|

What's New Archives - 2000

|

|

|

|

|

|

I have a couple of new heat sinks on the way and hope to get some new reviews up some time in the near future.

|

|

"I have been reading some of the articles on your website and have a little information I would like to pass on regarding electrical insulation of printed circuit boards.

You used polyurethane, which will work. However, the aircraft industry and the marine industry have been doing this sort of thing for years. We don't use polyurethane, as it can develop micro cracks as it ages (especially in elevated temperature or UV environments). We use silicone RTV.

Normally, this product is procured in ready-to-use fashion by the quart or larger quantities and it is expensive. However, you can make your own quite easily. Get a large tube of clear silicone adhesive and cut it with a solvent (Xylene, Methyl Ethyl Ketone, or Acetone) till it has the consistency of house paint or a little thicker. Then just dip the card in the stuff and let it dry overnight. It will last something like 600 years, is impervious to UV, will not break down from heat (under 300 degrees F), and is not affected by acids or salts.

DO NOT USE ANYTHING OTHER THAN CLEAR RTV!!! The colored stuff conducts electricity with white being the worst offender (full of titanium oxide). One thing about using tape to cover the contacts on the edges of the board. We have discovered that the simple act of pulling masking tape from a roll can and often does leave a static charge on the tape in excess of 6,000 volts. (You might want to stick the tape to the edge of your statically grounded work bench for a few minutes before you apply it to the board's contacts)."

Even though I happen to be fresh out of Xylene and Methyl Ethyl Ketone, ( ;-) ) I do have acetone (which is easily obtainable at paint supply and home centers). It does do a nice job of thinning the silicone and the dried mixture is flexible and looks like it will do the trick. Thanks for the tip.

Cue Cat

If you (like me) are a fan of Slashdot,

then this is ancient news. However, the proliferation of sites and

articles on the subject of the Cue Cat and Digital

Convergence's pathetic attempt to control a piece of hardware that

they have given away for free has become quite interesting. Aside

from the privacy issues that surround this device's intended use, the fact

is - it's a free toy that has some great uses. For those who haven't

heard of the device, it's a bar-code reader. When used with Digital

Convergence's software, it allows you to get more information on products

in specially bar-coded ads from Radio

Shack and other retailers. Unfortunately, it also "phones home"

so DC can compile a dossier of your purchasing interests.

To get up to speed on the subject, try the articles and links from this search of Slashdot and Michael Rothwell's great compilation of things Cue Cat at the FlyingButtMonkeys site.

To physically declaw the cat, try this link.

You gotta love this cat.

Thanks

Thanks for all of the nice e-mail concerning

my father. It's appreciated.

|

|

It's been a busy few months, with my job getting the primary focus of my "free" time. We are working on a web interface for a technical support database and I have been trying to learn as much as I can about the various aspects of ASP, MS SQL, and IIS - as well as some more javascript and Flash to try to make the site as usable and visually attractive as we can make it. I've built a new box to be able to run the database at home. (Heaven knows that no one would want me doing "trial and error" on the production machine!) I have taken a few shots of the assembly of the box and will try to get the story up some time soon. This box is no outrageous overclocker, but a nice cool machine none-the-less.

On a sad note, I lost my Dad on September 11. I'll miss him. His death really brought home the saying "tell your loved ones you love them often, as you never know...."

Lastly, I've been receiving a lot of mail that the links to Waterfall Pro and Rain don't work. You're right. Tim and Yihong Software have vanished from the web. I've e-mailed the personal addy I had for Tim without success, so I really can't tell you what happened or where you can mail checks to register Waterfall Pro. Rain and WFP are still available from a number of sites. SoftSeek for Rain, and Rocket Download for WFP - to name just two. If I come across some more information or if someone knows the story and can enlighten me, I'll pass it along.

I'll try to update soon.

|

|

I'll keep this short 'cause between work and home, I've been doing nothing but writing html. Time for a little fraggin' or something....

|

|

On the up-side, after 2 months of playing, I have figured out all of the troubles, bought a killer power supply, and found a peltier that rocks. With this new-found knowledge, and money spent, I have water cooler 8 up and running in its test configuration - and it kicks butt. I'll be building the final version of WC8 shortly.

On the "what's new" front, I was in the position of needing a new motherboard recently. It's time to upgrade one of our computers and I wanted a new toy anyway. With more processors than motherboards currently, I needed another board to take a PIII / Celeron2. I can honestly say that after looking at virtually every new board on the market, I'm unimpressed with the current offerings. The i815e chipset from Intel is a real letdown. You would think that Intel would take the performance up a notch from the trusty BX, but that doesn't appear to be the case. I even considered the i840 with full knowledge of the fact that buying RAM for it would mean eating baloney sandwiches for a month. However, for all the money one needs to spend to get an i840 board up and running, the performance doesn't justify the expenditure. The VIA chipsets are getting better, but VIA still has a way to go to before they'll be on even footing with Intel in the performance arena. I will say that the ability to run the SDRAM asynchronously faster than the front side bus frequency almost swayed me to the VIA chipset. If this feature was offered with the i815e, I would have been mighty tempted.

My wish list for a board included (in order of importance): the ability to read the internal diode temperature (after all, I do like playing with heat sinks!), *LOTS* of bus speeds to choose from, and ATA/66 support. On the "I want it, but can do without it" list were ATA/100, socket 370 (rather than use an adapter), and a "dual bios." Since all of these features were not available on one board, I ended up with an Abit BF6 and a Promise Ultra 66 to handle the hard disks. In an industry where components improve weekly, to end up buying last year's motherboard strikes me as a bit amusing. Anyway, the new board will allow me to swap the Asus P3-BF to my son's computer so he can give me a hand with some testing. Maybe now I'll be able to dig my way out of some pending projects.

|

|

To get myself back in "writing mode," I've put together a short piece on tearing down WC4 after seven months of constant use. I was curious to find out how well the cooler did at keeping moisture away from the critical components. I was pleasantly surprised by the outcome. You can take a look at the results here.

I have enough pictures of the whole process

of building WC7 to keep me busy explaining them for a while. I'll

try to tear myself away from the workshop long enough to get some of them

assembled into an article or two.

Until then....

|

|

So how does the 700 overclock? So far, not too well. Unlike other processors I have played with, this one does not seem to like much more than stock voltage and dropping the temperature the usual amount doesn't seem to make a lot of difference in speed. With the box stock Intel heat sink, it will clock to 840 at 1.6, 1.65, and 1.7 volts. The top internal temperatures while pushing the heck out of it remain below 117°F. If I drop the temperature with a pair of peltiers and a water cooler so that the idle temps with Rain are in the -7° range (20s without Rain) and 868 MHz is attainable (and stable - if one can tell that with only 2 days of pushing it.) High temps internally now run in the 60s. So far pushing the chip to a 133 bus for a total of 933 has not been possible. For some reason, I get worse results with the voltage set to 1.7 or higher. In fact, it seems to like 1.6 better than 1.65. It seems like I have gotten another weird chip. If I have to stay at 868, so be it. This setup is quite quick at its present speed. However, the next step for this chip is lower temps. I'm thinking along the lines of -20 at idle without Rain. This has meant some re-thinking of the radiator setup I was planning on. Did anyone else notice the "dorm sized" fridge at K-Mart (Oh Martha, I'm sorry, make that the NEW Big K) for $79 this last weekend? Looks like a good source for an inexpensive refrigerant pump....

Elsewhere:

For the cooling fanatics in the crowd,

you have to check out this thread

over at SysOpt's BBS.

The pictures are here.

This gentleman has remover the slug from his K6 and then cooled the core

with water. Now that's something you don't see every day! Thanks

to Paul for the links.

|

|

Speaking of tinkering, I've been thinking about running multiple water coolers off of a single radiator. Things are getting a little too crowded under my desk to stick another single box with radiator, pump and fans down there. I've also been toying with the idea of using ducting to direct the hot air from the radiator's output outside the room. I'll have to see if I can come up with a design that works and doesn't look like it belongs in the basement.

|

|

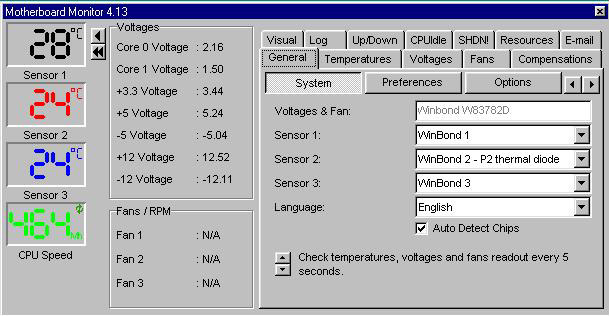

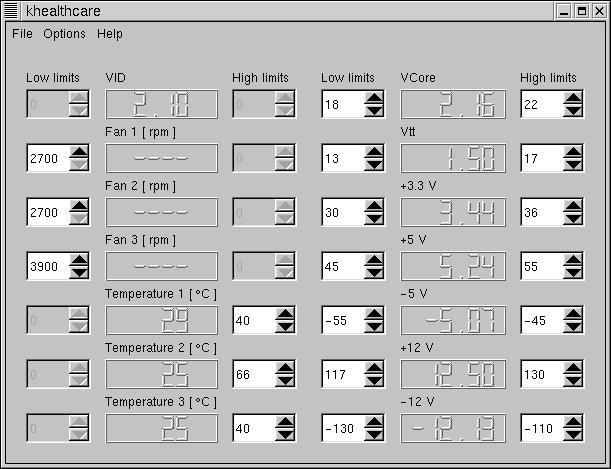

I finally have a nice temperature monitoring system set up on the Linux box. This gave me a chance to try something that I had been wondering about for a while. As you know, the CPU cooler programs use a HLT call to suspend the processor while it is idle. This results in less power consumption and a cooler processor while idle. UNIX and its variants have this call built into the operating system. I was curious if one were to switch nothing more than the operating system on a box, would the idle temperatures be similar?

To find out, I did fresh installation of

Red Hat 6.1 on one hard disk drive and a fresh installation of Win98 SE

with Rain on another. I booted up Win98 first and let it sit for

15 minutes to let the temperature reach its lowest point and took a "snapshot"

of the temperature using Motherboard

Monitor 4.13. I then shut down, swapped hard drives and booted

up Linux, let it cool for 15 minutes and took its temperature with a Lm_sensors

front end called KHealthCare.

|

|

As you can see, aside from the fact that the room temperature went up 1°C during the time I transferred disks, the temps are about the same. This is no earth shattering news - just something I was curious about. One other little item of interest to the overclocker is that Linux issues the HLT about half way through the boot-up process, where to get Rain running in Windows you need to complete the whole boot.

If you noticed that the 12 volt reading looks a little high, I've noticed that too. I'll have to keep an eye on that.

|

|

The next step is to plot the temperatures of this box with the Alpha P125 the Cele is wearing for a few days before I move to a water cooler. Since the 300A at 464 has had its temperatures well documented in a Windows box, I'm curious to see the differences in temps running Linux. It should make for an interesting week.

My apologies for the fact that this page has been "locking up" lately. It would seem despite claims that their new affiliation would help speed up the program's loading - my counter, the counter, has been a "no counter," and not loading. So much for progress. It looks like it's time to do some work in the cgi-bin and cut loose with this program.

|

|

I am a little late with this, but my requests to Abit for a new CMOS chip were answered the day following my BIOS flashing episode. A pretty quick response, but I'm glad I didn't wait. I had been through the search engines and Deja forward and backward looking for better information than is listed on Abit's site regarding the cost and how to get a new chip. Here is the info I received from Abit.

"The price for the bios chip is $10.50, in order to buy it, you can send us a check along with your request to 46808 Lakeview Blvd, Fremont, CA 94538 Please include your shipping address along with your request to us, and please make sure you put down your model number and the reversion number as well.

Best Regards,

Terry

Terry@abit-usa.com"

I hope you don't need this info, but if you do, this might save you a little time.

I haven't been in the loop on the software cooler programs lately and totally missed the introduction of CPUidle Pro. This version will work with Win2K and NT if you find yourself having trouble with the ACPI calls or are running dual processors. You can check it out at Andi's site. I guess this means that sooner or later I am going to need to update the tests.

From time to time, I get the opportunity to look at some great pictures of water cooled systems. In honor of New Zealand retaining the America's Cup, here are a couple of Kiwi sites with some nice water cooled rigs. Orthello's and Subside Overclocking. Garrie has one nice looking setup.

|

|

Many thanks go out to all of you who offered your help today. I received everything from good advise to an offer to flash me a chip on his board. (Thanks Sterling!) All of the email was appreciated and made the "little victory" all the better.

|

|

Lately, I have had so many projects going on at the same time that it has been difficult to focus on one thing at a time. I have come to the conclusion that it is probable that I did not burn up the Abit BX6r2. After some reading on the DMI Pool Data, I think I have just corrupted the information on the CMOS chip. I will give Abit a call tomorrow and have them ship me a replacement chip and see what happens. I was thinking of "hot flashing" the BIOS, but haven't been able to come up with a chip to put in to get the board up. I'll try the hot flash when I get the new chip from Abit.

On the "new technology" front, I just got sent an interesting link from Justin that there is a new peltier device in the works that is supposed to be able to get a Delta T of 200° Kelvin. This would be quite an interesting advancement from the present peltiers, though I seem to have enough trouble insulating setups with a temperature difference of 60°K. You can take a look at the article over at EE Times.

|

|

This is a self-contained, water cooled unit with thermostatically controlled, variable-speed radiator fans. It does a pretty good job of cooling the old AMD K6-233 toaster, keeping the back side of the processor to about 90°F while pushing looped timedemos of Quake 2 in X-Windows in a 70°F room. Frame rates? Don't ask. It was also running Apache, Sendmail, and serving files at the same time. Can we spell s-l-o-w....

I'm about half way through the write-up on

the project. With any luck, it should be up in a couple days.

|

Ramblings: Over the last few months, I have received a lot of mail with questions about building the ultimate water block / peltier setup. "What about building a block to handle six 72 watt peltiers and get the CPU temp to minus whatever..." My thoughts on the subject, at this point, are:

WC4, which is being run with 2 - 30 mm peltiers, typically cools the processor's internal thermistor to 15°F to 20°F at idle without a software cooler (Rain). With Rain, those temps are -7° to -12°F. Without any additional cooling of the water for the block, the system will boot a Celeron 366 into Windows 98 SE at 683. It is certainly not stable at this speed, but does boot and run some light applications. So what happens if I chill the water to get the internal processor temperature in the -40°F range? Same thing. It still boots into Windows - and is still too unstable to run as anything other than to boast "see what speed I got!" Does getting the processor down to -40 help me to boot into Windows at the next setting on the P3B-F (133 MHz)? No. Unfortunately, doubling the rated speed of ANY of my processors has not been possible. Now, this might be the luck of the draw - with me as the unlucky one - but I have not seen many success stories of people doubling their processor's rated speed. There IS a physical limitation to the amount you can overclock a given processor - frozen or not.

For me, the bottom line becomes "why cool the chip more than I need to?" If you've followed my water cooling projects, you know that condensation is a real concern and the colder you get the processor, the colder the components around the processor get. This means that there is a greater potential for condensation. If I am not going to gain speed or stability from going colder, then why increase the chances of condensation?

|

|

(click to enlarge) |

As one of the goals of this project was to reduce the noise produced by the multiple fans cooling the server case, I wanted to be able to throttle back the big 120 mm Panaflow fans that Ian at 2CoolTek is sending over. I found a couple simple circuits using an op amp, mosfet, and thermistor that I combined to produce a variable voltage to the fans based on temperature. With the sensor attached to the radiator, the two test fans were running at about 7 volts at 65°F. At 88°F they're full voltage. As the workshop is a bit on the chilly side, I'll have to wait until I assemble the cooler setup on the server to find out if further tweaking will be necessary.

|

|