Adding Temp Monitoring to the

1800T

Click on smaller images to enlarge.

Since

I now had the 1800T up and running a dual boot of redhat and Win2k, what

was there to do except take the thing apart. From looking at the

Compaq PDF on connector pin outputs, it appeared that the docking station

connector would have all of the connections I needed to grab the gameport

circuitry and hook in my temperature sensors. All I would need to

do is take the 1800T apart and do a little soldering. Well, I was

partially right.... Since

I now had the 1800T up and running a dual boot of redhat and Win2k, what

was there to do except take the thing apart. From looking at the

Compaq PDF on connector pin outputs, it appeared that the docking station

connector would have all of the connections I needed to grab the gameport

circuitry and hook in my temperature sensors. All I would need to

do is take the 1800T apart and do a little soldering. Well, I was

partially right....

To get started, I purchased a nice set

of Torx screwdrivers. All I had in Torx were a bit on the worn side

and I wanted to make sure that my new laptop still looked new after this

ordeal. The tools required for disassembly are minimal. A T8

Torx driver, a Phillips driver - I used a #0, a flat bladed screwdriver

- again a small one, a 5 mm nutdriver or socket and some patience.

Be advised that the laptop's case is what we in the auto industry used

to call "precision plastic." "Precision" was used as a joke to describe

parts that either didn't fit together well or fit together in such a way

as they wouldn't come back apart. In the case of the Compaq, the case fits

together well. Almost too well. Some gentle persuasion is required

to get the pieces apart. The PDF is pretty clear on the order of

disassembly and which way to "force" the pieces apart, but you need to

exercise a certain amount of restraint in how much pressure you use.

I printed the PDF file for easy reference.

I also read through the entire procedure a few times to try to familiarize

myself with the steps and made notes on things that weren't clear to me.

Better to be aware of the areas that I thought that I might have problems.

To keep from scratching the surfaces, I

worked on a towel. I also set up another towel where I could place

the items I removed from the computer in the order that they were removed.

This may seem like overkill, but I tend to get interrupted by one thing

or another and I wanted to be darn sure that I knew where everything went.

Nothing in this process is that dificult,

with the possible exception of soldering to the tiny "legs" on the motherboard.

However, if you have to question yourself whether you should be attempting

this project, you probably shouldn't. |

The takedown begins

The

disassembly started with the removal of the battery and removing the first

5 T8 screws (4 long and 1 short) from the bottom of the case. Flip

the case back to right side up and slide your fingernails into the center

of the seam that runs horizontally along the front of the case. Lift

upward and toward yourself until you hear the first "pop" of the plastic

retainer catches coming loose. The pop that the plastic makes when

it releases is guaranteed to send a chill down your spine, no matter how

many times you have heard it before! Move your nails an inch or so

away from the center and repeat lifting. Repeat until the top cover

comes loose. Disconnect the ribbon cable from the bottom half of

the case and lift off the top cover. The

disassembly started with the removal of the battery and removing the first

5 T8 screws (4 long and 1 short) from the bottom of the case. Flip

the case back to right side up and slide your fingernails into the center

of the seam that runs horizontally along the front of the case. Lift

upward and toward yourself until you hear the first "pop" of the plastic

retainer catches coming loose. The pop that the plastic makes when

it releases is guaranteed to send a chill down your spine, no matter how

many times you have heard it before! Move your nails an inch or so

away from the center and repeat lifting. Repeat until the top cover

comes loose. Disconnect the ribbon cable from the bottom half of

the case and lift off the top cover.

In the first few sections of the disassembly

PDF, there are some pages on the connectors used in this laptop.

These are pretty standard fare, but much different than what you're used

to if you've only dealt with desktop systems. The connectors are

female only with the male side being just the ribbon cable itself.

The exceptions to this are the connector for the flat panel screen, which

has both a male and female connector and the power connectors which use

standard wire. It is advisable to pay close attention to the instructions

on how the connectors come apart before you start yanking on things.

I won't go into as much detail for the

rest of the disassembly, but the first step can make or break you.

Literally. This cover was tight on my laptop and I was fearful of

breaking something. Once I was able to get a look at how the plastic

latches worked, the next time I took it apart it was easier. (Next time?

Yes, this was the first of MANY times I have had this box apart.) |

That's a heat sink?

Once

the touchpad cover has been removed, the keyboard lifts out. There

are no screws holding it. Lift it up a little bit and you'll see

the connector on the right. Unplug it and the keyboard lifts out

- up and toward you. Once

the touchpad cover has been removed, the keyboard lifts out. There

are no screws holding it. Lift it up a little bit and you'll see

the connector on the right. Unplug it and the keyboard lifts out

- up and toward you.

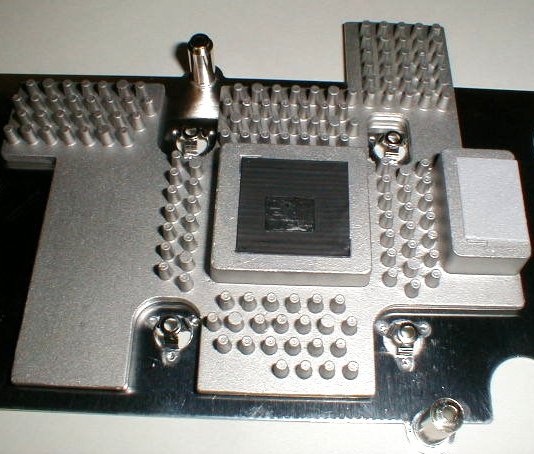

Once the keyboard is out of the way, you'll

be looking at a flat piece of sheet metal with six T8 screws (2 long and

4 short). This is the support for the keyboard and the hold down

bracket for the heat sink. The 4 screws in the center clamp the heat

sink to the processor. The two additional screws locate the

assembly on the motherboard.

In hindsight, it would probably be best

to work on the 4 center screws first. Loosen them a bit at a time

in a circular fashion so as to take the tension off the processor evenly.

Once you have these out, remove the two remaining screws. |

Why

the care in removing the 4 screws? Because like many manufacturers,

Compaq chose to use a rather rough heat sink casting and took care of "making

it flat" by using thermal tape. This thermal tape compresses and

does a pretty good job of filling in any voids in the rough casting; however,

it does not like to be reused. Being very gentle with the removal

of the heat sink may give you a better shot at reusing the tape.

I had the sink - with tape - on and off a few times without noticeably

damaging it, but I knew I would be stripping it off in favor of a better

interface before the project was through. You may opt to keep your

tape intact. Why

the care in removing the 4 screws? Because like many manufacturers,

Compaq chose to use a rather rough heat sink casting and took care of "making

it flat" by using thermal tape. This thermal tape compresses and

does a pretty good job of filling in any voids in the rough casting; however,

it does not like to be reused. Being very gentle with the removal

of the heat sink may give you a better shot at reusing the tape.

I had the sink - with tape - on and off a few times without noticeably

damaging it, but I knew I would be stripping it off in favor of a better

interface before the project was through. You may opt to keep your

tape intact.

Notice the 4 raised areas of the sheet

metal. These are where the short screws attach to hold the sink to

the processor. The 4 raised areas actually act like springs to even

out the clamping pressure on the processor. These can be pushed down

a bit (made flatter) to increase the tension on the sink to processor bond.

To the right of the square pedestal that

mates to the processor is a rectangular casting that has some white foam

on it. This hump sits atop of a chip on the motherboard. I

would have guessed that thermal tape would be used here to help dissipate

the heat from the chipset, but if this is thermal tape, it is unlike any

that I have seen (and I have seen a few types...). It just appears

to be foam to help support the casting. Whatever, it will get thermal

tape before I am through :-).

One last comment (for now) on the sink.

I am a bit bummed that I didn't end up with a laptop with some tricked

out heat pipe assembly on it. Yes, I know that they're more expensive

to produce, but with my interest in heat pipes, it would been fun.

This heat sink is, well, kind of boring.... |

Getting down to the basics

I'll

stop with the blow-by-blow account of the disassembly, as the rest of the

process is pretty straight forward. According to the instructions

from Compaq, here's the whole procedure with page numbers. I'll

stop with the blow-by-blow account of the disassembly, as the rest of the

process is pretty straight forward. According to the instructions

from Compaq, here's the whole procedure with page numbers.

1. Prepare the Notebook for disassembly

(pg 10).

2. Remove the Palmrest cover with

TouchPad (pg 13).

3. Remove the keyboard (pg 16).

4. Remove the heat sink (pg 23).

5. Remove the button board cover

(pg 17).

6. Remove the Internet switch board

(pg 21).

7. Remove the display panel assembly

(pg 34).

8. Remove the hard drive (pg 25).

9. Remove the upper CPU cover (pg

37).

10. Disconnect the LCD DisqPlay module

cable from the system board (pg 28).

11. Remove the modem (pg 24).

12. Remove the CD, CD-RW, or DVD drive

(pg 31).

13. Remove the fan assembly (pg 38).

14. Disconnect the diskette drive cable

from the system board (pg 43).

15. Remove the voltage converter board

(pg 44).

16. Disconnect the speaker assembly cables

from the system board (pg 46).

17. Remove the system board (pg 47).

Page

51 tells you to "Make sure that the PC card eject button is pushed inward,

and then lift up the front of the system board and pull it forward to remove

it from the chassis." Page

51 tells you to "Make sure that the PC card eject button is pushed inward,

and then lift up the front of the system board and pull it forward to remove

it from the chassis."

This procedure is a little more tricky

than the text would have you believe. On the under side of the mainboard,

in the rear (toward the port connectors), there are obstructions.

One is a bent piece of spring metal that acts as a "ground strap."

There are also a couple of plastic pedestals that serve as receptacles

for screws. The motherboard tends to get hung on all of these.

Moving the board slightly to the left before lifting the front edge helps,

but I found that patience and a lot of wiggling and gentle persuasion were

needed to release the board from these demons.

I've had the board out a few times and

the task didn't get any easier with practice. Walk away from it if

you get frustrated. It will come out... eventually. |

Getting at the connector

| At the step when I had the heat sink removed,

I realized that my original hope of soldering directly to the docking station

connector pins was over. The pins I needed were hidden below the

first (accessible) layer of pins. My only chance for getting access to

the pins was on the bottom of the motherboard, but that the board would

have to come out.

The connector is an 80 pin unit with everything

from video signals to (obviously) the gameport running through it.

It is also pretty small. Small enough that it is hard to get a reading

off of an individual connector trace from the rear of the laptop with my

digital multimeter. Soldering to the legs of the connector on the

bottom of the motherboard was going to be a trick.

|

|