|

Grizzly

G3103 Repairs

January 24,

2010 through March 30, 2010

Although I continue

to improve the quality of the mill-work I produce, I got to be

less

and less satisfied with the tolerances I could hold with the Grizzly

G3103 mill. In early January, I finally decided to

attempt to rescrape the mill. I've been working up to this project for

a long time and think I have acquired the tools and the knowledge to be

successful in improving its accuracy.

After spending a

year rescraping the DoAll surface grinder,

I decided that I would afford myself a power scraper. Hopefully

this would speed up the next big job a bit. I purchased a used

Biax 7 ELM

and got familiar with it by scraping a small surface plate and a couple

angle blocks. Using the power scraper is a whole different

process and being able to adjust the stroke length and speed allows you

to change the pattern you leave on the surface you're scraping. I'm

impressed with what I am able to do so far and know that the more time

I spend using the tool, the more comfortable I will become in using

it. I am a bit surprised at how sore I get from using it. I

figured it would be a lot less tiring than hand scraping. That's

only partially true. It still tires the muscles to hold the

scraper so that it makes good contact for hours on end.

One of the last

items I wanted to have before starting the mill rescraping project was

a cross check level. A

cross check level allows you to view the deviation from flat on two

planes simultaneously. This is a nice tool to have when you're

leveling a machine tool, though I really wanted one to use with my shop

built King-Way style way checking tool. Using the cross check level

with the King-Way tool allows you to see the deviation between the two

ways in both relative height (across the ways) and tilt (along each

way) as you move the tool from one end of the ways to the other.

With a single vial, you can only read one plane or the other for each

pass.

The job of making

the level

was pretty simple. As I had done when I made my 6" precision

level

(for

use where there was limited room), I purchased a couple

level vials that are

replacement parts for the Starrett 199A level. I also bought some

cast (ductile)

iron for the body and brass tube and bar stock for the vial

holders. The T shaped body was cut from an eight inch diameter,

two inch thick round. I milled channels for the vial holders,

then spent a week heating and cooling the body to relieve the internal

stress. After a number of heating and cooling cycles, I machined

to top and bottom flat, then heated and cooled the base a couple more

times. After each cycle, I checked for warpage. Finally, I

ran the body through the surface grinder, then scraped the bottom

surface. It took about 10 scraping cycles with the Biax to get

even coverage of bearing points and then another twenty-some cycles

with a hand scraper to bring the count of bearing points up to 30 or

more per square inch. I've checked the flatness over a couple of

months and there is no sign of warping. I still need to build

the adapter to attach it to the lathe tool, but for now it would help

with leveling and scraping the mill.

Now that I had all

of the tools

that I thought I would need for this project, I had no excuse

not to get

started.

The first step in

hopefully improving the accuracy of the mill was to measure the mill in

its current state to see how far out of square it was and to give me an

idea of what I needed to accomplish. I started a log book and

began to enter the measurements of the mill. Using my assortment of

levels, straight edges and my K&E autocollimator, I leveled, then

mapped the ways of the mill. This would give me a starting point

for making the mill square.

During the couple

years that I have had this mill, I've complained about the Y axis the

most. With a level on the table and the saddle close to the

column, the level's bubble would show one side of the table high.

When I cranked the saddle out and away from the column, the bubble

would move, showing the other side high. We're only talking about

a few thousandths of an inch, but this was one of the things I

wanted to fix. I haven't heard of any other 6 X 26 mill owners

complain of this, but I don't know how many people have checked for it

either. I came to the early conclusion that the twist I have

found

in every axis (X, Y, and Z) is probably due to the castings not being

aged before and during the machining process. After the ways were

machined, the castings warped and twisted. There's no other

explanation I can think of that would cause my straight edge to touch

on the right rear and front left of a single way. Add to this

that the other way of the same axis shows a similar pattern when

printed with a blued straight edge. So my project is to map out

how much twist I have and try to scrape it out.

I started my

measuring by leveling the mill using the mill's table as the reference

plane. I then measuring the displacement from level of each of

the ways with the autocollimator. After that, I removed the table and

checked the top saddle ways for level. I then re-leveled and took

another set of measurements. I then removed the saddle and took

my measurements again. Unfortunately, there was a difference in level

between

each way in each axis. This wasn't going to be an easy measuring

or scraping

job.

To measure the

spindle plane, I added a 1"

diameter, one foot long precision bar in a 1" end mill holder and put

this

into the R8 spindle taper. Using a quarter wave, front surface

mirror and

my K&E autocollimator, I

checked the alignment of the spindle to that of the Z ways in both the

fore and aft and side to side planes. The closest match was

between the spindle and the right Z way.

These two planes were only out by a couple thousandths over a foot of

distance. The worst alignment I found was measuring the top ways

on the knee where the left

way sloped one direction from the column and the right sloped the

opposite direction. At this early stage, I thought that this was

caused by warpage in both the column

(Z ways) and the knee itself being a bit twisted. I learned later

that this was only partially true.

Having read

"Machine Tool Reconditioning" by Edward Connelly, I knew that I needed

to designate one surface as the master surface that all other surfaces

would be aligned to. I also knew that I wanted to scrape as

little as possible while still achieving a square machine. Since

the mill had no true 'master surface'

to start with,

I would need to create it. The position of the surface I would

choose needed to be one that allowed me to change the

existing angles of the

mill's ways the least while allowing a precise 90° angle between

the Z ways and the connection (mounting area) that holds the mill's

head assembly..

I removed the mill

head from the machine and checked the horizontal

surface that the head swiveled on. Again using both the

autocollimator and levels to double check each surface, I leveled the

mill on its adjustable feet using the horizontal head connector

surface. I

then checked my Z ways for squareness. They were off, but one of

the Z ways was pretty close to square with surface on the top of the

column. I decided that I would start scraping the connector

surface. My goal was to create a plane that was 90° to a plane

somewhere between the current plane of the Z ways that now

sloped in opposite directions. Once I had the Z ways scraped

flat and in a single plane, I would revisit the circular connection on

top of the column and make sure it was as close to 90° from the Z

as possible.

|

|

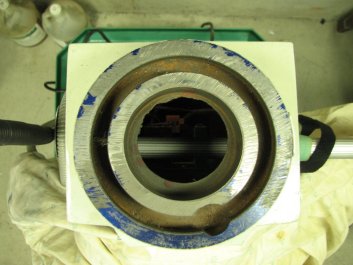

| The

top

of

the

column

showing

how

few

areas

(blue)

made

contact

with

my

small

surface

plate. |

I

used

the

machine

adjusters

to

level

the

column

top

so

that

the

Z

ways

aligned

to

their

best

position. |

Leveling the mill

is not a trivial task when you don't have a single flat axis to work

from. I had to level to a position that was 90° from the

imaginary plane between

the two Z axes. I.E., one way titled toward me by a small amount and

the other way tilted away from me. Trial and error and some

guessing was the only

way to accomplish this. However, I find that in leveling a 4

legged tool, it helps to adjust the leveling feet

diagonally rather than side to side and front to rear. I needed

to end up with the fore and aft inclination of the

Z axis vertical as well as having the left / right inclination

vertical. I ended up with a plane where the difference from 90°

vertical on the two column (Z) ways is about 0.06° in opposite

directions. In other words, one way is 89.04° and the other

is 90.06°.

The above angles

are in the fore to aft position. For the left to right

inclination, I had it a little easier. The small ledge on the

outside of each of the two Z ways were milled pretty close to the same

on either side. Using the box level, then checking my angles with

the autocollimator, I positioned the adjusting feet to make these two

surfaces as close to vertical as I could. I split the difference from

vertical so that I would be removing approximately the same amount of

metal from each way as I scraped.

|

|

| Scrape

and

check,

scrape

and

check. Repeat, rinse, and repeat again until it levels. |

Some

period

of

time

later,

we

have

a

scraped

flat

and

level

surface.

A

good

place

to

start

from. |

Once the mill was

leveled, I started scraping the two cast iron rings that make up the

mounting area for the head. Between the inner and outer ring is

the tee-slot used to capture the bolts that hold the milling head

assembly to the column. There is a circular enlargement to the tee-slot

in one section to allow the bolts to be removed. As I scraped, I

checked my progress by alternating

between my hand-scraped small cast iron surface plate to

check for flatness and testing with my 0.0002" resolution box level to

keep the surface level in both planes. Before I began scraping, I

used a crosscut file

to quickly remove stock from the front side of the column mount, then

switched to a hand scraper. The factory

surface on this critical connection was pretty rough and my flexible

blade kept catching on the large ruts, so I changed to a heavier, less

flexible blade and powered through the rough areas. This

connection is critical to not only get flat, but also have a large

enough number of bearing points to allow the mill's head to swivel

smoothly. It's important that the head

stays in a single plane as it swivels from left to right so there needs

to be enough bearing points to facilitate a good connection between the

two pieces. None of this was provided by the factory finish.

On completion of

the top column mount, I now had my one flat surface to work from.

I decided to move on to the milling head assembly. This assembly

is made up of four sub-assemblies. Just above the column mount is

a "T" shaped connection that allows the head assembly to swivel left

and right. This piece is cast iron and has a flat base on the

bottom with a protruding 3.150" cylinder that fits down into a

similarly sized hole in the column mount. To mount the milling

head in the front and the motor plate to the rear, there are two more

circular flats with protruding cylinders. These circular flat

mounts with cylinders are a bit smaller in diameter than the one on the

bottom and allow both the milling head and motor plate to rotate about

the horizontal axis. Because each of these connections has the

protruding cylinder in the center of a surface that needed to be

scraped flat, it presented a problem. I couldn't just lay the

surface on a flat plate to check flatness without boring a hole in one

of my surface plates. I actually considered this as I have a

couple import 9" X 12" granite plates that are still in their shipping

boxes, but since all three cylinders are different sizes, I'd have to

bore the hole three times to check and scrape all three surfaces.

I decided this would be more work that it was worth. Instead, I

used three 3" X 12" granite parallels I had match ground on my surface

grinder. I laid these in a star configuration with the cylinder

from the "T" connection in the center of the three parallels.

While the three parallels didn't quite cover the entire circular flat,

it covered most of it. I covered the three parallels in Prussian

blue and used them as my surface plate with a hole in it. After

each marking and scraping operation, I set the "T" so that the area

that didn't get marked in the previous cycle got marked in this

round. I am not sure how they originally machined the connections

of the T shaped piece. There was a slight

depression around where the cylinder stuck out from the flat portion of

the mounts. I will say that when I set the connector up on my

surface plate and checked the two side surfaces with my master square,

they weren't too far from 90°. No they weren't dead nuts on,

but they were closer than I expected.

I scraped the

bottom surface flat, then blued up the top column connection and

checked to make sure I had good contact between the "T" and the column

mount. Once I was satisfied with the contact while the "T" was in

its usual straight ahead position, marked by zero degrees on the scale

attached to the "T" and column, I cleaned the blue from the "T" and

checked other settings. At each increment of 10° in position,

I checked for good contact and also used my box level to make sure that

the surface where the milling head attached remained level.

With all three of the "T" connections scraped, I still had two surfaces left to deal with on the head assembly. The motor mounting plate and the milling head. There wasn't a lot to do on the motor plate as it is not critical if the motor is not aligned to seconds of arc. I scraped it to good bearing and made sure that it stayed close to level as I rotated the plate through its range of possible positions. Setting up the milling head was a different story. My goal in working on this mill was to improve its accuracy. Getting the head to be dead on 90° to the table meant that this connection, as well as the column to "T" and the column to Z ways had to be as perfect as I could accomplish. In order to scrape the proper angle into the mill head connection, I needed to find the center line of the R8 internal taper in the spindle.

First, I removed

the belt guard cap screws, then removed the spindle

pulley. The milling head can then be removed from the

guard. I inspected the taper and went over it with a slip stone

to make sure there were no burrs. I had purchased some new ETM

brand end mill holders that checked out to be pretty concentric and

mounted

some precision shafting in place of an end mill. This would, in

theory, extend the center line of the R-8 taper out to where I could

check it

against the mounting flange on the surface plate.

It worked pretty

well. I first set up with my new 3/8" end mill holder and a piece

of 3/8" drill rod about a foot in length. I cleaned up the flange

a bit with a hand scraper as there was some ragged edges near the

bottom edge of the flange. I cleaned and polished my Starrett

surface plate and carefully laid the head, flange down, on the

plate. I then used a 'half-tenths' indicator to check for

parallel along the drill rod. This would show me the relationship

between the R-8 taper and the head's mounting flange. As I

measured from end to end of the drill rod, I also rechecked with the

spindle turned in quarter turn increments. The end of the drill

rod was low by 0.012" at the best and 0.016" at the worst compared to

the section of drill rod just outside the end mill holder. That's

a lot. I was also showing 0.004" run out at about 12 inches from

the end mill holder.

There was only 0.0005" run out just outside the end mill holder.

I swapped a 7/8"

collet for the end mill holder and used a 12" piece of 7/8" precision

shafting. I got almost identical results. This told me that

there was a slope of about 0.001" per inch on the head mounting

flange. Since the flange has a diameter of about 5 inches, that

meant that I needed to remove about 0.005" from the top of the flange

and nothing from the bottom. It took about 15 cycles of

measuring, marking and scraping to get the flange parallel to the

precision shaft. It took another 15 to 20 cycles to get a nice bearing

surface on the circular area.

Once I was

satisfied with the surface of the milling head and head connection, it

was time to lay

the mill on it's back. I had considered scraping the Z ways with

the mill in a

vertical position, but this would make checking the plane of each way

much more difficult. It would be easier to lay a level on a

horizontal surface than to hold a box level to a vertical surface. In

order to

position the mill on its back, I would need to

support it so the Z ways would be held in an exact horizontal

plane. Again, the mill needed to be horizontal in both the front

to rear and side to side planes. As it turned out, I had a couple of 4"

cylindrical pieces of steel that were very close to the right height to

prop up the end with the head connection. I leveled the Z ways

length-wise, then shimmed each corner to get the side to side plane

level.

With the box level

measuring the head connection plane, now vertical instead of

horizontal, I made sure that the plane was parallel to the force of

gravity. I then mapped out the Z ways using the box level. The left way

was sloped up at the base end and a couple thousandths low in the

center and at the head connection end it was higher than the center,

but lower than the base end. The right flat way was sloped up at

each end and low in the center, though, as with the left, it was higher

on the base end than the head end. Each of the two ways were

about 22" long and 2" wide, so I could use one of the granite angle

straight edges that I had made as a scraping master. Because my

goal was to make the ways perpendicular to the head connection, as well

as flat in both the length and width, I started out printing each way

from the Prussian blue coated granite master and guessing at how much

material to remove to achieve all my goals. Because it was

necessary that the two ways were in the same plane, I

would need some sort of jig to keep the ways the same height and even

with each other. It could be done with a couple of parallels to

lift the box level over the raised area between the ways, but using

the parallels introduces more room for error as there are more pieces

to deal with. However, if I scraped the knee Z ways flat using my

surface plate, I could use the knee as a template. Between the

two setups I would be able to scrape the plane of the Z ways pretty

close to true.

I blued the master,

printed both Z column ways and scraped about 12 cycles before I started

getting

sore from working on the concrete floor. Working on ways about 8"

off the floor wasn't going to allow me to produce the best

finish.

I solved the issue by placing an old Formica counter on top of the

mill's base, then hoisting the mill column casting to rest on it.

I used the

same steel cylinders to block up the connection end and shim stock to

level the base. The ways were now about 30" from the floor.

Still a bit too low for my liking, but a whole lot better than working

on the floor. I had switched to the Biax 7ELM scraper after about

the third round of scraping - just enough time to figure out where the

problem areas of the ways were.

As it turned out,

near the vertex of the dovetail ways, on the wide flat way, there was

an

edge that stuck up higher than the rest of the ways. This was

caused by the ways of the knee not contacting that section of the way

as the knee was moved

up and down the column. Because it was close to the vertex,

this area was

not able to be scraped easily with the power scraper without the chance

of

putting dings or gashes in the angled way. To scrape this area I

switched to a 1/16" thick carbide bladed hand scraper that had been

further thinned by a couple years of sharpening the sides of the blade

with diamond

paste. A couple cycles of scraping had the edge knocked down to

the level of the rest of the way. By about cycle 16, I was

starting to get points in the mid-section of the ways. I was

still high on the base end, but it was coming down cycle by

cycle. I had stopped scraping the very end by the head connection

side of the ways once I had about a two inch section of the end of the

ways that were flat and showed points all across the width of each

way. Leaving this end unscraped would effectively lower the

opposite end and bring the way into being perpendicular with the head

connection.

After I had bearing

points showing along the entire surface of each of the flat Z ways, it

was time to make sure that the ways were in the same plane. As I

said before, I would accomplish this by using the knee as my

template. However, first I needed to check the ways that

contacted the column on the knee. Back to the surface plate. The

knee was as bad as everything else I had checked. With the ways that

contact the Z ways of the column sitting on the surface plate, I used a

"L" square to check to see if the Y facing ways were at a 90° angle

to the plate. They were close, but one was about 91° and the other

was 89°. More twist. I then checked what amounts to the

height of the Y ways by placing a piece of 1/2" drill rod in the vertex

of the flat and angled ways. and using the "L" square to see if it was

perpendicular to the surface plate. This measurement was way out.

(I knew this from using the mill.) The knee leaned to the right.

To visualize which plane this is; you're above the mill looking down on

it. The connection for the head assembly is in the center of an

analog clock face. 12 o'clock is behind the back of the column

and the mill's table runs from 9 o'clock to 3 o'clock. The knee would

normally extend toward 6 o'clock, but in this case, the Y axis points

to between 6 and 7. It faced to the left of 6 o'clock by

an

amount equal to 0.0045" over 6". To make the knee point at a

right angle, I would need to remove metal from the knee's right Z

way. Since the crank end of the knee was not only facing a bit

left, but also a couple thousandths lower than the column side of the

knee, I

would need to correct the Z ways on the knee in two planes.

Fortunately this isn't

as hard to do as it is to describe.

I made a jig to

hold the knee with its Z ways facing up and clamped it to my cast iron

saw table. Out came the tools and I ground, filed and scraped for

two evenings to remove enough metal to make the knee sit on it's Z ways

and be close to perpendicular to the table in all directions. Or close

enough

for now. All I really needed at this point was for the knee to be

perpendicular to the surface plate and for there to be enough bearing

points that I could use it to check the plane of the Z ways on the

column. Removing about 4 thousandths from a way - even a short

one like the Z on the knee is a lot of metal when scraping. I

didn't even try. I started with a belt sander and some 60 grit,

progressed to a bastard file, then the Biax, and finally hand scraped a

couple cycles. In between every few cycles of each tool, I

cleaned up the knee with a shop vacuum and alcohol wetted towels and

put it back on the surface plate. I didn't want to remove too

much material. Once that the mill is back with the column in the

vertical position, I will add the gib and check the Y knee ways for

level and being parallel. Eventually the crank end of the knee will be

a small amount higher than the column side. This will allow the

knee to take the weight of items on the table and the forces subjected

to the knee in machining without sagging. The specs I've heard

amount to about a half thousandth high at the crank end.

When the knee was

square, I blued its Z ways, then lifted it on to the column which was

still lying on its back. I slid it along the ways; from the head

end to the base end and looked at the pattern it left on the column's Z

ways. Amazingly, the pattern was very close to the same pattern I

saw when I printed each way separately with the granite master.

If I had seen markings on both outside edges of the ways, or both

insides, or one of each, I would have had to adjust the column ways to

bring the two of them into a single plane. As it was, I could

continue my scraping on the column Z ways, confident that the ways were

flat with each other.

I did encounter one

issue with the knee to column fit. I had removed enough material

that the vertex of the non-gib side of the knee was touching the

machined groove that is cut in the vertex of the column Z way.

There are three choices here that I can think of. Add a piece of

Turcite B to the angled

way of the knee ways to build them up, or cut the tip of the vertex of

the knee ways down, or deepen the channel at the vertex of the column's

non-gib side flat and angled Z way. As I looked at the position

of the knee on the column, I saw that the knee was closer to the

gibless side of the ways, than to the gibbed side. I could deepen

the channel of the right column Z way and shorten the vertex of the

knee ways without running out of width on the gib side of the column's

Z ways. I had read about this happening in Connelly's book and

knew that it was a real possibility because of the amount of metal I

needed to remove to straighten out the knee, but having the knee square

with the column was more important than having the ways shifted a bit

to the left.

By the beginning of

March, I was getting close to having the Z ways finished. I was

now able to measure the Z on the column with my 2 ten-thousandths

sensitivity box level and the bubble never traveled further than 4

lines. Eight ten-thousandths difference between the lowest and highest

spots on the ways. The scraping goes a lot slower at this stage

since there are many bearing points to scrape off in each cycle.

Also adding to the lack of speed is that the straight edge needs to be

spotless before you can add the Prussian blue and make a print on the

ways. If you pick up a fleck of metal in the blue, you won't get a true

print or maybe no print at all.

I was also checking

the column Z ways by bluing the knee and setting it in position, then

sliding it along the column. I had my box level on the crank end of the

knee and in addition to watching the bubble in the level, I watched the

markings left on the column ways. In the early scraping cycles,

the bubble moved from the left, to the right as I traversed the ways.

It moved much less now, but I still had about a half ten-thousandth to

go. I had decided I would stop when I could keep the bubble

within 1 line to either side of the box level and I had full coverage

of bearing points. This would be about a half of a graduation on the

Starrett vial. Trying to chase after no movement of the level bubble

was

not something I was planning on doing - even if it was possible.

With 2 ten-thousandths per 10 inches sensitivity on the box level,

almost everything I did changed the bubble position. Whether I

touched the level with a warm finger, breathed on it, didn't position

it in the exact same spot, you name it and the bubble moved. I

had already improved the Z ways to be much more accurate than they were

when the mill arrived a few years ago. The knee now moves with the

touch of

a finger, rather than a stiff push, so I know it is going to be a great

improvement. My biggest question is whether the mill has finally

settled in and if I can expect the new accuracy to last. I tend

to think that if the casting does continue to settle in, it will do so

to a much lesser degree than it has done up to this point. I am

hoping so, anyway. I have a whole lot of time invested in this mill now

and I'd hate to think that it would twist like a pretzel after all the

scraping I've done.

March 13, 2010

This afternoon I figured I'd scraped the column enough. With the

box level set up on 2 pieces of 7/8" diameter shafting, I could move

the level

from the base to the top and the most the bubble moved was less than 1

division. I'd been at this point for 2 days and the only thing I

was accomplishing by scraping was more bearing points. Not to say

this is bad, because it isn't. It's just that this is about as

good as I am going to get it without driving myself into boredom.

I'm ready to move to the next axis.

Using my engine

hoist, I lifted the base and column assembly and while it hung in the

air, I checked and cleaned the base and mounting points. I set it

on the stand and bolted it down, being careful to torque the bolts

incrementally and to about 75 foot pounds. I then leveled the

column using the box level on the Z ways. The difference between

trying to level it before and after scraping the ways was drastic. One

half hour later and I was close to dead level. The connection for the

head

was right on level in the front to back plane and about 1/2 thousandth

high on the left. This was due to having to make an adjustment to

the left Z was dovetail. I scraped the column to head connection

for a few hours after dinner and called it a successful day.

March 18, 2010

I started working on fitting the knee a couple days ago. When I first

tested it

on the Z ways, I found that my scraping on the Z ways side of the knee

had been a success. The knee now is aligned 90° to the face

of the

column. That is to say that if you looked down on the mill from above

the knee is in the 6 o'clock position. As I've said, it used to be

somewhere between

6 and 7 o'clock. Not exactly square with the column. The next

step was to measure for tilt between the two top ways of the knee. This

would be the Y axis ways and I am measuring the height difference

between the left and the right. The left is low. It started very low.

About 12 thousandths. That is a lot for ways that only have 5 or

6 inches between them. I also saw this same measurement while

checking the knee on the surface plate. It's nice to see that my

measuring was accurate. On the other hand, I am pretty

disappointed that the knee is tilted with the right side higher than

the left. One would have thought that this would have been caught

by some sort of QA process at the factory. If the saddle above

the knee and table above that are all perfectly symmetrical, the left

end of the 26" long table would be 20 to 30 thousandths low. I've

measured it and it isn't, so there is something else messed up that I

haven't gotten to yet. Lovely.

On the surface

plate, I also saw that the

tilt between the Y ways close to where they meet the Z ways, to the end

where the crank is was a couple thousandths low at the crank end.

As I said before, this measurement should actually be a fraction of an

inch

(couple ten-thousandths) high. Now that I measure them with the knee

attached to

the mill, I find that one side is 3 thousandths lower at the crank and

one side is 1 thousandth lower. This (I'm guessing) is because

the knee is twisted. As I

remove metal from the bottom of the angled right knee Z way, the height

of the left Y way will increase. Once I get the left to right

tilt out of the knee, I'll get back to scraping additional metal from

the top of the knee Z ways, which will raise the crank end of the knee

in the Y axis.

In a couple of days

scraping, I have decreased the left to right twist from 12 to 2

thousandths. To keep the slope of the angled way constant, I am

using two templates to print from. The first is my 12" granite angle

template. This template has a 45° angle with a very sharp

vertex. This allows me to blue along the slot at the vertex of

the two ways that make up the dovetail way. I am also using one

of my first scraping projects, made about 4 plus years ago, when I

first got the bright idea to rescrape the mill. The template has

a 55° angle and is scraped on 3 sides. I used the Y axis

dovetail ways of the Grizzly mill to create the cast iron template and

it turned

out very nice. It also took the better part of a month to scrape,

but I was a lot slower then than I am now. By using the pair of

templates, I'm confident that the angled way will turn out flat and at

the

correct angle to fit nicely with the column Z ways. Because I am

removing metal from the angled way, the distance between the two angled

ways is increasing. It is now getting tough to measure the

progress

accurately as the gib no longer fits with just some shim stock behind

it. By scraping the angled way on the right side bottom of the

knee, I am purposely changing its angle in order to raise the left side

of the knee. This in turn changes the angle of

the gibbed side clearance. To help me get the knee snug on the Z

ways, I've needed to add more thickness to the bottom of the

gib.

This is trial and error work, measuring with my shop set of gage

blocks, then shimming the gib with different thicknesses of shim stock

to match the measurements. This is

turning out to be very time consuming, but it's the only way to try and

ensure that I don't scrape too much off of the angled way. Even so,

from the top

left of the knee being 12

thousandths low to being only 2 thousandths low went pretty quickly.

Even

quicker once I got a handle

on how the gib measurement was being changed. However, from 2

thousandths to zero

tilt is going to require many test fittings to make sure I don't go

past zero. Once I get within a few ten-thousandths, I'll start

scraping for removing some of the "drop" from the crank end of the knee

at the same time. This should

prove to be an interesting task, but once this is done, the rest of the

scraping - the saddle and the table - will be pretty straight forward -

or so I am hoping.

Well, so much for

hoping that the saddle scraping would be straight forward! The saddle

turned

out to be the worst piece of the mill. When I went to measure the

saddle so I could use

it as a template to keep the Y axis ways of the knee parallel and

level, I found out a couple things. First, the saddle had been

ground with what appears to be a hand held grinder to adjust its fit.

Second, the fitting - if you want to call it that - had been

done so that the saddle was a different height on the left than it was

on the right. Not just a little bit, but about 20 thousandths. It

appears that someone knew that the knee was not sitting straight and

instead of

fixing it, they ground the saddle at an angle so that the table would

appear level. The gouges in both sides of the saddle ways are so

deep that I doubt that I will be able to get them all out without

making the saddle too thin where the angled ways meet the flat ways.

However, seeing as how the saddle ways were only contacting the knee

and table ways in a very small area, even with a couple deep gouges

left after I finish scraping, the accuracy and rigidity are going to be

much better than it was. Here I have been trying my best to blame

the poor fit on warpage, but that's not the case with the saddle. The

only way to describe it is shoddy workmanship.

It could be that

this mill is an isolated case of a "bad unit" making it through the

manufacturer's

usually exemplary quality control process. However, based on what

I have seen with this mill, it appears that rather than fix the problem

with the knee not fitting as it should have, they did whatever it took

to get this one out the door. I just happened to be the lucky guy

who got it.

So, my task becomes

reworking this saddle so that the following conditions are met:

|

|

| The

chuck's

been

cleaned

and

the wheel dressed. |

The last passes on the Y ways have been ground. |