #44 was labeled as a tension nut (expand

the image for the names of the parts). Since it had a spring

behind it, I was hoping that this nut would be able to make the

adjusting shaft a bit harder to turn and solve my problem. To get

at this nut, I pulled off the two arms (#5 and #33 in the second

picture). I also removed the two screws that appeared to hold the

cover in place. At that point, I didn't realize that the parts

image I was looking at (below left) didn't have all of the parts

shown. The screws are part #21 on the second image. With

everything I could see that appeared to hold the cover in place,

it wouldn't budge. I messed with the cover for about an hour and

called it quits for the night.

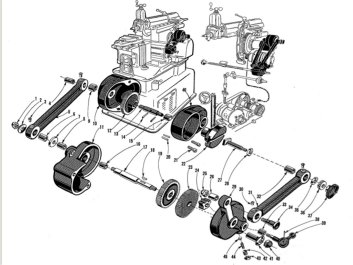

The next day, I looked through the parts drawings again and found

the second image. This time I saw there were also two taper pins

(#20). One next to each of the two screws. I measured both ends of

the one taper pin I could easily get to and found that the small

end was on the back side of the housing. There was no way I could

get a pin drift and hammer in that small space to knock out the

pins. What to do? I cobbled together a C clamp with a pin on one

end and a socket on the other to try and press the pin out, but

knew that the effort would be futile. It was. These pins were

stuck in place.

|

|

| Page 6

from the Sheldon Shaper parts manual. Click to enlarge and show the part names. |

Page 8

from the manual. Click to enlarge and show the part names. |

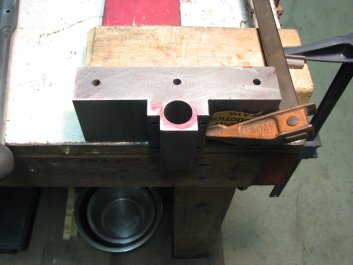

I had noticed

that there were two studs with locking nuts on the top of the

cylindrical housing that attached to the rear housing of the cover

I needed to remove. These are not shown on either of the parts

drawings. When I was cleaning the shaper and trying to understand

the purpose every nut and bolt, I had assumed that these were for

some sort of adjustment, but what that adjustment could be I

didn't know. Each of the studs had a socket for a 1/4" Allen key

and the lock bolts took a 3/4" wrench. You can see one of the

studs with its lock nut on the 6th image on top of the

housing on the right. With nothing left to try, I decided to mark

the position of each of the studs so I could return them to their

current position and see what happened if I loosened them up. This

attempt solved the problem of removing the cover. With both studs

backed off by 1/2 turn, the whole housing assembly was free to be

pulled off of the machine. The two studs press on the inner

cylindrical housing that attaches to the shaper body and hold this

housing in place. To replace it, it appears that you just push it

back on and position it so that the two arms fit and tighten the

studs and lock nuts.

Once the housing

assembly is removed, I found that I didn't need to remove the

cover that I had been fighting to get off unless I wanted to take

a look at the gear that drives the table indexing for its side to

side travel. This is another case where experimenting can lead you

to a discovery. Even though it wasn't necessary for the current

repair, I decided to go ahead and drive the old taper pins out and

remove the front cover. As long as I had the assembly out, I might

as well clean the rust off of it and check the gears for wear.

After all, this is a 60+ year old machine and I am assuming that

this is the first time it has been disassembled this far. The

taper pins came out with a couple whacks with a hammer on a pin

drift. The pins were a little rusty and the small ends had been

mushroomed a bit by my knocking them out. Contrary to my usual

situation of not having the correct pins in stock, I happened to

have a good supply of the correct taper pin - #2 pin, 1" length. I

have more of these than I could ever use. If you need a couple,

send me an email and I'll drop a couple in the mail for you.

With the

adjuster nut exposed, it was time to see if I could increase the

tension on the adjusting shaft so that the shaft wouldn't turn on

its own. The adjuster nut takes a 1 1/8" wrench and I had assumed

that I would need to tighten the nut a small amount to add some

tension to the shaft, but I was wrong. To be on the safe side, I

again marked the position of the nut on the shaft so I could

return it to the position I found it in and then tried tightening

the nut clockwise by a quarter turn. Tightening the nut took

tension off the shaft. OK, no problem, let's try turning the nut

counter-clockwise. I turned the nut back a quarter turn, then an

additional quarter turn. The shaft appeared to get a little harder

to turn. I went another quarter turn and the shaft was now locked

up from rotating. I backed off (turned clockwise) about a 1/16th

turn and tried cranking the adjuster rod again. It seemed to have

more tension but wasn't too hard to turn. I will try it here. If

the truth be known, I have no clue whether my adjustment will

solve the problem. However, it seems like it should. I guess I

will know soon enough.

Since there is a

fair amount of dirt and rust on all of the parts in this assembly,

I decided to clean things up a bit before I reassembled and tried

another test cut. While I would like to reassemble the machine and

take a test cut right now, I know myself too well. If I don't take

the time to clean up the rust, it will not get done until I decide

to strip the whole machine for painting. Since that's not on my

agenda right now, I might as well do what I can to get rid of the

rust.

It turned out to

be well worth my time to strip down the housings to clean the

parts and give the painted parts a better coat of paint. I ended

up finding a couple parts that might have been lost if I wasn't

paying close attention. The two studs with lock nuts that secure

the housing assembly to the cylinder on the side of the shaper do

not bear directly on the cylinder shown above right. There are two

wafer thin bronze shoes that sit at the end of each stud that fit

between the studs and the cylinder they bear on. One fell out

while I was cleaning up the rear cover housing. As soon as I saw

it, I knew what it was and scolded myself for not checking the

bore of the housing more carefully. I was lucky it didn't end up

on the floor to be vacuumed up later in the day. The other disk

shaped shoe was still on the end of the second stud. I removed the

shoe and both studs and continued cleaning the housings so I could

give them a coat of paint. I got one coat of paint brushed on in

the late afternoon and another coat later that night. Hopefully I

will be able to reassemble everything tomorrow and test to see if

I have fixed the issue with the stroke increasing on its own.

To get the

eccentric off (lower left photo - the part with the divisions),

you need to remove another taper pin. This one is driven out from

the gear. The size of this one is a #1 - 1 1/4" in length. This

pin came out easily and can be reused, but I have some of these in

stock also. I may not have all sizes of nuts and bolts on hand,

but I have an excess of taper pins. All of them received from a

guy who was down-sizing his workshop. With the taper pin out, the

gear pulls off from the rear and the eccentric pulls out from the

front with the attached shaft. I cleaned and buffed all the shiny

bits and added a coat of paste wax to help to keep them from

rusting. I wax pretty much everything that is bare metal after

finding that just wiping parts with way oil every few months

wasn't enough to stop the surface rust I get in this shop. I have

only been using the carnuba paste wax for a couple months, but it

seems to protect the bare metal very well. I put it on thick and

don't buff all of it off. A quick wipe with a rag or shop towel on

parts like squares of parallels gets them ready for use. So far, I

like this a lot better than way oil or the spray on anti-rust

coatings, but I have yet to go through the worst part of the year

for rust. Spring and early summer seem to be the rust seasons in

my shop.

Another

interesting thing I found is that the two bronze bushings that

support the eccentric's shaft have no provision to be oiled. Page 8 of the parts manual

says that they (#9 & #15) are bushings. Other bushings on the

same page are listed as Oilite bearings. From their appearance, I

believe these are the Oilite type also. Oilite bushings are made

from sintered bronze and are oil impregnated, but I would prefer

to be able to oil them when I use the shaper. Since there is no

way to oil them without disassembling the housing, I will recharge

them with oil. To recharge them, you soak them in mineral oil that

is heated to 80° to 100°F and let the bushing cool to room

temperature. I have also read that they can be recharged by

placing the bushings in oil under a vacuum. I will soak them in

heated oil and let it go at that. The shaft that turns the

eccentric spins slowly and after 60 years, there is very little

play between the bushings and shaft. The gears are also in great

condition. There is virtually no wear, just a nice even polish to

the face of the teeth.

After heating up

some ISO Grade 32 turbine oil and soaking the bushings in it for a

couple hours, I cleaned up the mess and reassembled the housing. I

used some grease to hold the bronze shoes in place and reinstalled

the housing. The whole process went pretty quickly and I was soon

ready to reattach the two arms. The rear arm secures the housing

to the back of the table advance mechanism which is connected to

the cross rail. The front arm connects the eccentric to the front

of the advance mechanism and is responsible for moving the

ratcheting cogs that move the table either left or right.

When I had

initially checked the tightness of the studs on the housing, I had

found that the two studs were not all the way tightened down. Once

I found that loosening them allowed me to remove the housing, I

didn't give their tightness much more thought. When I reinstalled

the housing, I cranked the studs until they fully seated the shoes

against the cylinder they pressed against. I reinstalled the two

arms and figured that I was ready to take a test cut. I mounted

the test block on the table and started to raise the table into

position. After one or two cranks, the table wouldn't elevate any

more. After a couple moments thought, I realized that the rear arm

(below right) tied the housing to the cross rail. The cross rail

is what moves when you raise and lower the table. Instantly, the

signs of wear on both the shoes made sense. The housing was

supposed to rotate as the cross rail was raised and lowered. If

the housing couldn't rotate, it bound up the cross rail. It was

one of those "Duh" moments.

I backed off

both the studs by enough that the housing could rotate and I could

now raise and lower the table. I was set. Or so I thought. I

started my test cut and by half way through the 4" wide cut, the

stroke was advancing on its own again. I removed the arms and

pulled off the housing once again. I checked the tension on the

stroke adjusting shaft and it turned a little easier than I

thought that I had set the tension to. I would try again. This

time, I turned the adjusting screw counter-clockwise until the

stroke adjusting shaft had a good deal more tension while turning

with the crank. If I get it right this time, I will put a constant

reading torque wrench in place of the crank to check the amount of

resistance when I turn the shaft. Hopefully having a reading in

inch or foot pounds will help in case I need to go through this

again.

I reassembled

all of the pieces I had removed and tried cutting my test block. I

had a better outcome this time. I was able to cut the whole 4"

wide surface without the stroke straying from where I had set it.

At this point it is a little early to say that I have fixed the

issue. I will try some more cuts tomorrow. If it holds the

adjustment without the stroke increasing, I will then be a bit

more confident in saying that it appears to be fixed.

The next

evening, I spent a few hours running the shaper. The issue with

the stroke increasing by itself appears to be fixed.

I planed a few

pieces of different sizes and materials, all of which were mounted

directly to the table with studs and wedges. I had given up on

using the two piece vise and was now using blocks and wedges.

These have their own problems, but I will get to that in a

moment. Each piece, after being planed on two opposing

sides, was then transferred to the surface plate and checked for

being parallel with the plate. My worst case readings were about

0.001" per 6" out of parallel in the X axis. The Y axis

measurements were always about half the error of the X axis.

Not bad, and certainly better than before I started scraping, but

not as good as I thought it should have been. I have read that

being able to plane to around a thousandth is thought to be pretty

good for this size of machine. Remarks like "the shaper isn't a

surface grinder" come to mind, but I am sure that with some time

to refine my setups, my planing errors will come down a little.

|

|

| Checking

for parallel between the vise rails and the bottom scraped

surface. |

The

surfaces came out pretty close to dead on. I am very

pleased with the results. |

Since the stroke

was now staying put, it was time to plane the rails of the shaper

vise body. With the bolt holes in the vise body to allow me to

hold it to the table securely, I thought that this would be the

first good test of how accurate the shaper was. The bottom of the

vise body was scraped flat and I had rechecked the table with a

straight edge to make sure that there were no burrs. Due to the

vise jaw and the need to under cut the bottom of the vise jaw a

small amount, I decided to use a tool bit mounted directly to the

clapper. Not the best setup due to a lot of extension on the tool

bit, but it ended up working very well. The vise rails came out

almost dead flat and parallel with the bottom of the body. The

finish came out nice enough that I don't feel the need to scrape

it. I think that my test blocks were coming out a little less true

than the vise body did due to the poor method of holding the test

blocks to the table. With the test block only being held by the

side forces from wedging against some hold down clamps, I wasn't

getting as much downward force as with the vise body. Even though

I had tapped the block with a mallet to seat it, it's hard to come

close to the force exerted by bolting something to the table.

|

|

| The

vise has been mounted to the swivel base and I am now

checking parallel for the whole assembly. |

Again,

the results are very good. The time spend scraping the

vise surfaces has paid off. |

I mounted the vise body on the swivel base and measured again on the surface plate. It appears that I did a pretty good job on my scraping. The rails are withing a couple tenths of being parallel everywhere I put the DTI. I am happy with the outcome. The next step was to test and grind the vise jaws or make some new ones. I will probably end up doing both. The vise jaw faces were pretty scarred up and were both a little bowed. The worst one allowed me to slip a 0.010" feeler gauge under the center. I took the jaw pieces to the hydraulic press and set up a couple blocks to try and get the bow pressed flat. This is tricky work, but after an hour or so, I had both jaws flat enough to put them on the magnetic chuck of the grinder. I ground 0.007" off of one side of both jaws, then flipped them over and ground another 0.008" off the other side. I printed them on the marking surface plate and they looked good.

|

|

| The jaw

faces are not in the best of shape. That's a 0.010" feeler

under the jaw on the right. |

The jaw

faces are attached for a test fit. Some testing revealed

that I still have some work to do. |

I mounted the

jaw faces on the chuck. I then stacked two, half inch thick, one

inch wide, by six inches long parallels on the rails and tightened

the vise jaws snug. The bottom parallel held tight, but the top

one could be moved. There wasn't a lot of slop, but there was

enough that the top parallel wasn't trapped by the jaws. Hmm, this

isn't good. The jaw faces don't seem to be parallel.

I had already

measured and machined a step into the two rub plates on the

underside of the rails that hold the moveable jaw tight against

the vise rails. I did this to adjust for having planed the rails.

Planing the vise rails had introduced more of a gap between the

rub plates and bottom of the vise rails. I had relieved the

portion of the rub strip that mounted to the moveable jaw so that

I had less than a thousandth clearance between the rub strips and

the bottom of the rails. The moveable jaw was as tight to the

rails as I could get it without making the jaw hard to move. It

was now time to do some measuring to see where the problem lies. I

had hoped that the jaws would have been perpendicular with the

rails, but knew that this probably wouldn't be the case. While

I've rebuilt a Kurt clone import mill vise with good success, this

vise wasn't quite the same. Not to shift the topic, but Kurt has

some good instructions for rebuilding their D series vises here.

The mill vises like the Kurt D series have a removable fixed jaw

aligned with a key. The Sheldon vise has the fixed jaw cast along

with the base. From what I have read, for the best holding

ability, the fixed jaw should tilt a bit inward rather than being

machined or ground at exactly 90° to the rails. This is done so

that when the vise is tightened, the fixed jaw flexes into a state

of being very close to 90° rather than obtuse and past 90° by some

small increment.

|

|

| Scraping

the fixed jaw so that the top of the jaw is angled toward

the rear jaw by a couple tenths. |

The

moveable jaw's first print after knocking down a few burrs

with a coarse stone. |

Since I need cut

the stationary jaw to be a bit less than perpendicular, I thought

that the following operations could do what I needed: from least

to most accurate. Plane it on the shaper, if I shimmed the vise

base on the table to the correct angle. I wouldn't want to try and

set the tool head to cut a fraction of a degree. Using a cup wheel

on the grinder would also work, again by shimming the vise to

achieve the very slight angle I needed. Last, I could scrape the

fixed jaw. This would be a little more time consuming than

grinding, but since this is not a sliding surface, the points

count doesn't need to be very high. I chose scraping. Since

scraping takes metal off more slowly, I stood a better chance of

getting the angle where I wanted it. I clamped the vise body to an

8" angle block and clamped the block to the bench. I checked my

progress with a precision square backed by a bright light. When

the jaw was flat and I could just see a hint of light at the

bottom of the fixed jaw, I stopped scraping. It took less than an

hour to complete.

I reassembled

the vise with the hard vise faces and again tested the holding

ability. It was better, but not quite there yet. Time to check the

moveable jaw. Once the jaw was on the bench. I did what I could to

knock down the high points with a rather coarse grit stone, then

cleaned it, and put it on the marking plate. Aside from a ring

around the large hole where the screw resides there were only a

couple of burrs touching the plate. A couple cycles later, I got

to see something interesting. In the picture below left, you can

see that there is a hollow area across the top center of the

moveable jaw. Since the jaw face still showed the machining marks

from a large face mill, at one point in time it was fairly flat.

Now, not so much. I am always interested in trying to figure out

how surfaces get out of alignment. If I had to wager on this one,

I would put my money on compression/deformation of the top center

of the jaw from years by having smaller objects held in the center

of the vise and then cranking the jaws very tight. When I first

checked the vise, there was a lot of slop between the moveable jaw

and the rails. This meant that the top of the jaw was tilting away

from the fixed jaw when tightened. I'd guess that some

operator kept tightening the jaws to try to overcome the fact that

the work wasn't being held securely. The top center of the

moveable jaw is dished by about a thousandth. Time to do some more

scraping.

A couple sets of

step scraping passes and some finish scraping to even out the

points count a bit and I was ready to check the holding ability of

the jaws again.

|

|

| The top

center of the jaw is a bit hollow. I have more rough

scraping to do. |

After

another round of step scraping and some work to get a more

even bearing, I was done. |

This is the

first time that I have tried stacking parallels to check if the

vise jaws were true with each other. I don't know if I read about

this procedure somewhere or I came up with it on my own, but it

seems to work very well as a test. Out of curiosity, I checked my

milling vises using the same method. All of them passed the test

with only a slight snugging of the screw.

I reassembled

the shaper vise and tried the test without the jaw facings. The

parallels were both held tight with only the slightest pressure

from the screw. I then cranked the screw tight and there was no

change. Both parallels were still trapped tightly by the jaws. I

placed the top parallel at the very top of the jaws and repeated

the test. Same results and still good. I reattached both ground

jaw faces and tested again. I had figured that I would get the

same results, since I had checked the jaw faces with a micrometer

and on the surface plate and found that the grinding had brought

them to within a half tenth of being parallel. However, it was

still a nice confirmation that with the faces installed, that

testing with the parallels passed with flying colors. Cool. I had

succeeded in aligning the jaws. The next step was to get the tops

of the jaws parallel with the vise base.

|

|

| I

tested the jaw alignment with the top and bottom parallels

separated by a quarter inch. |

After

some time on the grinder and about 50 thou. removed, the

tops are parallel within 0.0002". |

The tops of the

jaws had a fair amount of battle scars. For about 60 years of age,

they looked about like you would figure. Not horrible, but the jaw

tops showed signs that, at least a few of the operators weren't

paying attention during its life. Initially, I was going to true

the tops of the jaws with the shaper and finish with grinding, but

my surface grinder hasn't seen a lot of use in the past few years

and it could do with some exercise. I had done a rough measurement

and knew I needed to remove at least 0.035" to get the tops of the

jaws lined up and this measurement didn't include the battle

scars. I ended up grinding off 50 thousandths and still had a

couple divots left. I ground pretty aggressively and was grinding

dry, so I introduced a bit of heat in the vise and that wasn't

good for accuracy. I decided to stop for the night and do a quick

measurement of the jaw tops on the surface plate, then grind the

remainder the next day. Even with a slightly warm vise, I measured

less than 0.0002" discrepancy over the seven inches of the jaw

tops. I hope to improve on that tomorrow.

With my grinder

coolant pump waiting on a roto-flex seal and the make-shift pump

not having enough head pressure to give a decent flow, I again had

to grind dry. I ground another seven thousandths off and had

finally removed all of the divots. I didn't feel any appreciable

heat in the jaws, but let them sit for a while as I re-faced the

stone for the final passes. I took a couple five tenth passes, a

few two tenth passes and then sparked out. With coolant, it only

takes a couple passes until there are no sparks coming from the

wheel as it traverses the work. Grinding dry seemed to take quite

a few more passes. When the grinder wheel finally stopped making

sparks, I was done. I have to say that changing the belt on the

grinder made a big difference. I am now seeing none of the

patterns on the ground surface that I saw with the old belt. I was

quite pleased with the surface finish. The finish of the ground

cast iron looks a little darker than the steel jaw faces, but both

the CI and the steel look very smooth and uniform.

I moved the vise

to the surface plate and was happy to see that I had improved the

surface. I was now reading less than a tenth difference in height

on the seven inch width of the jaws. It's about a half tenth

concave in the center. I was quite pleased that I could open and

close the vise jaws and measure no lip when I passed the stylus

over the point where the jaws met. If I cranked down hard on the

handle, the rear jaw lifts a few tenths, but that is to be

expected with the design of this vise. Overall, I think I did a

pretty good job. I will be interested to see the outcome when

trying to true up my test block.

As seems to be

typical for me, on the afternoon I finished grinding the vise, the

new roto-flex seal arrived. Hopefully I will again have a working

coolant pump on the grinder soon.

I touched up a

couple spots on the vise where I had damaged the paint and the

next evening, I mounted my cast iron test block in the vise. I

added some thin squares of paper under each corner of the block

and tightened the jaw. The end of the block nearest the moveable

jaw lifted a very small amount. Just enough that I could move one

of the papers a fraction before it became trapped again. I used a

mallet to tap down the block and snugged the jaw a little tighter.

All four papers were now trapped, but as I would find out, not

trapped well enough. I set the ram travel and position and turned

the shaper over by hand using the Reeves drive pulley. I happened

to turn the pulley the opposite direction and the ram didn't move

until I had turned the pulley about a half turn. Strange. I hadn't

noticed this before. I checked to see that the secondary shaft was

turning without the lag and it was. I surmised that the only thing

left to check was the shaft that runs the planetary gears that act

as the back gear. I pulled off the cover and found the problem.

When the lever is shifted into direct drive, there is a pin that

is forced into a hole in the shifter collar. There are two holes

on the shifter collar with a semi-circular relieved area between

them. Apparently when I had shifted into direct drive, I had only

seated the pin into the relieved area and not into one of the two

holes. This allowed the pin to move a half a revolution without

driving the collar. I will need to pay attention and make sure

that the pin is fully seated and the shift lever is turned all of

the way to its stop.

I set up to take

a 0.005" cut and got to enjoy watching the shaper peel of tiny

curls of cast iron. With the block resurfaced, I pulled it out of

the vise and measured it on the surface plate. The bottom of the

block had been surface ground, so I knew that it was pretty flat.

The questions was - how parallel was the top surface to the

bottom. The answer was that in the X plane, it was as good as I

was hoping for. There was more wavering of the needle on the

half-tenth resolution DTI due to the surface finish than there was

error that I was able to read. In the Y plane, it wasn't as good.

The end that was chucked nearest the operator was low by 0.0007".

I took this to mean that the moveable jaw had lifted and had

raised the rear of my test block a bit.

Trying to get to

tenths of accuracy is a fiddly business. Not only does everything

need to be spotlessly clean, but with this vise, it means that the

amount of clamping force can't be too high. The vise is not

designed like a Kurt where the moveable jaw is pulled downward as

you crank tighter on the screw. In fact, it's closer to the

opposite. When the screw is cranked tighter, the moveable jaw

tilts by, at least, the amount of clearance between the jaw bottom

sliding surface and the tops of the vise rails. With this in mind,

I decided to try the next cut with just enough force on the jaws

to hold my test block securely. This was the trick that made the

difference. After the next cut, I was still at around a tenth or

two in the X plane, but I had improved the Y plane to two tenths.

I spent the rest of the evening cutting the four faces of the test

block a couple thousandths at a time and checking the results on

the surface plate. My measurements over a dozen cuts went from a

tenth at the best to a worst case of a half thousandth over the

4.5" X 6.5" test block.

|

|

| This is

my attempt to measure flex in the over-hanging section of

the vise body. |

Instead

of flex, I am probably reading the machine rocking and

need to bolt the shaper to the floor. |

Early in the

process of working on this shaper, I put up a picture

of a shaper vise that had a pair of bosses to support the rear

section of the vise. I thought it looked like a good idea to

reduce flexing of the vise body. I decided to try and measure if

there was any flex when taking a light cut. I mounted the DTI

magnetic base to the side of the table and placed the stylus under

the vise. I then cut the surface of the test block again. What I

saw convinced me that I need to bolt the shaper to the floor. The

DTI needle was bouncing between about a half and full thousandth.

I took a couple pictures that seem to show that there could be

some flex, but I don't think that's what the DTI is showing me. It

is more likely that the needle is bouncing due to the fact that

the shaper is rocking on each stroke and the DTI needle is

bouncing rather than reading flex in the vise. I won't be able to

confirm this until I secure the shaper to the floor.

Time to wrap up

this installment. I am close to accomplishing the goals I set when

I took my first cuts and found that the shaper wasn't as accurate

as I had hoped it would be. I think I have been successful in

helping this shaper produce a little more accurate work as well as

taking care of a couple problem areas that I found. The shaper now

runs as I figure it should and produces fairly accurate cuts. The

next projects are to bolt the shaper to the floor and to try and

recreate the missing ball handle that is used to lock the ram

position. As far as the ball handle is concerned, my shaper

currently has a single nut in place of the missing ball handle. I

posted a message on the Yahoo Metal Shaper group asking for the

dimensions of the handle and a nice gent in Washington state

supplied me with the information I needed. All I need to do now is

to build the radius turning attachment for my lathe so that I can

make the ball handle. Sounds like fun to me.

| Shaper 1 |

Shaper 2 |

Shaper 3 |

Shaper 4 |

Shaper 5 |

Shaper 6 |

Shaper 7 |

Shaper 8 |

Shaper 9 |

© Fager November 9, 2015