|

After my success with the Fullway and TEC, I started wondering if the addition of a very large heat sink without a peltier attached would draw away enough heat to allow the Celeron to make the jump from 464 to 504. I have had pretty good luck with massive heat sinks in the past and thought that I would give it a try. After rummaging through my collection of sinks, I found that I had nothing large enough to suit me. I did have a 3 pound block of aluminum though.

Not having the proper tools to machine such a thick chunk of aluminum, I made do with a metal cutting blade on my woodworking band saw. This was was a very slow and inaccurate way to cut the fins and the final result was not very pretty. However, it did give me the information I was looking for.

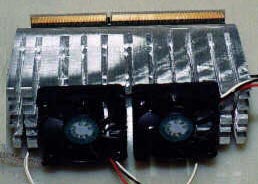

Not very pretty, but big!

After cutting on the aluminum for a few evenings, I had pared the 3 pound block down to a trim 1 pound 3 ounces with a surface area of about 170 square inches. The sink is so big, that with the 10mm fans screwed on, it just cleared the first RAM slot on the BH6. Would this be enough to get the Celeron stable without a peltier attached? In a word, no. While it was better than any non TEC sink I had used in the past, I still suffered random lock-ups. The overall temperatures remained low enough, but the temperature still skyrocketed during the boot process.

Back to Peltiers

I figured that as long as I had spent

the time to cut this monster of a heat sink, I might as well see what kind

of results I got when I added a TEC to it. I had been also wondering

if I might get better results with a larger cold plate. Another night

of cutting and I had all of the pieces for my TEC with the big sink.

.

.

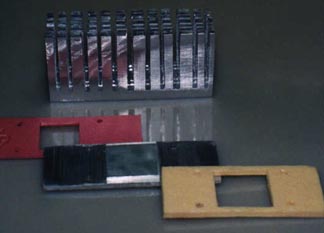

The pieces

I increased the thickness of the cold plate and cut in some pedestals for the TEC and the slug of the Celeron to sit on. The weight of the cold plate went from about an ounce for the original, to 2 1/4 ounces for the new prototype.

I had high hopes for this setup, and was surprised when the Celeron wouldn't even make it into Windows at 2.2 volts. What the heck was happening here? As I switched back to the original Fullway peltier sandwich on the Celeron, I couldn't help but think that in all my playing around, I might of somehow damaged the processor. My fears were unfounded as the Cele promptly booted up into Windows happily at 2.2 with the original Fullway / TEC sink installed.

To try and understand what it was that was causing the difference I started mixing up the parts. I used the original cold plate and the big sink and booted up fine, while the Fullway and the larger cold plate wouldn't make it past the Windows logo screen. I cut another cold plate. This one weighed in at 1.5 ounces. After lapping the surfaces flat and smooth I gave this one a try with both sinks. With this combination I was able to boot into windows as long as the system had been turned off for 15 minutes or so. On a reboot, it would lock up.

Conclusion: for this Celeron running with this TEC, a 1 ounce cold plate works best. More importantly, I have again proven that sometimes dumb luck produces the best results. While this is by no means on the level of Goodyear and the discovery of vulcanization, my first cold plate just happened to be the right piece for the job.

Now that I had the big sink working with

the TEC and the Celeron was again stable at 504, it was time to see if

the increase in mass of the new sink made an appreciable difference in

the temperature of the Celeron.