|

Download template.doc 130 Kb

Materials

Heat sink (Main)

Fans

Heat sink (Rear) Allstar Shop

Peltier

"Y" Adapter (to connect peltier to HD power cable) Radio Shack

Plates

Screws, nuts, washers, and springs

Templates

Click the link at the top of the page

to download the templates in a MS Word Document.

The word doc will print the templates

in the proper size.

Hot and Cold Plates

These plates are cut from 3/16" aluminum

sheet stock.

Insulation

The insulation is sized for a 30mm X 30mm

Peltier.

Trim according to the TEC you use.

The left and right

edges may also be trimmed to allow a good

fit in the

Celeron's mount on to the motherboard.

I used Abit's

PII motherboard mount.

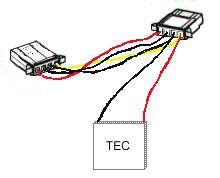

TEC Connection

The TEC was wired to a 486 heat sink fan

splitter cable

I had left over. The splitter is attached

in between the hard

drive and its power connector. The

yellow splitter wire is

+12 volts and the black is ground.

The positive TEC wire

(red) is connected to the yellow and black

to black. Make

sure you power up the TEC to check which

side is the cold

side before mounting it. Don't run

it for longer than necessary

to determine which is hot and which is

cold.

Assembly

It is important that the mating surfaces are flat and as smooth as you can get them. This is especially important for mounting the heat plate to the heat sink. As I discussed in the Celeron article, I use successively finer and finer grades of wet / dry sand paper taped to a piece of glass or other flat surface to lap the surfaces flat. Before applying thermal compound to the surfaces, you should not be able to see any gap between the plate and sink when held up to a light. If you come across a heat sink with a thick base (> 3/8"), the heat plate will probably not be necessary.

There is not too much to the assembly once the plates are cut and drilled. Make sure that the peltier is installed with the cold side facing the Celeron and that a thin coat of thermal paste is applied between each metal surface. Tighten the screws in an "X" pattern to keep the pressure constant and to avoid crushing the TEC. Once the springs are about half way compressed, twist the plates and SEPP back and forth a few times to even out the thermal paste and then tighten the screws until the springs are almost entirely compressed.

If you decide to build this project, drop me an email and let me know of the outcome. I'd be interested to get some more input on the success rates.

Jim

|

Intro . |

voltage limits |

high volts |

trying peltiers |

second attempt |

stable @ 504 |

lower voltage |

case heat |

final thoughts |

build it |